Промышленный экструдер для завтрака машина закусок производства пищевых кукурузных хлопьев завод по переработке

- Категория: >>>

- Поставщик: Shandong,Sena,Machinery,Technology,Co.,ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.16 $* | 0.93 $* |

| Aug-16-2025 | 0.27 $* | 0.40 $* |

| Jul-16-2025 | 0.49 $* | 0.9 $* |

| Jun-16-2025 | 0.86 $* | 0.93 $* |

| May-16-2025 | 0.64 $* | 0.34 $* |

| Apr-16-2025 | 0.7 $* | 0.88 $* |

| Mar-16-2025 | 0.6 $* | 0.6 $* |

| Feb-16-2025 | 0.75 $* | 0.69 $* |

| Jan-16-2025 | 0.2 $* | 0.82 $* |

Характеристики

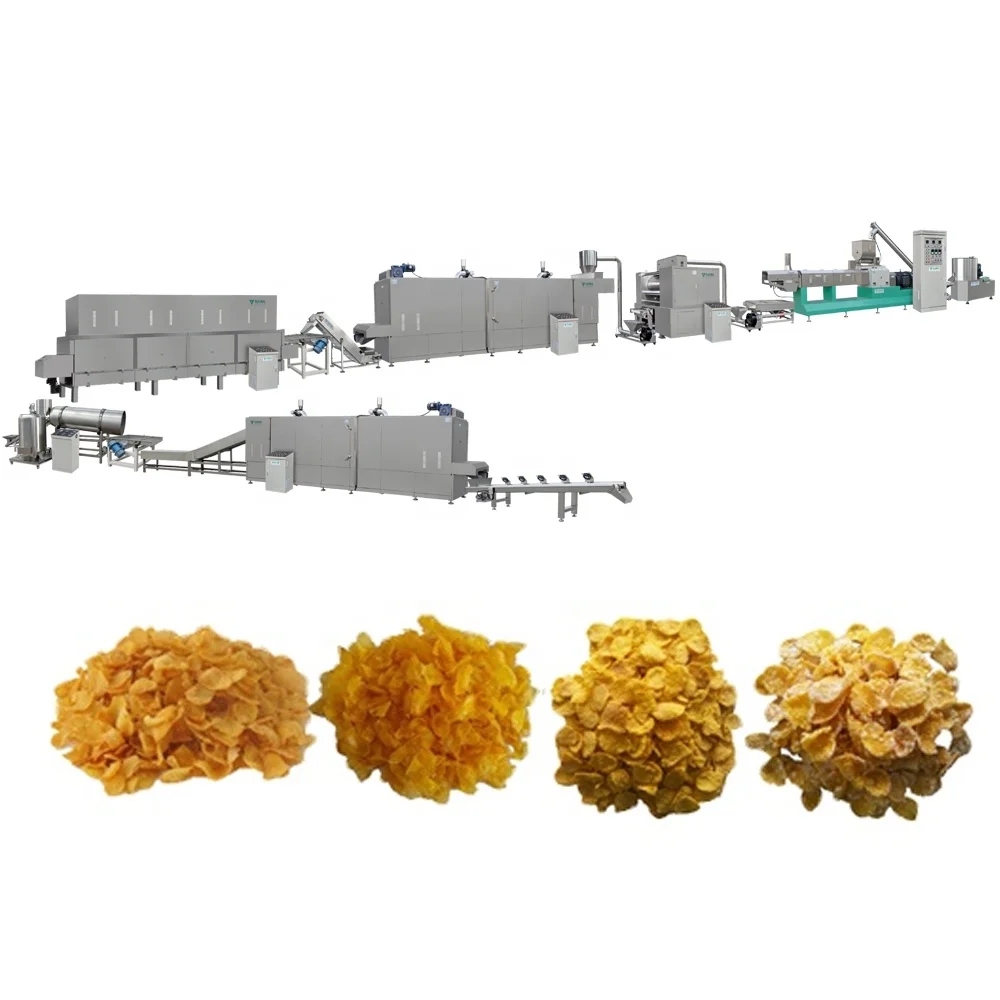

Product display

Breakfast Cereal Extruder Snack Machine Food Snacks Corn Flakes Plant Cereal Processing Line

Breakfast Cereals use corn powder and other cereals as main material, through mixing, extruding, flaking, drying, baking, coating and cooling, to get crispy flakes. It always service as breakfast cereal mixed with milk. This production system can also make other shapes of cereal such as rings, balls, curls etc.

Name | Description of breakfast cereals corn flakes machine |

Raw material | Corn flour, rice flour, wheat flour and other barley powder |

Basic Recipe | Grist powder, sugar, coco powder, water etc |

Processing Flow | mixing system; Extrusion System; Flaking system; Drying system; Coating system; Drying system; cooling system; packing system |

Final products | Breakfast cereals with Variety shapes are available, such as ball, stick, ring, fruit loop, star wheel, flower and heart by adjustable the moulds on the extruder. Natural corn flakes; Sugar coated corn flakes. |

Details Images

Twin Screw Extruder.

It consists of feeding system, extruding system, cutting system, heating system, controlling system and cooling system.

Barrel adopts ray stainless steel heating circles to heat.

Adopt import original bearing with strong capacity.

screw can be assembled freely according to different material and products.

Corn flakes flaking machine.

The key machine of corn flakes production. This machine works automatically. The gap between that two rollers is adjustable, which ensures the thickness of the final corn flakes.

This machine is equipped with water cooling system.

The material of the roller is cast iron, the shaft is 45# steel, machine frame is carbon steel.

The capacity ranges from 100kg/hr to 400kg/hr.

Dryer machine for corn flakes.

The heating source for this dryer can be electric, gas or steam.

