ZONTAI высокоскоростная разрезающая и перематывающая машина (ZTM-D) перемотка 400 м/мин производственная мощность

- Категория: Оборудование для производства бумаги >>>

- Поставщик: Ruian,Xincheng,Zhongtai,Packaging,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.68 $* | 0.65 $* |

| Aug-15-2025 | 0.82 $* | 0.30 $* |

| Jul-15-2025 | 0.92 $* | 0.27 $* |

| Jun-15-2025 | 0.69 $* | 0.12 $* |

| May-15-2025 | 0.61 $* | 0.83 $* |

| Apr-15-2025 | 0.3 $* | 0.34 $* |

| Mar-15-2025 | 0.4 $* | 0.74 $* |

| Feb-15-2025 | 0.30 $* | 0.20 $* |

| Jan-15-2025 | 0.1 $* | 0.13 $* |

Характеристики

Product Information

The machine applies to slit cellophane, PET, OPP, CPP, PE, PS, PVC and computer security labels,Meltblown Non-woven

, optical materials, film roll, foil roll, all kinds of paper rolls, film and printing of various

materials.,etc

, optical materials, film roll, foil roll, all kinds of paper rolls, film and printing of various

materials.,etc

Jumbo roll width | 1000mm-1600mm |

Diameter of roll | Ø800mm |

Diameter of rewinding | Ø600mm |

Inner diameter of paper core | 3’’or 76mm(optional:6’’or 152mm) |

Slitting speed | 10-450/min |

Tolerance of EPC | ≤0.1mm |

Min.width of produce | 50mm |

Total power | 12KW |

Weight | 4500Kg |

overall dimension (L X W X H) | 2000mm x 4200mm x 1840mm |

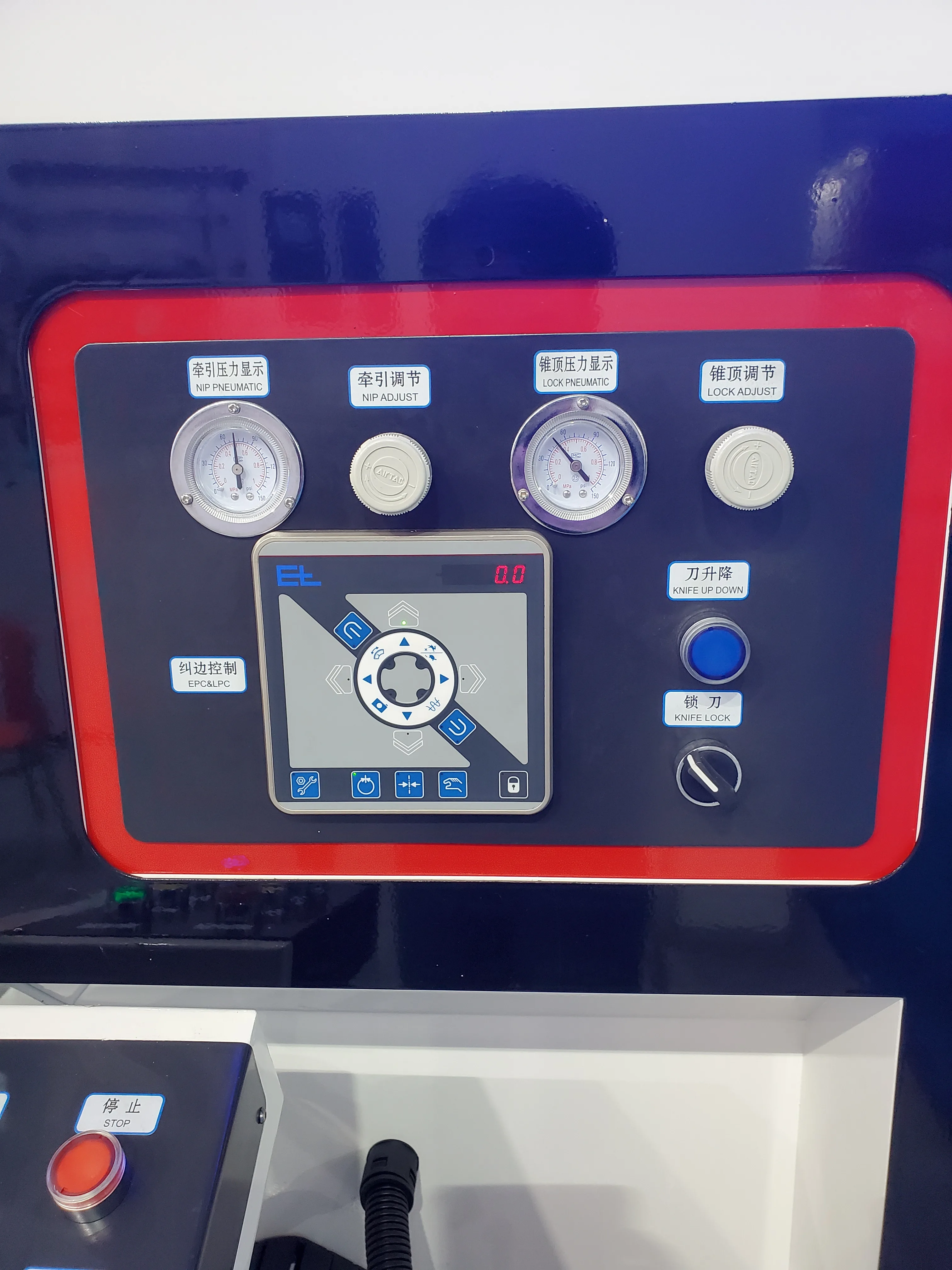

1, Unwinding unit: it shaftless auto loader, which is caught taking raw materials fast, easy loading, single-person operation. EPC (Edge position control) uses imported LPC corrective device, it can achieve guide function by material edge and printed marks.

Unwinding tension adopts magnetic powder brake through PLC to achieve a constant tension.

