Автоматический дезинфицирующий инструмент Newcrown с 4 полосами машина для выдувного формования спиртовых

- Категория: Stretch Blow Moulding Machines >>>

- Поставщик: Zhangjiagang,City,New,Crown,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 89250.69 $* | 93713.8 $* |

| Aug-15-2025 | 88500.15 $* | 92925.25 $* |

| Jul-15-2025 | 74250.86 $* | 77963.87 $* |

| Jun-15-2025 | 87000.68 $* | 91350.5 $* |

| May-15-2025 | 75750.68 $* | 79538.82 $* |

| Apr-15-2025 | 85500.82 $* | 89775.54 $* |

| Mar-15-2025 | 84750.5 $* | 88988.9 $* |

| Feb-15-2025 | 84000.98 $* | 88200.11 $* |

| Jan-15-2025 | 83250.63 $* | 87413.15 $* |

Характеристики

Zhangjiagang City New Crown Machinery is specialized in manufacturing two–step high speed automatic linear blow molding machines which are applicable in a wide range of PET packaging practice, such as for beverages, edible oil, food, pharmaceutical products and cosmetics,etc. With more than 10 years experience in developing and producing blow molding machine as well as the advanced technology absorbed domestic and abroad, we have developed with our constant innovation dozens of high speed and high precision equipments which have won the top reputation in the filed.

Technology innovation is our eternal tenet. Continuous improvement and genuine professionalization are what we have been chasing while extreme precision,top quality and high capacity are what we live upon. Meanwhile,we are to satisfy the customers with perfect after-sales service. Looking to variety, high tech, high speed and high efficiency is the way by which we are developing.

The normative quality monitoring system plays a key role for our products to gain customers and occupy a position in the market. We have established the data analysis and tracking system for those critical parts and components, such as the electrical, hydraulic , pneumatic components, servo motors and so on, most of which are products of the top brands in the world whose excellent quality ensures the long lifetime and good performance of the parts. Making quality machines has been the primary working principle of every staff of New Crown.

