Передвижной горизонтальный поток воздуха древесные чипы брикеты углеродное волокно biocharer печь CE ISO отходы древесный уголь машина

- Категория: Carbonization Stove >>>

- Поставщик: Henan,Zhangsheng,Environmental,Protection,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 8449.2 $* | 8871.38 $* |

| Aug-16-2025 | 8378.83 $* | 8797.63 $* |

| Jul-16-2025 | 7029.46 $* | 7380.59 $* |

| Jun-16-2025 | 8236.36 $* | 8648.48 $* |

| May-16-2025 | 7171.99 $* | 7530.51 $* |

| Apr-16-2025 | 8094.37 $* | 8499.52 $* |

| Mar-16-2025 | 8023.92 $* | 8424.50 $* |

| Feb-16-2025 | 7952.15 $* | 8350.24 $* |

| Jan-16-2025 | 7881.58 $* | 8275.81 $* |

Характеристики

Raw material can be Wood log, tree, tree branch, wood briquette, coconut shell, palm nutshell, Walnut Shell, Macadamia nutshell, bamboo, and other nut shell or hard raw material.

If your raw material is biomass wood sawdust, there are several steps to make briquettes:

If your raw material is biomass wood sawdust, there are several steps to make briquettes:

1. The frist step is crush biomass wood sawdust become small size, less than 3mm.

2. The second step is dry raw biomass wood sawdust, in order to reduce the moisture less than 12%.

3. The third step is use press machine produce briquette.

4. The fourth step is carbonize briquette become charcoal. Click the picture to view all the parameters and detailed introduction of the hoisting carbonization furnace production line

If your raw material is Toner, there are several steps to make briquettes:

If your raw material is Toner, there are several steps to make briquettes:

2. Rotary dryer/Air flow dryer: if you raw material moisture higher 30%, before carbonizing it need to dry.

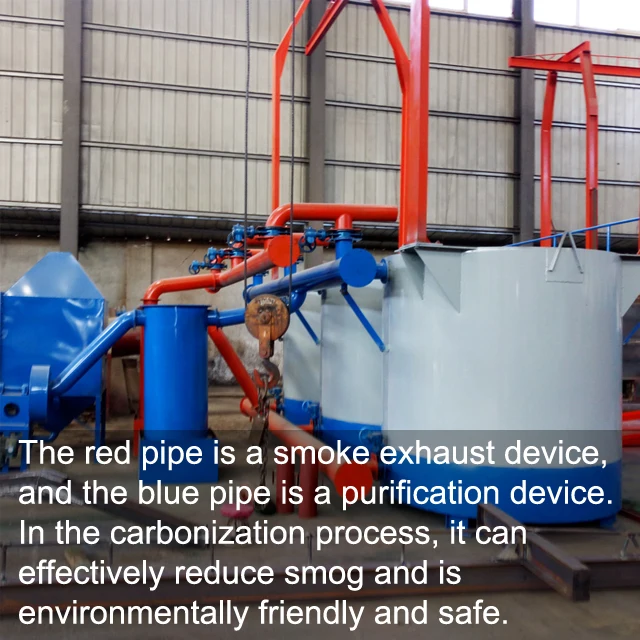

3. Continuous carbonization furnace: carbonizng the raw material into charcoal.

4. Charcoal crusher:crusher the charcoal into less than 5mm powder.(Choose configuration)

5. Charcoal and binder mixer: mixing charcoal powder and binder(we supply you formula).

6. Charcoal briquette machine:we supply all kinds of charcoal briquette machine.accordingto your require.

7. Charcoal briquette dryer:Drying the charcoal briquette and then can packing it directly.(Choose configuration)

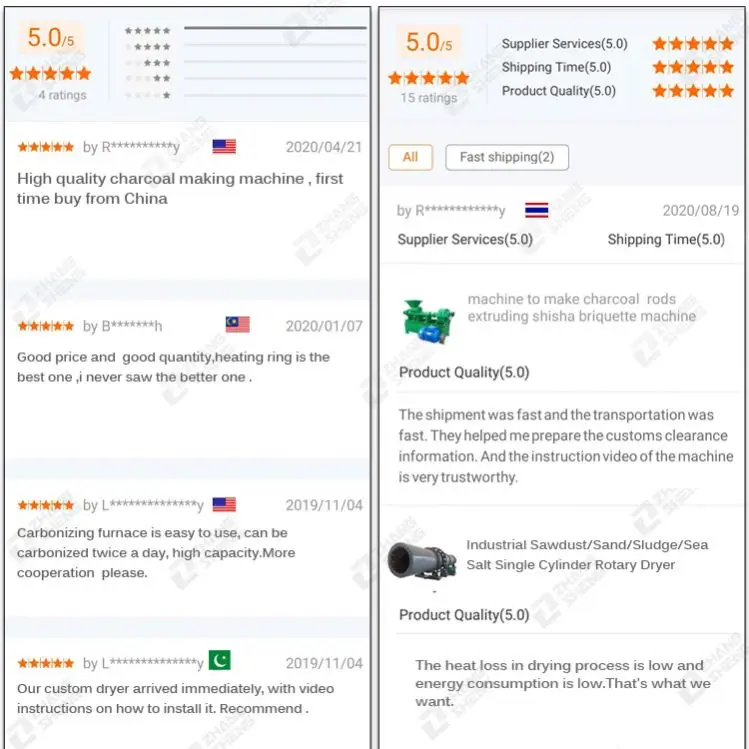

We are a professional charcoal machine manufacturer in China. We have more than 20 years of experience in manufacturing charcoal machines. We can provide you with the following services:

1. We will provide you with all wearing parts of the equipment for whole life, and give you the best factory price.

2. After the ship leaves the loading port, when we receive the bill of lading, we will send you the proforma invoice, packing list, certificate of origin and other related documents together for your customs clearance.

3. Before the equipment is shipped, we will test the machine. After loading the machine into the container, we can send the loading picture to you.

4. We have long-term cooperation with many famous freight forwarder companies. We also provide CE, ISO9001, CO, Form E, COC, CIQ and other certifications to help customers from different countries to clear customs.

5. We send engineers to your working site to help you install and debug equipment, build factories and train operators, At the same time, the charcoal production technology will be passed on to customers.

Q1. What's your advantage? How to install?

1) We have 15 years of working experience. The real production plant of 200 workers has the most professional technology and team. Price is more advantageous.

2) Provide installation videos, or arrange for engineers to communicate with you directly on installation methods.

3) We have overseas engineer services and can provide free training for on-site staff.

Q2. How long is your delivery time?

If there is stock, it usually takes 5-10 days. It takes 20-30 days to customize the equipment according to your requirements.

Q3:What if the machine is damaged?

One-year warranty and comprehensive after-sales service. After this period, we will charge a lower fee to maintain after-sales service.