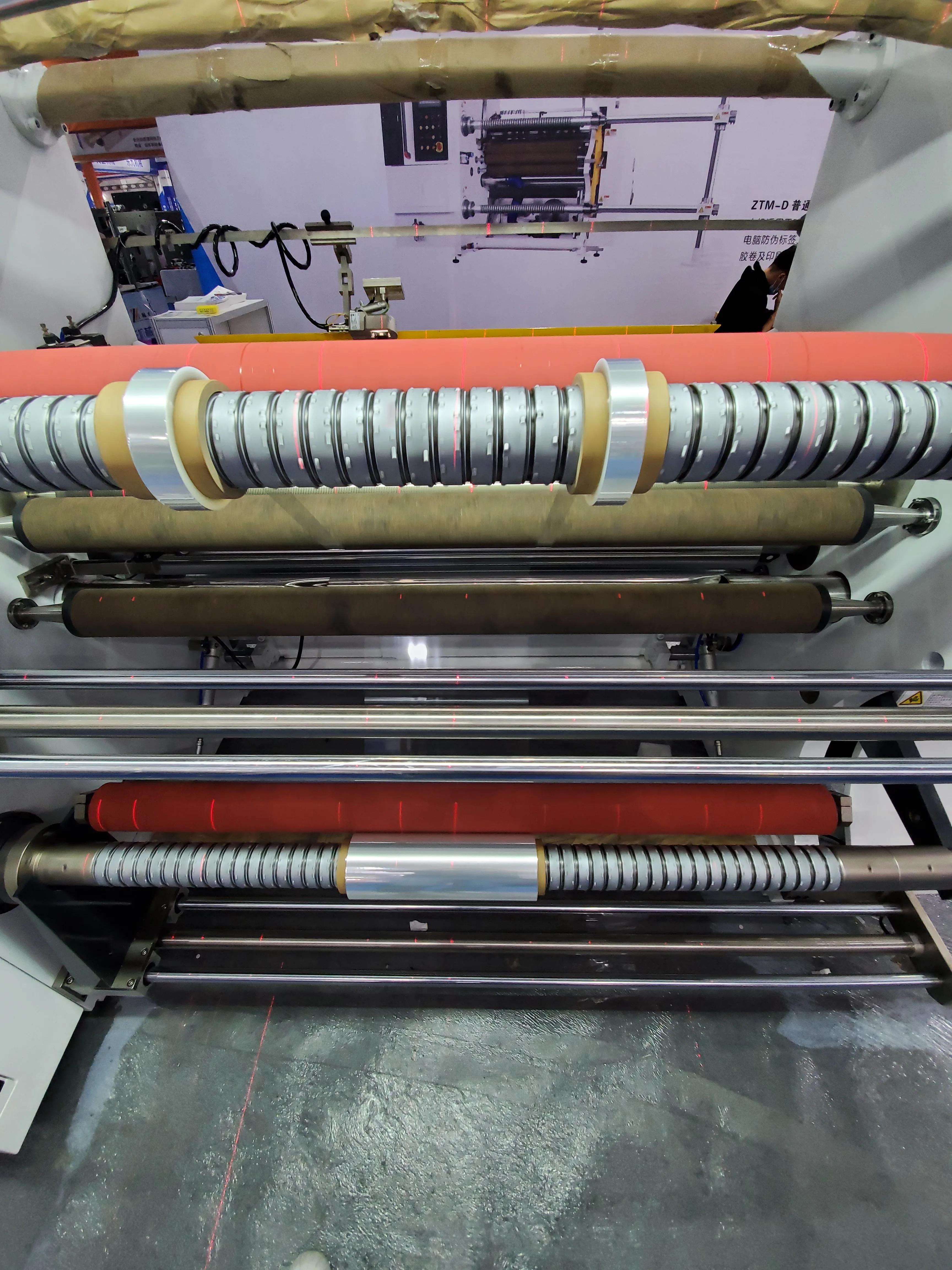

2, Slitting Unit: This machine equipped with two kinds of slitting method: Flat knife slit and circular knife slit.

3, Rewinding Unit: rewinder parts uses 2pcs of pneumatic friction shafts.

4, winding sticks pressure unit : The machine is equipped with two sets of pneumatic pressure automatic lifting sticks, tension automatic control by computer.

5, waste edge processing section: This model is equipped with a vacuum-type waste edge exclusion system, use the strong force adsorb the waste edge out away

6, Electrostatic elimination Unit: The machine equipped a group of static brush before rewinding shaft , which can effectively eliminate the static between slitting and rewinding .

7, Finished Produce unloading Unit :

It is a discharge rack can provide a larger diameter of the finished product is simple and efficient to operate and save time for the next feed.

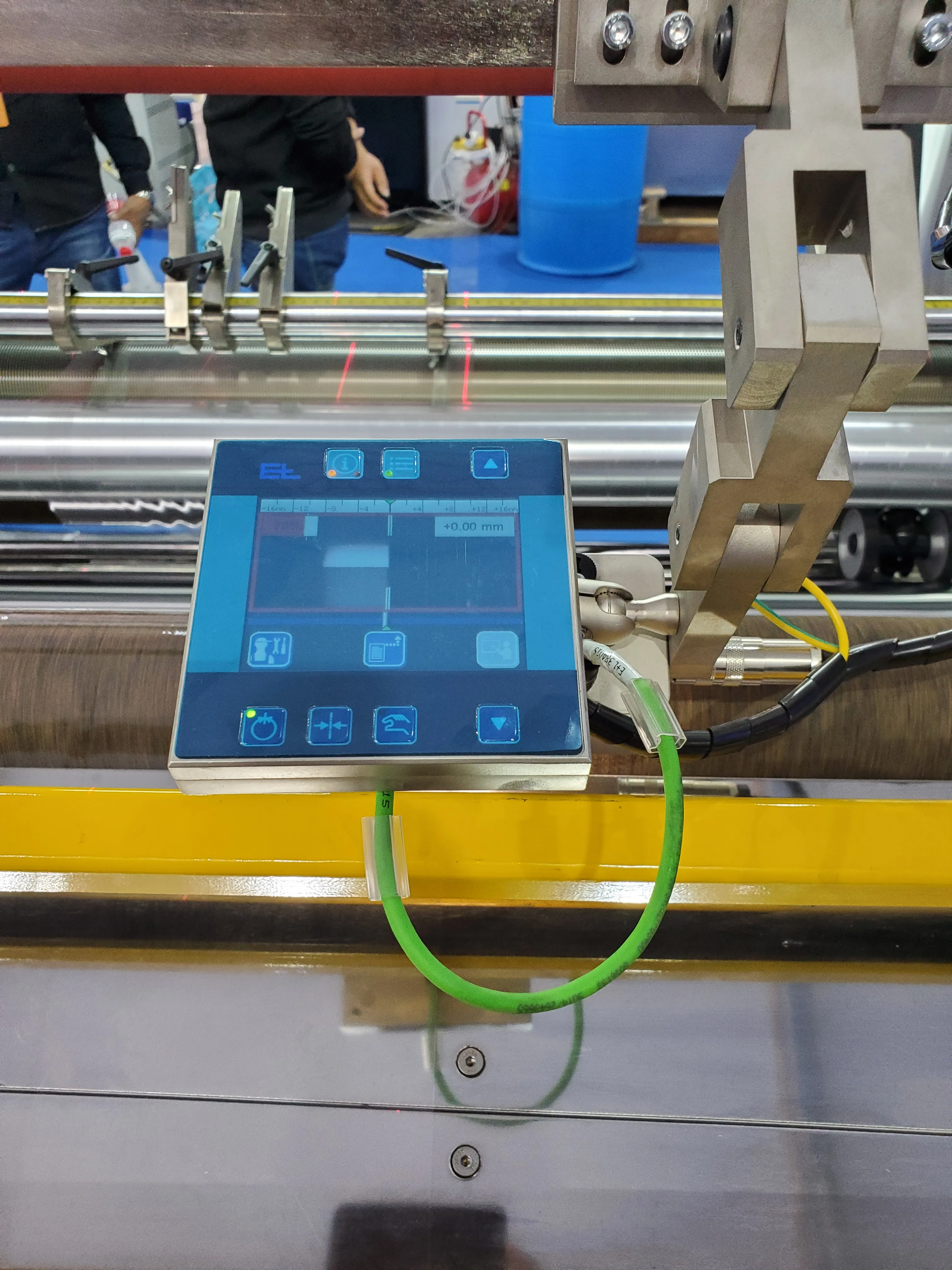

8, PLC control system: Adopt imported PLC to achieve accurate and stable control, true color touch screen display to enable simple and beautiful images. Interactive parameter setting the environment, eliminating the complicated configuration can start the job: The user pre-start only need to input the material thickness, width, density, diameter and speed parameters, the next will be done automatically by a computer calculation to complete.

Unwinding tension adopts magnetic powder brake through PLC to achieve a constant tension.

2, Slitting Unit: This machine equipped with two kinds of slitting method: Flat knife slit and circular knife slit.

3, Rewinding Unit: rewinder parts uses 2pcs of pneumatic friction shafts.

4, winding sticks pressure unit : The machine is equipped with two sets of pneumatic pressure automatic lifting sticks, tension automatic control by computer.

5, waste edge processing section: This model is equipped with a vacuum-type waste edge exclusion system, use the strong force adsorb the waste edge out away

6, Electrostatic elimination Unit: The machine equipped a group of static brush before rewinding shaft , which can effectively eliminate the static between slitting and rewinding .

7, Finished Produce unloading Unit :

It is a discharge rack can provide a larger diameter of the finished product is simple and efficient to operate and save time for the next feed.

8, PLC control system: Adopt imported PLC to achieve accurate and stable control, true color touch screen display to enable simple and beautiful images. Interactive parameter setting the environment, eliminating the complicated configuration can start the job: The user pre-start only need to input the material thickness, width, density, diameter and speed parameters, the next will be done automatically by a computer calculation to complete.

Company Profile

Exhibition

FAQ

Product packaging

Choose Us