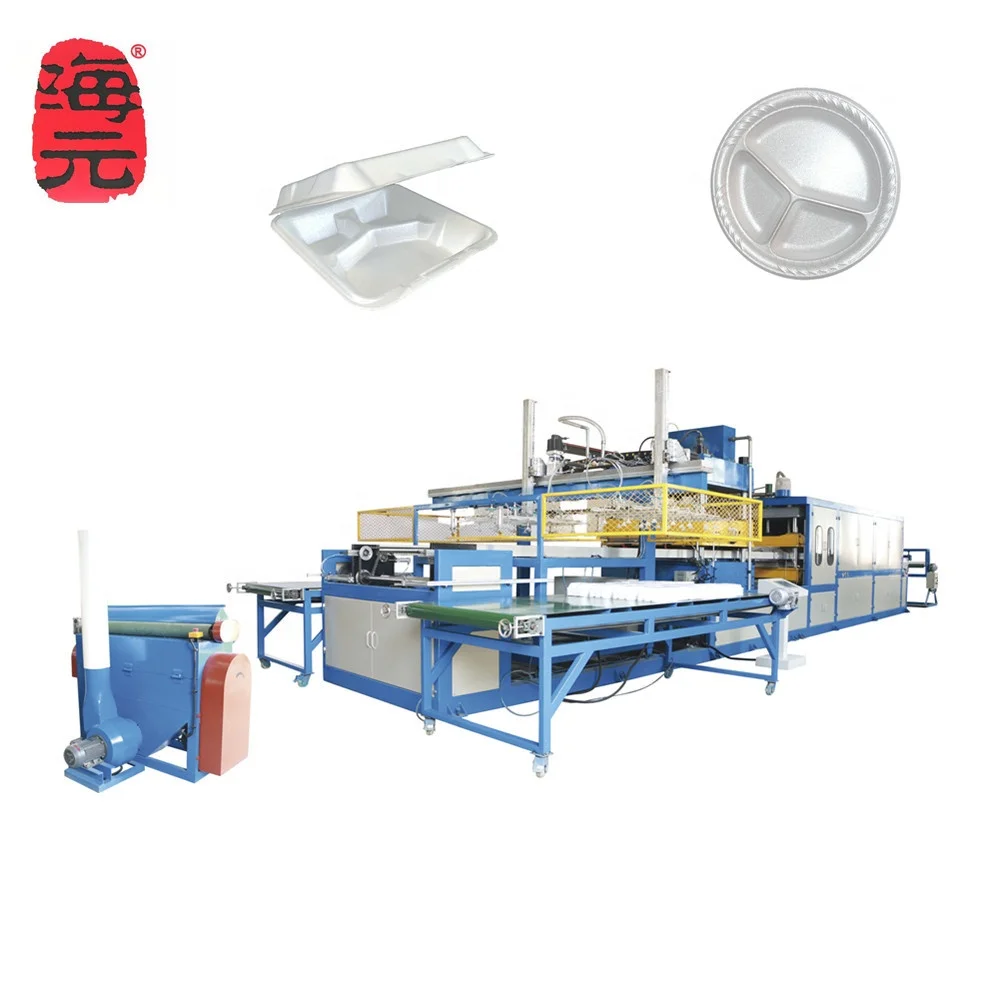

Низкая цена пенополистирол машина для производства бумажных стаканчиков тарелок пищевых контейнеров

- Категория: Plastic Product Making Machinery >>>

- Поставщик: Longkou,Haiyuan,Plastic,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 39270.73 $* | 41234.87 $* |

| Aug-15-2025 | 38940.53 $* | 40887.91 $* |

| Jul-15-2025 | 32670.51 $* | 34304.62 $* |

| Jun-15-2025 | 38280.57 $* | 40194.95 $* |

| May-15-2025 | 33330.69 $* | 34997.16 $* |

| Apr-15-2025 | 37620.88 $* | 39501.45 $* |

| Mar-15-2025 | 37290.35 $* | 39155.33 $* |

| Feb-15-2025 | 36960.80 $* | 38808.69 $* |

| Jan-15-2025 | 36630.77 $* | 38462.42 $* |

Характеристики

1.PS foam thermocol plate / tray / dish making machine

2.PS foam pizza box/food box making machine

3.PS foam bowl making machine

4.Disposable take away food container making machine

5.PS foam absorbent tray/plate/dish making machine

6.PS foam egg tray / wine tray making machine

7.PS foam hamburge box making machine

8.PS foam false ceiling machine

9.PS foam sheet extrusion line

1.PS foam sheet extrusion line

PS foam sheet extrusion line adopts Gentian type double-stage series high foam technology.The raw material is general polystyrene granule.In the extruding process, vesicant is injected at high pressure.After extruding,foaming cooling,shaping and hauling off, it is winding to finished PS foam sheet rolls.

In our factory, we produce not only extruder but also PS foam sheet roll, we can produce different thickness, different hardness, different color sheet roll, if you no experience,don't worry, we can help you!! and when you visit our factory , can see the running machine

