Сушилка сжиженного нефтяного газа высокоскоростная Центробежная распылительная сушилка

- Категория: Vacuum Drying Equipment >>>

- Поставщик: Anyang,Gaokang,Medical,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 10472.81 $* | 10996.46 $* |

| Aug-16-2025 | 10384.8 $* | 10903.80 $* |

| Jul-16-2025 | 8712.98 $* | 9148.90 $* |

| Jun-16-2025 | 10208.54 $* | 10718.38 $* |

| May-16-2025 | 8888.87 $* | 9332.31 $* |

| Apr-16-2025 | 10032.61 $* | 10534.80 $* |

| Mar-16-2025 | 9944.29 $* | 10441.59 $* |

| Feb-16-2025 | 9856.82 $* | 10349.82 $* |

| Jan-16-2025 | 9768.13 $* | 10256.81 $* |

Характеристики

LPG spray dryer High-Speed Centrifugal Spray Dryer industrial spray dryer

LPG Large Scale Spray Dryer Milk Powder

Spray atomizer / industrial spray nozzle drying technology is shaping and drying of the most widely used industrial process. Ideal for the solution, emulsion, suspension and paste liquid plastic raw materials generated in the powdery, granular or massive solid products. Therefore, when the particle size distribution of the finished product, residual moisture content, bulk density and particle shape must meet precise standards. Spray drying is a very good process.

Working Principle

The air is filtered and heated into the top of the dryer air distributor, hot air into the spiral evenly into the drying chamber. The material liquid is sprayed into a fine atomized liquid droplet through the high-speed centrifugal nebulizer at the top of the tower body, and can be contacted with the hot air in a very short time and can be dried into finished products. The finished product is continuously discharged from the bottom of the drying tower and the cyclone, and the exhaust gas is drained by the draft fan.

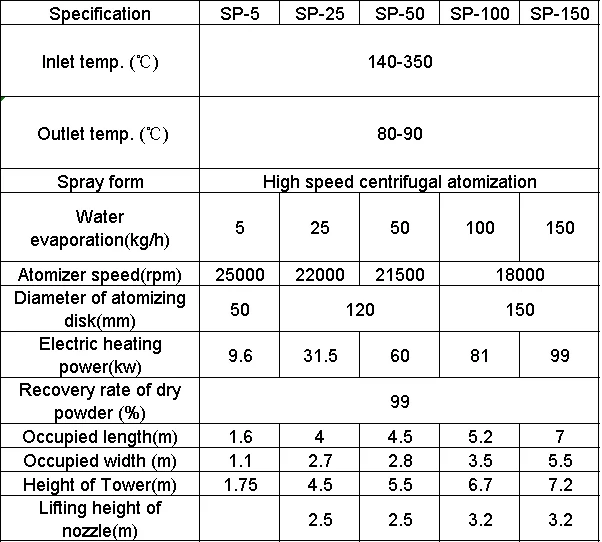

Technical specification

If you have special request ,kindly click here to get your price !

Features

high speed centrifugal spray drying machine

At a high speed of drying, after the spraying of the material liquid, the surface area of the material will be increased greatly. In the hot-air flow, 95%~98% of water can be evaporated at a moment. The time of completing the drying needs only several seconds.

This is especially suitable for drying the heat sensitive materials. Its final products own the good uniformity, mobility, dissolving capacity. And the final products are high in their purity and good in their quality. The production procedures are simple and the operation and control are easy. The liquid with the moisture contents 40~60% (for special materials, the contents may reach 90%.) can be dried into the powder or particle products once a time. After the drying, there is no need for smashing and sorting, so as to reduce the operation procedures in the production and to enhance the product purity. The product particle diameters, looseness and water contents can be adjusted through changing the operation condition in a certain scope. It is very convenient to carry out the control and management.