Автоматический станок для изготовления жестких коробок HM-ZD2418 небольших бумажная коробка в магазин

- Категория: Упаковочные формовочные машины >>>

- Поставщик: Guangdong,Hongming,Intelligent,Joint,Stock,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.98 $* | 0.54 $* |

| Aug-18-2025 | 0.75 $* | 0.29 $* |

| Jul-18-2025 | 0.13 $* | 0.57 $* |

| Jun-18-2025 | 0.52 $* | 0.26 $* |

| May-18-2025 | 0.79 $* | 0.99 $* |

| Apr-18-2025 | 0.59 $* | 0.51 $* |

| Mar-18-2025 | 0.6 $* | 0.75 $* |

| Feb-18-2025 | 0.24 $* | 0.89 $* |

| Jan-18-2025 | 0.54 $* | 0.63 $* |

Характеристики

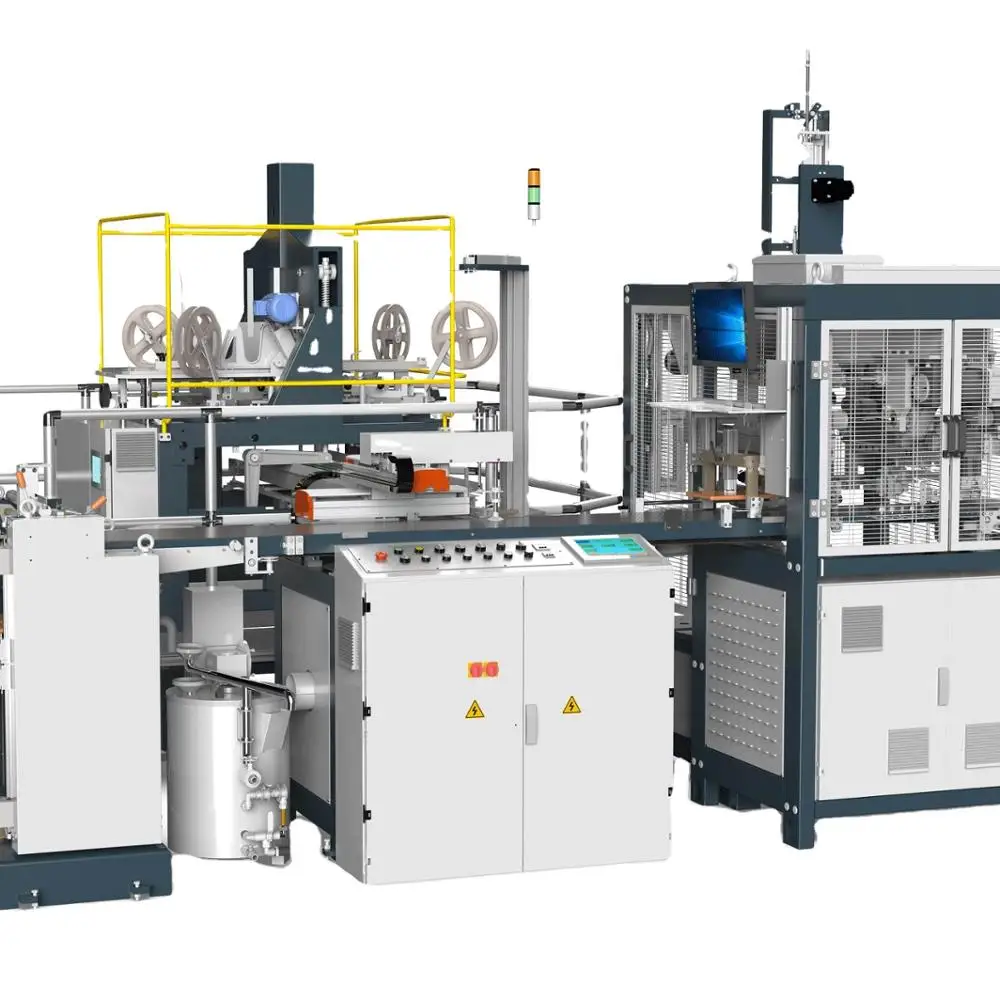

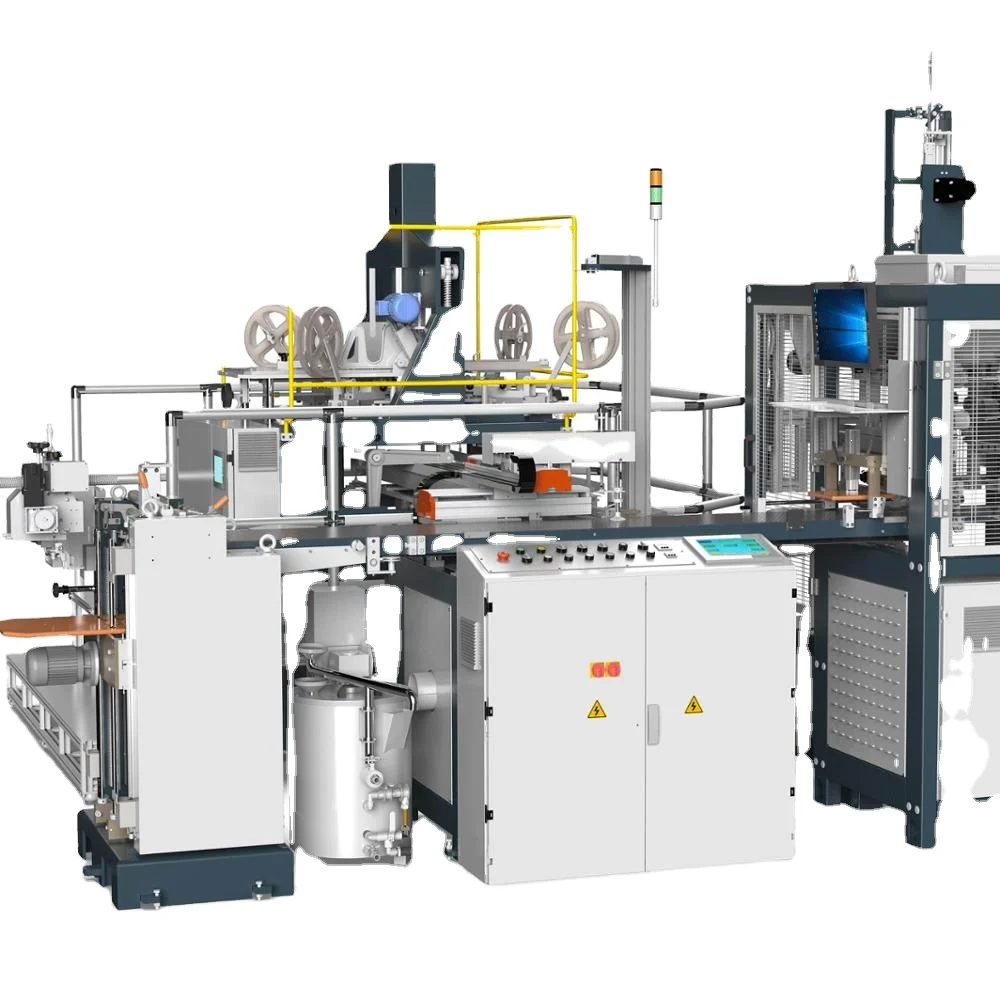

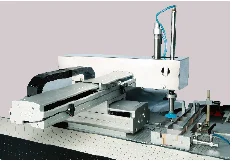

HM-ZD2418/HM-ZD2418PLUS Automatic Rigid Box Machine

HM-ZD2418/HM-ZD2418PLUS Automatic Rigid Box Machine is an automatic intelligent equipment for the small sizes premium box, it is suitable to make various of rigid boxes types in mass production, such as high-grade jewelry boxes, ornaments boxes, gift boxes, watch boxes, pencil boxes, candy boxes, souvenir boxes, cosmetic boxes, etc.

This machine adopts PLC and man-machine control, error auto stop and display, camera tracing system, and can automatically feed cover paper, feed greyboard, paste four corners, spot greyboard, lift box, fold corner edges and wrap box.

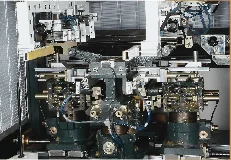

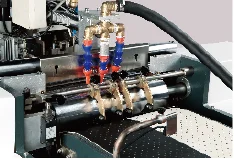

The feeder, the gluer and the conveyor are driven by servo system, the machine has continuously variable transmission and enjoys high accuracy, easy adjusting, and efficiency. Double colors conveyor can save the time for changing to another color belt, which is Hongming's patent. The spotting unit adopts Germany camera with 5 million pixel and robot arm to pick and spot the greyboard, enhancing the spotting accuracy to ±0. 05mm. The forming unit