PS foam sheet extrusion line parameter | ||||||||||

parameter | unit | HY-75/90 | HY-105/120 | HY-110/130 | HY-135/150 | |||||

Capacity | kg/h | 80-100 | 200-240 | 230-260 | 280-360 | |||||

sheet thickness | mm | 1-4 | 1-4 | 1.5-5 | 2-5 | |||||

sheet width | mm | 640-1080 | 640-1080 | 800-1080 | 900-1080 | |||||

foaming rate | 10-22 | |||||||||

cooling method | wind&water cooling | |||||||||

cutting method | single | |||||||||

butane gas pressure | Mpa | 0.9-1.2 | ||||||||

installation power | kw | 160 | 200 | 260 | 320 | |||||

installation demision | m | 24*6*3 | 30*6*3 | 32*6*3 | 35*8*63 | |||||

power supply | 3phase 380v50Hz 3phase 220v60Hz | |||||||||

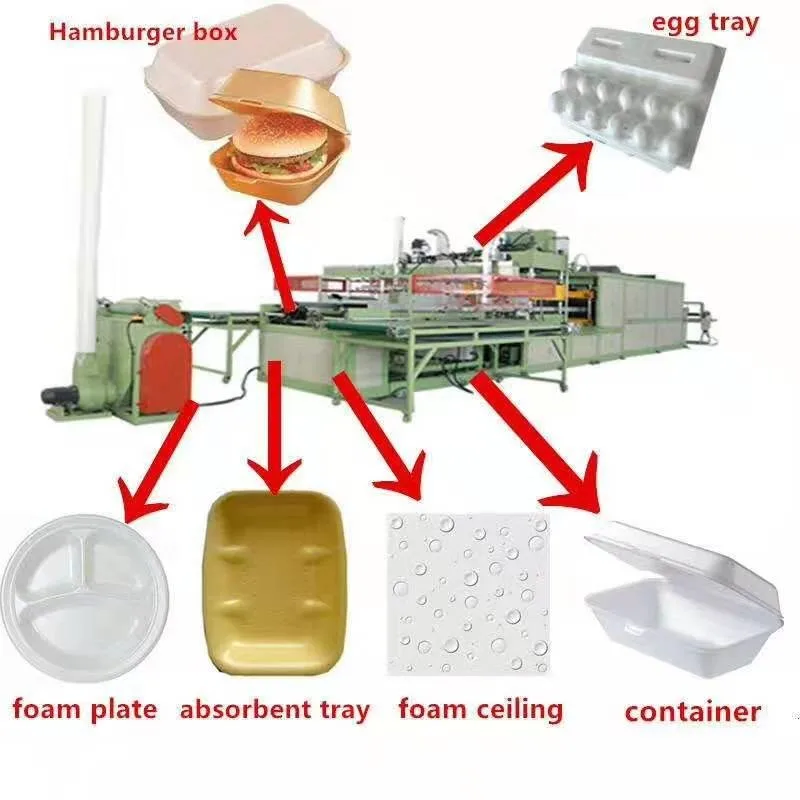

2.PS foam thermocol plate/ tray/food box/take away food container making machine

PS foam thermocol plate/tray/take away food container making machine ---- Main features

1)polystyrene foam trays machine is an all-powerful thermal forming machine with integration of vacuum forming and cutting and stacking

2) polystyrene foam trays machine production line can produce PS foam food box,disposable foam plate,take away food container,foam egg tray,hamburger box, foam plates/bowl,fruit tray ,foam absorbent tray, foam ceiling etc.It is widely used to pack the heat and frozen food in supermarket,store and so on.

3)Take away food container making machine adopts remote infrared ceramic heater and heating pipe in heating zone, which the machine get the most stable temperature.

4)PS foam lunch box making machine adopts temperature digital system,which is convenient for the workers to know the temperature of each heating zone quickly

5) PS foam thermocol plate/tray /take away food container making machine adopts PLC controller,touch screen to control the working programmer.the PLC can storage more than 10 set molds information, when you change mold no need to set data again.it is easy to operate.

PS foam thermocol plate/tray/take away food container making machine parameter | ||||||||

parameter | unit | HY-1100/1100 | HY-1100/1250 | HY-1100/1400 | ||||

Forming area | mm | 1100*1100 | 1100*1250 | 1100*1400 | ||||

cutting off height | mm | 160 | ||||||

produciton efficiency | s/die | 3-4 | ||||||

capacity | pieces/day | 400000 pieces | 500000 pieces | 600000 pieces | ||||

installation Dimension | m | 19*6*3 | 21*6*3 | 24*6*3 | ||||

installation powder | kw | 150 | 160 | 180 | ||||

power supply | 3phase 380v50Hz 220v60Hz | |||||||

3.Crusher and recycling granulator

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the PS foam disposable plate box machine

* Engineers available to service machinery overseas.

*Our salesman will be 24 hours online for you to solve equipment problems

Packaging | ||

Size | 21m * 6m* 3m | |

Weight | 15T | |

Packaging Details | After the PS foam thermocol plate/tray /take away food container making machine finished, we will pack it in wood box or plastic PE film and there have steel frame in it.according to customers special requirement. | |

Longkou Haiyuan Plastic Machinery Co.,Ltd

Haiyuan Plastic Machinery Co.,Ltd founded in 1999 is a professional manufacturer in producing PS foam sheet extrusion line, PS foam thermocol plate/tray /take away food container making machine, PS fast food box(disposable products) production line etc.We specialized in plastic machinery for 20 years with strong technology and accumulated vast experience. Our machines have been exported to Russia, Egypt, Turkey, Malaysia and Thailand etc.

PS foam thermocol plate/take away food container making machine----details introduction

Machine Parts

Name: Chain track

Brand: Haiyuan

Original: China(our company patent)

Features:

Less nosy, wear-resistant,light weight, high accuracy,long working time, keeping the balance of the chain running

Machine Parts

Name: PLC controller

Brand: Mitsubishi

Original: Japan

PLC controller can storage more than 10 sets mould information with memory founction and can memory all the temperature control,when change the mould.we needn't to set the data again,it is easy to operate.

Machine Parts

Name: Integrated temperature control mould

Brand: Delta

Original: Taiwan

Domestic famous brands

Machine Parts

Name: servo motor

Brand: Delta

Original: Taiwan

PS foam thermocol plate/tray /take away food container making machine sheet feeding and robot arm adopts servo motor control

Machine Parts: