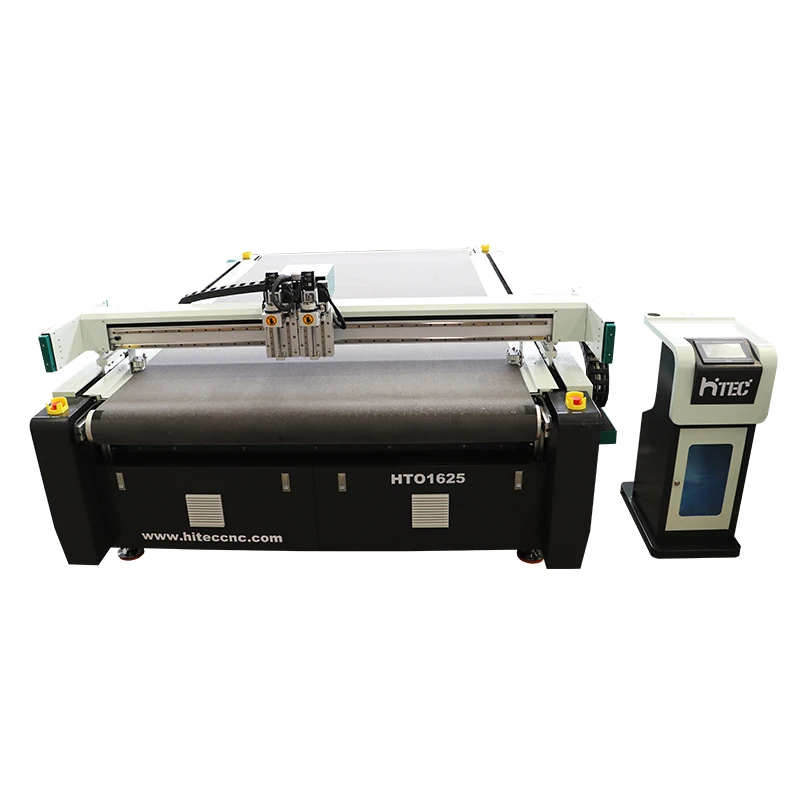

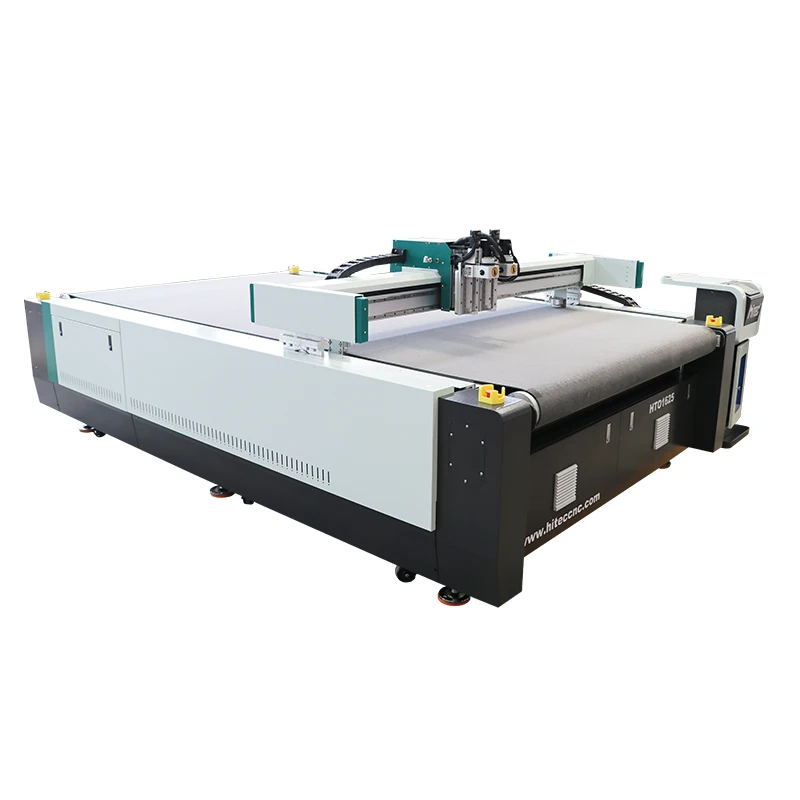

1625 ЧПУ генераторный нож для резки окон полиэстер плотные роликовые жалюзи

- Категория: Раскройная машина >>>

- Поставщик: Jinan,Hitec,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.8 $* | 0.12 $* |

| Aug-16-2025 | 0.34 $* | 0.9 $* |

| Jul-16-2025 | 0.86 $* | 0.79 $* |

| Jun-16-2025 | 0.68 $* | 0.52 $* |

| May-16-2025 | 0.31 $* | 0.97 $* |

| Apr-16-2025 | 0.7 $* | 0.39 $* |

| Mar-16-2025 | 0.69 $* | 0.41 $* |

| Feb-16-2025 | 0.31 $* | 0.83 $* |

| Jan-16-2025 | 0.91 $* | 0.65 $* |

Характеристики

1625 CNC oscillating knife cutting machine for 100mm thick foam

Application of oscillating knife cutter machine

Digital Fabric Oscillating Knife Cutter Plotter Machine For Sale can process fabric,knitting vamps, non-woven, leather, rexine, cotton, felt, silk, lace, polyester, fleece , soft shell,jeans,alcantara,neoprene ,Corrugated board, cardboard, white board,gray board, sticker, PVC film,foam board, artificial leather, leather, gasket,sponge, Prepreg,acrylic, honeycomb board, fiberboard, epoxy resin board, organic glass, car mat, fiber,composite material and other soft materials, etc.

PARAMETER of oscillating knife cutter machine | ||||

Parameter/Model | HTO-1625 | HTO-2030 | ||

Rated Power | 12KW | 14KW | ||

Dimension | 3391*2723*1235mm | 3891*3173*1235mm | ||

Max Working Size | 2500*1600 | 3050*2050 | ||

Multi-functional Cutting Head | Replaceable oscillating knife, half knife, full knife, oblique knife and creasing wheel etc. | |||

Tools configuration | Various cutting tools, creasing wheels, pen, cross positioning laser | |||

Safety | High sensitivity infrared induction (optional) | |||

Moving Speed | Max. 1200mm/s | |||

Cutting Speed | Max. 800mm/s(please set the speed according to the material) | |||

Material Applicable | Corrugated paper, non woven fabric , PVC expansion sheet, KT board, foam board, grey paperboard, cardboard, vehicle sticker, adhesive sticker etc. | |||

Cutting Depth | Max 100mm (depends on the material) | |||

Material Fixing Method | Strong power vacuum absorption and intelligence Partition | |||

Resetting Positioning Accuracy | Max 0.01mm | |||

Mechanical Precision | Max 0.02mm | |||

Drive System | Steel Simultaneous Belt, AC Panasonic servo motor. Linear guide rail | |||

Control System | digital oscillation control systerm | |||

Display | English LCD touch screen | |||

Data Transmission | Ethernet | |||

Command | HP-GL compatible format | |||

Buffering Capacity | Standard--4GB | |||

Rated voltage | Customized | |||

Hitec Cnc Option : - machine size can be customized according your request - auto feeding system - multi function cutting head - auto nesting cutting software - CCD camera visual cutting system - Projector cutting system | ||||

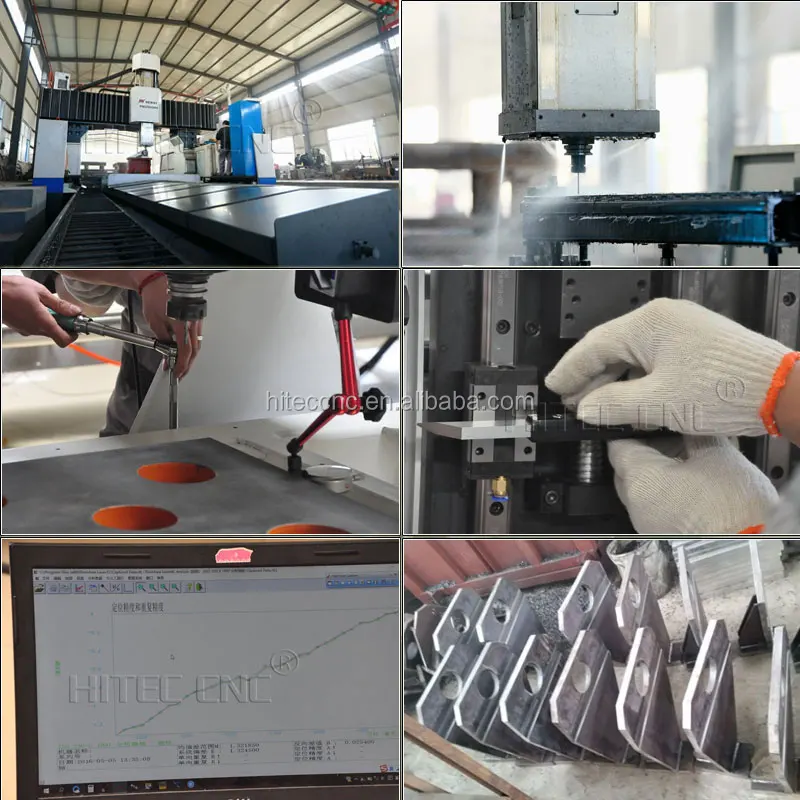

Features of oscillating knife cutter machine

1. Imported Taiwan square linear guide and Japanese servo motor ensure high accuracy, fast cutting speed and stable

working performance.