employs Japan THK linear slider and virtual electronic cam driving system, guaranteeing the stable quality and fluent movement and enlarge the folding-in depth and corner edges.

Features and function:

1. Suit to all kinds of rigid boxes in mass production;

2. Parameters adopts computer digital setting;

3. Auto error stop and display;

4. Automatically feed paper and greyboard;

5. 24-hours control for glue pre –heating;

6. Corner pasting part with independent man-machine control and heating

system;

7. Adopt servo and PLC control;

8. Spotter by camera tracing system and SCARA (Selective Compliance

Assembly Robot Arm) (spotting accuracy ±0.05mm);

9. Wrapper can automatic lift and wrap box;

10. Automatic control system for glue viscosity (optional).

Model |

| HM-ZD2418 | HM-ZD2418plus |

Greyboard size D=Length, C=width | D(Max) | 400mm | 510mm |

D(Min) | 65mm | 65mm | |

C(Max) | 320mm | 410mm | |

C(Min) | 55mm | 55mm | |

thickness | 0.5-3mm | 0.5-3mm | |

Paper size B=length ,A=Width | B(Max) | 450mm | 600mm |

B(Min) | 110mm | 110mm | |

A(Max) | 305mm | 455mm | |

A(Min) | 70mm | 70mm | |

Thickness | 80-160gsm | 80-160gsm | |

Finished box size L=length, W=width H=height | L(Max) | 240mm | 350mm |

L(Min) | 45mm | 45mm | |

W(Max) | 160mm | 250mm | |

W(Min) | 35mm | 35mm | |

H(Max) | 80mm | 80mm | |

H(Min) | 10mm | 10mm | |

Paper corner edge |

| 10-100mm | 10-100mm |

Folding in depth |

| 8-80mm | 8-80mm |

Paper pile height max |

| 600mm | 600mm |

Greyboard pile height max |

| 400mm | 400mm |

Glue tank volume |

| 20L | 20L |

Air supply |

| 480L/min, 0.8MPa | 480L/min, 0.8MPa |

speed |

| ≤30pcs | ≤30pcs |

Total power |

| 29kw/AC380V | 29kw/AC380V |

Power consumption |

| 7.5kw/h | 7.5kw/h |

Net weight |

| 4000kg | 4200kg |

Machine dimension |

| 4500*3500*3000mm | 4500*3500*3000mm |

Product Output

COMPANY INTRODUCTION

DEVELOPMENT COURSE

CERTIFICATES

BOXES