Высокая интенсивность 150 мм черный/зеленый пластик Hdpe Geocell волокна для дороги железной стопорной

- Категория: Геоячейка >>>

- Поставщик: Shandong,Luyida,New,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.76 $* | 0.1 $* |

| Aug-20-2025 | 0.30 $* | 0.30 $* |

| Jul-20-2025 | 0.51 $* | 0.63 $* |

| Jun-20-2025 | 0.33 $* | 0.39 $* |

| May-20-2025 | 0.82 $* | 0.13 $* |

| Apr-20-2025 | 0.61 $* | 0.90 $* |

| Mar-20-2025 | 0.4 $* | 0.38 $* |

| Feb-20-2025 | 0.2 $* | 0.25 $* |

| Jan-20-2025 | 0.34 $* | 0.9 $* |

Характеристики

Factory manufacture customized HDPE plastic geocell grid

Product Introduction

Geocell is a new type of high strength geosynthetic material which is popular at home and abroad. It is a three-dimensional meshcell structure formed by high strength welding of reinforced HDPE sheet material.Due to engineering needs, some need to be drilled in the diaphragm.During construction, it can be stretched into a network and filled with loose materials such as soil, gravel,concrete, etc., to form a structure with strong lateral restrictions and large stiffness.

Product features

1.It’s extractile,flexible to fold and convenient for transportation.

2.It can be filled with soil, gravel,earth,macadam and so on when being stretched into network.

3.It has light material, wear resistance, acid and alkali resistance, anti aging.

4.It is anti-skid and anti-deformation and also has a higher lateral limit, which can reduce the thickness of roadbed.

Production type

Textured Perforated Geocell

Smooth Surface Geocell

Note:

According to different engineering requirements, we can customize a variety of sizes.

Materials Properties | Test method ASTM | UNIT | |

Cell Height | mm | 75 100 150 200 | |

Polymer Density | D1505 | g/cm3 | 0.935-0.965 |

Environmental Stress Crack Resistance | D5397 | Hours | >400 |

Environmental Stress Crack Resistance | D1693 | Hours | 6000 |

Carbon Black Content | D1603 | % | 1.5%-2.0% |

Nominal Sheet Thickness Before Texturing | D5199 | mm | 1.27-5%,+10% |

Nominal Sheet Thickness After Texturing | D5199 | mm | 1.52-5%,+10% |

Strip Puncture Resistance | D4833 | N | 450 |

Seam Peel Strength | EN ISO 13426-18 | N | 1065 1420 2130 2840 |

Seam Efficiency | GRI-GS13 | % | 100 |

Nominal ExpandedCell Size (width *length) | mm | 475*508, 500*500 etc | |

Nominal Expanded Panel Size (width length) | mm | 2.56*8, 4.5*5.0, 6.5*4.5, 6.1 *2.44 |

Product Type | Smooth and Not Perforated | Smooth and Perforated | Textured and Not Perforated | Textured and Perforated |

Height (mm) | 50≤H≤250 | 50≤H≤250 | 50≤H≤250 | 50≤H≤250 |

Welding Distance(mm) | 330≤A≤1000 | 330≤A≤1000 | 330≤A≤1000 | 330≤A≤1000 |

Thickness (mm) | 1.0- 1.2 | 1.0- 1.2 | 1.3- 1.7 | 1.3- 1.7 |

Seam Peel Strength of Welding Point (N/cm) | ≥100 | ≥100 | ≥100 | ≥100 |

Tensile Strength of Connection of Cells (N/cm) | ≥120 | ≥120 | ≥120 | ≥120 |

Tensile Strength at Yield of Each Sheet (N/cm) | ≥200 | ≥200 | ≥200 | ≥200 |

Remarks: Width ofthe productscan be customized according to the customer's requirements.