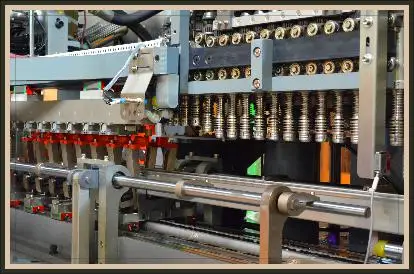

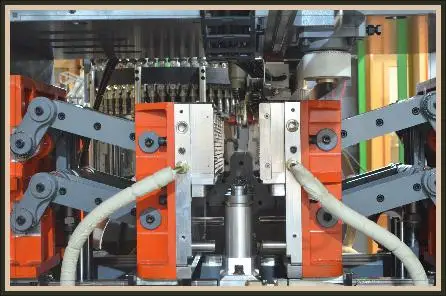

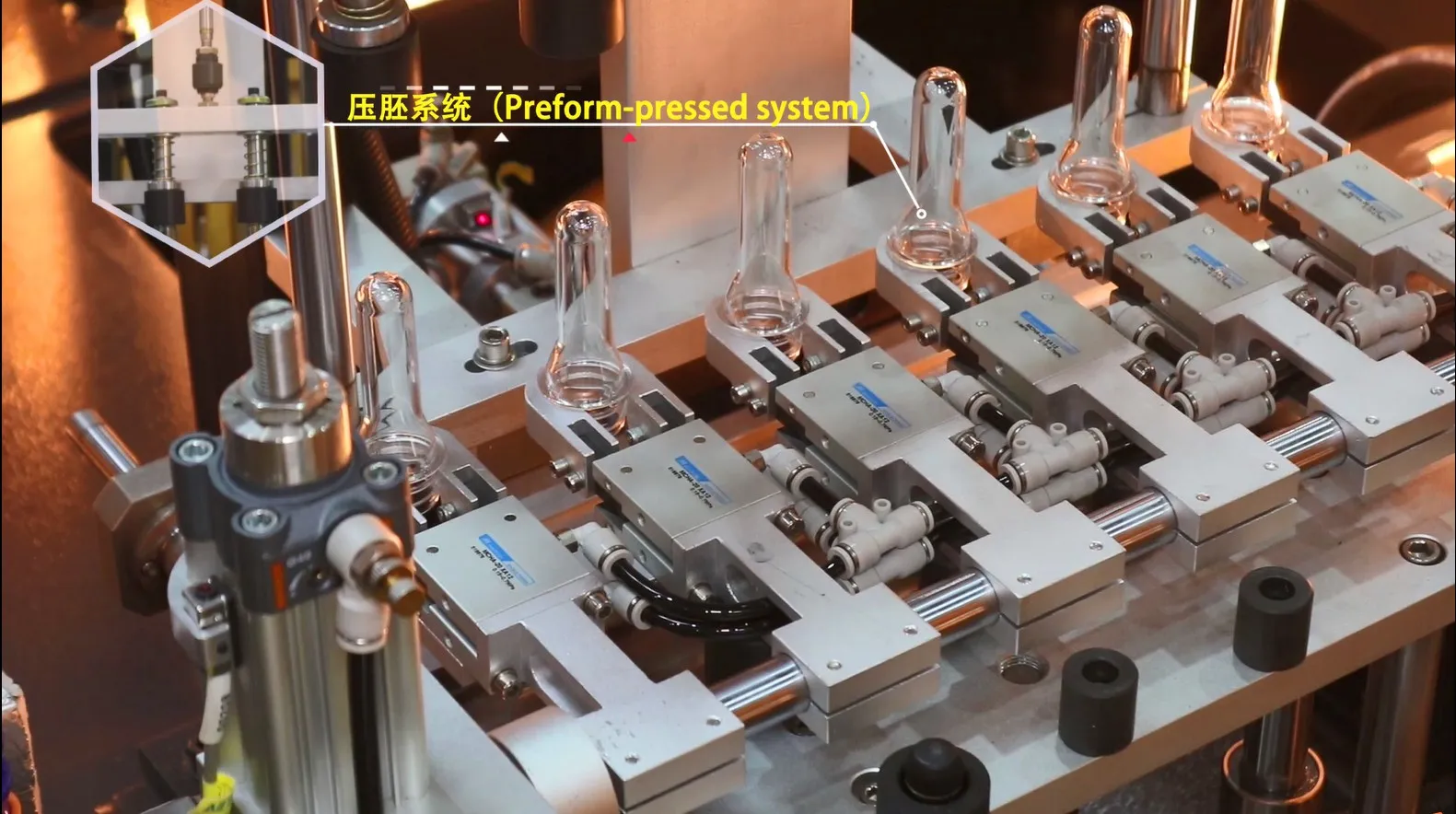

1,The machine use continuous rotation system with multiple safety protection devices to ensure the high speed preform feeding

2,Horizontal rotation transfer system make the construction and maintance more easy, reduce cost of spare part change.

3,Compact preform heating distance design for efficient heating and reduce energy consumption 4,The water runs directly through the heating channel with air cooling system to protect protect

preform neck from deformation

5,Optimize oven air draft and preform surface cooling. Reversible heating box make it more easy to change lamp.

6,Mould closing adopts CAM linkage, no chain plate pin shaft make it small volume and long lift

7,Using hard claw to catch the preform and bottle, nowear with long life.

8,Servo motor for moving the preform into mould, ensure fast speed and accurate positioning.

9,Servo moto is used to drive the drawing and blowing station, equipped with high speed precision blowing valve set to achieve high production requirements.

| Blow Molding Machine | ||||

| Model |

2 cavity |

4 cavity |

6 cavity |

9 cavity |

| ProductionB/H(600ml) | 3000-4000 | 6000-7000 | 9000-10000 | 12000 |

| Bottle standard | Neck:φ50-100mmHeight150-320mm | |||

| Mold middle pitch | 76mm | |||

| HP air compressure | 3m3/min40kg | 4m3/min 40kg | 6m3/min 40kg | 8m3/min 40kg |

| Water Chiller | 3HP | 3HP | 5HP | 8HP |