2. Whole machine is welded with thick square seamless steel structure and treated with high temperature, ensures

high accuracy, no deformation and super long service life

3. The whole piece aluminum platform is honeycomb structure, not easy to deform, sound-absorbing, etc.

4. Hitec digital cutting machine was designed easy to install, set-up and operate.

5. Being equipped with infrared sensor and emergency stop devices, guarantees safety.

6. Cutting by knife not laser, no air pollution , no burnt edge, cutting speed is 5-8 times faster than laser cutting machine.

Advantage of oscillating knife cutter machine

* Cutting precision

The precision of Digital Fabric Oscillating Knife Cutter Plotter Machine For Sale that every mechanical manufacturer can provide now is about ±0.2mm,there should be a complete procedures for test fiberglass cutting accuracy before delivery.Through testing, we can fully grasp the flatness of the cutting platform and the synchronization control level of the control system

* Cutting speed

After meet the demand of fiberglass cutting precision then we can talk about with the cutting speed,HITEC CNC fiberglass knife cutting machine adopt Japan Yaskawa servo motor and driver, provide optimum cutting performance and fast, accurate results.

* Automatic layout optimization

Our fiberglass fabric cutting machine operation simple, easy to understand and not complicated,the graphics library should be more flexible and AutoCAD graphics also can be used in typography.

* Easy maintenance

The machine is equipped with I/0 signals and sensors,if the some device of the fiberglass cutting cnc machine meet problem,you see the I/0 signal state on the LED screen,it is more convenience and easy to find fault and replace the parts.

* Saving consumption

Our fiberglass oscillation cutting machine with fast cutting speed anf high cutting precision,save time,save labor and save cost.machine cutting with knife blade,no burn no smoke is good to the environment protection .

* More safe for operation

Equipped with infrared security devices , can effectively protect the safety of the operator

3. Put wooden boards on the table to prevent the table from being attrited. The accessories are fixed on the wooden boards of the machine with packing straps to prevent the accessories from moving.

4. The anti-rust film bag is put on the machine to prevent rust, water and scratched. The plastic film is wrapped around the

anti-rust film bag for reinforcement.

5. Then pack it in a fumigation free plywood box.

6. Finally fix the wooden box with steel belt.

Company Information

Established in the year 2002,An ISO 9001 Firm.We are manufacturer and deverlops of the high technology machines.Hitec products are used in a wide variety of industries,markets and applications thoughout all over the world.Hitec is highly committed to offering the most advanced,capable and efficient manufacturing technology backed by unsurpassed service and support.

We offer cnc wood router,cnc laser,cnc plasma,cnc parts.

All the machine parts Assembe by our machine milling and lathe machine,can be guarantee the machine precision and fast delivery time

We welcome all our buyers come to visit our factory for directly free training, our professional engineer will support you to study the machine operation.

We will supply machine operation manual, training videos and machine parameters, our engineer will supply online machine installation and training.

The customers’ technicians can keep in touch with our engineer at any time, through wechat/whatsapp/mobile phone or email, our engineer will help to solve your problems as soon as possible.

If customer need, we will send our engineer to the customers’ place to provide install and train the customer to use the

machine,our engineer will stay at customers’ place for 5-7days,customers should pay the round-trip airkets/hotels/food for our engineer.

our products can meet the needs of users to the greatest extent, and at the same time make the customer's investment play the

largest comprehensive economic benefit.

user's reasonable temporary needs;

3. Collaborate friendly with users to deliver qualified products.

Except the damage is artificial, we are responsible for offering the fittings free of charge during the guarantee period, but you

need to send the damaged fittings to us by courier with your charge before we send back the alternative fittings to you. Out of

the guaranteed period, should the parts required to be repaired or replaced, if any, the parts will be charged.

Contact Us

JINAN Hitec Machinery Co.,Ltd

Adress:Room 222,Mingfu build No.689, Hangyun road, Licheng district, Jinan SHANDONG, P.R.CHINA

Website: www.hiteccnc.com

Email:sales(@)hiteccnc.com Wechat :chenyanyang14

Skype: +86-17862864348 Cell phone: +86-17862864348

"Customers satisfaction is our greatest goal" ---Hitec Group