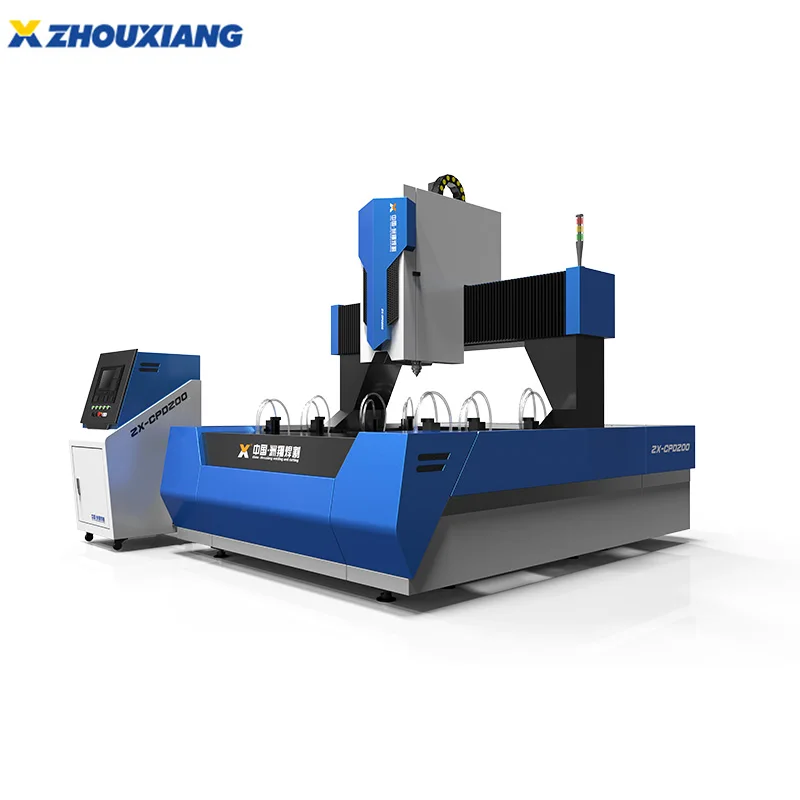

Высокоскоростной сверлильный станок с ЧПУ серии

- Категория: Сверлильные станки >>>

- Поставщик: Wuxi,Zhouxiang,Complete,Set,Of,Welding,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 23800.55 $* | 24990.52 $* |

| Aug-16-2025 | 23600.91 $* | 24780.69 $* |

| Jul-16-2025 | 19800.22 $* | 20790.43 $* |

| Jun-16-2025 | 23200.90 $* | 24360.73 $* |

| May-16-2025 | 20200.82 $* | 21210.58 $* |

| Apr-16-2025 | 22800.61 $* | 23940.56 $* |

| Mar-16-2025 | 22600.93 $* | 23730.40 $* |

| Feb-16-2025 | 22400.47 $* | 23520.44 $* |

| Jan-16-2025 | 22200.17 $* | 23310.40 $* |

Характеристики

Product Application

ZPZ digital driller employs AC srevo motor to drive the X axis and Y axis, while its Z axis is positioned by high accuracy raster.By using semi-closed closure digital control system,the machine has reliable performance.The operation of the machine can either be automatic or manual. This machine is widely used in steel frame contruction.

Technical Parameter | ||||||

Model | ZPZ160 | ZPZ200 | ZPZ400 | |||

Drilling diameter | φ50 | φ60 | φ60 | |||

Max dimension of workpiece | 1600×1000×80mm | 2000×1500×80mm | 2000×1500×80mm | |||

Rotary speed of main shaft | 130-400r/min | 130-400r/min | 130-400r/min | |||

Feeding type of main shaft | Hydraulic | lead screw | lead screw | |||

Quality of moveable working platform | 2 | 2 | 2 | |||

Workpiece can be tooled for once | 4pcs | 4pcs | 4pcs | |||

Clamping type | Hydraulic | Hydraulic | Hydraulic | |||

X and Y axis fast moving speed | 12m/min | 12m/min | 12m/min | |||

1. High production efficiency: There are two movable worktables. When one table is drilling, the other can handle parts (load or unload) at the same time, so the machine can do non-stop drilling; with four processing point it can load at the same time 1 ~ 4 parts for processing; 12 movable hydraulic clamps were equipped inside the worktables, which can quickly and conveniently load and unload parts; drilling head’s 12m/min rapid positioning; the spindle head adopts 3 different lengths quick-change drill chuck, which can be chosen by the drill length and thickness.

2. High precision machining: X/Y-axis is driven by AC servo motor ball screw driving system; power head and worktable are moving in a straight line rolling guide.

3. It adopts Guangzhou CNC GSK980MDc drilling system. This system has powerful function and can control 5 feeding axis with high control precision. Also equipped with Guangzhou CNC GS2000T series servo driving unit, Guangzhou CNC 110SJT servo motor with stable running and high precision position control.

4. Safe, reliable: when a table is loading and unloading the work-piece, the power head will not move to this area; numerical control system, electrical actuators, hydraulic components use brand-name imported parts.

5. It is equipped with automatic chip cleaner, cutting fluid adding automatically, also equipped with gas gun which can realize dust pneumatic blowing.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.