It is mainly used for

1.foundation reinforcement(ground stabilization:)

2.soft foundation treatment,

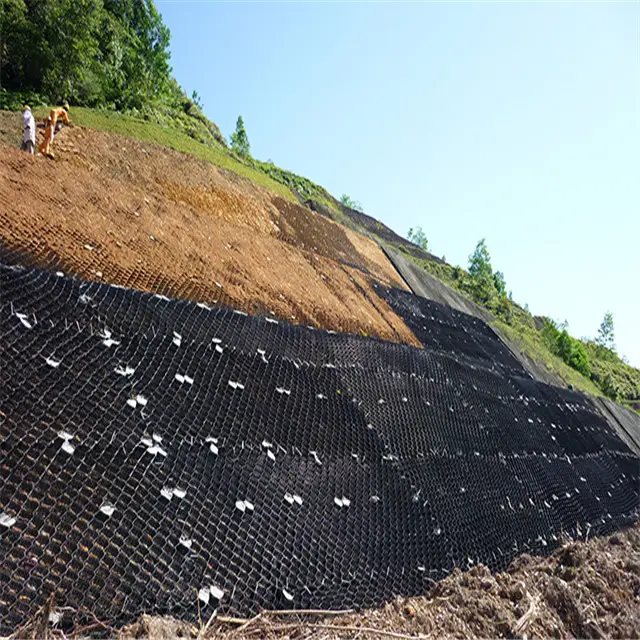

3.steep slope protection,

4.landslide prevention,

5.load-bearing mixed retaining wall.

6.It is especially suitable for weathering forests, sand streams and marshes.

1.foundation reinforcement(ground stabilization:)

2.soft foundation treatment,

3.steep slope protection,

4.landslide prevention,

5.load-bearing mixed retaining wall.

6.It is especially suitable for weathering forests, sand streams and marshes.

Shandong Luyida New Material Co., Ltd is a manufacturing enterprise specializing in the research, production and sales of geosynthetics.We are professional manufacturer of geomembrane, geocell, non woven geotextile, grass grid, geogrid, geotube and so on geosynthetic goods, with nearly 20 production lines in all.It is one of the members of China Geosynthetics Technology Association and Building Waterproof Material Association. We are sparing no efforts to build a world brand of geosynthetic.

As a leading manufacturer of geosynthetics, it has 9 years of export experience and has been unanimously recognized and praised by engineering experts and customers. If you need these products now or in the future, Welcome send inquiry to us!

As a leading manufacturer of geosynthetics, it has 9 years of export experience and has been unanimously recognized and praised by engineering experts and customers. If you need these products now or in the future, Welcome send inquiry to us!

Q1: Are you trading company or manufacturer?

A: We are officially licensed MANUFACTURER specializing in the research, production and sales of geosynthetics with 9 years of export experience.

Q2: How about the quality of your products?

A: We have professional brand machine production line and quality control center.Each batch of products will be sampled before package and there also is a final inspection before shipment.

Q3: Can you provide free sample?

A: Yes, we can offer free samples of some items for quality evaluation.

Q4: Can you accept small order?

A: Yes.

Q5: Do you accept customized design order?

A: Yes.We welcome customized design orders.

Q6: What is your lead time?

A: General within 3-7 days or more(if your order quantity is large).

Q7: What’s your delivery term?

A: We can accept EXW, FOB, CIF, etc( according to the actual country and region).

Q8. What is the payment way?

A: T/T,L/C,D/P D/A,PayPal,Western Union,Online Bank Payment.

If you have any another question,please feel free to contact us at any time.Wish you have a good purchasing experience.

A: We are officially licensed MANUFACTURER specializing in the research, production and sales of geosynthetics with 9 years of export experience.

Q2: How about the quality of your products?

A: We have professional brand machine production line and quality control center.Each batch of products will be sampled before package and there also is a final inspection before shipment.

Q3: Can you provide free sample?

A: Yes, we can offer free samples of some items for quality evaluation.

Q4: Can you accept small order?

A: Yes.

Q5: Do you accept customized design order?

A: Yes.We welcome customized design orders.

Q6: What is your lead time?

A: General within 3-7 days or more(if your order quantity is large).

Q7: What’s your delivery term?

A: We can accept EXW, FOB, CIF, etc( according to the actual country and region).

Q8. What is the payment way?

A: T/T,L/C,D/P D/A,PayPal,Western Union,Online Bank Payment.

If you have any another question,please feel free to contact us at any time.Wish you have a good purchasing experience.

Похожие товары

Пластиковая Подпорная Стена geocell

US $0.56-$11.00

Аксессуары geocell

US $0.15

Полиэтиленовый пластик geocell, цена

US $1.65

Пластиковые болты и гайки

US $0.08-$0.15