The material is stainless steel 304 or can be customized.

This dryer machine consists of rack system, combustion system, de-humidifier system, insulation system and controlling system.

after flaking, it helps to remove the moisture on the surface of corn flakes.

Hot air roaster machine for corn flakes production

The temperature of this hot air roaster can up to 400 C, which is important for the final flavor of corn flakes. To produce crispy corn flakes.

The heating source can be electric or gas.

Hot air is sprayed by high pressure blower, which makes corn flakes puffed and bubbles instantly.

The capacity ranges from 100kg/hr to 400kg/hr.

Dryer machine with cooling part.

Heating method: electric, gas

Layers: three, Five and seven

The speed of mesh belt and drying time is adjustable.

Capacity: 100-500kg/hr

Dryer is compact, it features with high thermal efficiency and heat elimination.

After sugar coating, this dryer will dry the moisture of sugar coated corn flakes.

Before packing, the coated corn flakes will be cooled. If you don't produce sugar coated corn flakes, then this machine is not needed.

Combination head weigher Vertical automatic packing machine .

we have model 420, 520, 620 and 720 vertical packing machine.

Which is chosen according to the weight of your packing bags and shape.

Together with packing machine, air compressor, nitrogen system is also optional according to your basic requirements.

Sample Display

Corn flakes, and variety shapes of breakfast cereals are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart shape by adjusting the mould ion the Extruder.

Product Paramenters

Model | SN70 Corn flakes making machine | SN85 Corn flakes making machine |

Installed power | 205kw | 235kw |

Power consumption | 156kw | 178kw |

Capacity | 200-260kg/hr | 300-400kg/hr |

Dimension | 49000 x 1300 x 2500mm | 50000 x 1300 x 2800 mm |

Flow chart

Sugar coated corn flakes manufacturing plant.

This corn flakes processing line consists of mixer, screw elevator, twin screw Extruder, vibrator, flaking machine, air conveyor, dryer, elevator, hot air roaster, sugar coated system, dryer with cooler and packing machine.

This processing line can also produce breakfast cereals and natural corn flakes by choosing several machines of this corn flakes processing line.

Company Information

SENA Machinery Technology Co., Ltd is located in Jinan city, China. Covering an area of 20000㎡, SENA

company has been a high-tech enterprise with an integration of scientific research, manufacturing and sales. As a professional manufacturer of extruded food equipment, SENA company can supply one-stop solution for extruded food processing industry. Also we can customize our machine to meet customers’ different requirements. Our extrusion system is widely used in puffed leisure food,

cereals, polymer plant protein meat food, pet food, modified starch and so on.

SENA company always adhering to the "compete in science and technology, accept the innovation" purpose and keep the principle of "develop with the customers together". Our company have excellent quality and perfect service, and we treat the views and needs of customers, as a basis for the development and improvement of products, in order to achieve the real solution to customer satisfaction.

SENA company has big sales in domestic market, and also have expanded to the international market. The products have been sold all over the world, ,such as Europe, the United States, Africa, Southeast Asia etc. SENA company will continue to strive for innovation to catch up with the development of food industry

company has been a high-tech enterprise with an integration of scientific research, manufacturing and sales. As a professional manufacturer of extruded food equipment, SENA company can supply one-stop solution for extruded food processing industry. Also we can customize our machine to meet customers’ different requirements. Our extrusion system is widely used in puffed leisure food,

cereals, polymer plant protein meat food, pet food, modified starch and so on.

SENA company always adhering to the "compete in science and technology, accept the innovation" purpose and keep the principle of "develop with the customers together". Our company have excellent quality and perfect service, and we treat the views and needs of customers, as a basis for the development and improvement of products, in order to achieve the real solution to customer satisfaction.

SENA company has big sales in domestic market, and also have expanded to the international market. The products have been sold all over the world, ,such as Europe, the United States, Africa, Southeast Asia etc. SENA company will continue to strive for innovation to catch up with the development of food industry

Packing & Shipping

Corn flakes production line packing .

Plastic bubble film on the surface of breakfast cereals corn flakes manufacturing plant, wooden case for the spare parts of corn flakes line machinery. Or as your request.

FAQ

1. Could we visit your factory to check the machine carefully and closely?

You’re more than welcome to visit SENA, will provide machine test running, face to face discussion and turnkey project design solution.

2. Could you afford technician team to guide our installation and commissioning?

Oversea commissioning service provided, our technician will help to install the machine, and teach local workers about operation and maintenance. Buyer should pay for the technician's round flight ticket, accommodation and salary.

3. How long is your machine's guarantee time?

One year since the machine arrive your factory.

4. If some parts break after warranty, what should we do?

SENA supply full-life after sales service, whenever new parts needed, we will help to supply new ones at reasonable price & in shortest time.

5. If we show our workshop size, can you design layout for the whole line?

Auto CAD layout will be provided as client’s workshop size.

6. What is the material of the machine?

Stainless steel, especially parts contacting with materials, conforming to food grade.

You’re more than welcome to visit SENA, will provide machine test running, face to face discussion and turnkey project design solution.

2. Could you afford technician team to guide our installation and commissioning?

Oversea commissioning service provided, our technician will help to install the machine, and teach local workers about operation and maintenance. Buyer should pay for the technician's round flight ticket, accommodation and salary.

3. How long is your machine's guarantee time?

One year since the machine arrive your factory.

4. If some parts break after warranty, what should we do?

SENA supply full-life after sales service, whenever new parts needed, we will help to supply new ones at reasonable price & in shortest time.

5. If we show our workshop size, can you design layout for the whole line?

Auto CAD layout will be provided as client’s workshop size.

6. What is the material of the machine?

Stainless steel, especially parts contacting with materials, conforming to food grade.