Плавающее оборудование для переработки корма рыбы машина производства

- Категория: Pet Food Processing Machines >>>

- Поставщик: Shandong,Joyang,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 23800.62 $* | 24990.48 $* |

| Aug-18-2025 | 23600.79 $* | 24780.14 $* |

| Jul-18-2025 | 19800.30 $* | 20790.8 $* |

| Jun-18-2025 | 23200.33 $* | 24360.71 $* |

| May-18-2025 | 20200.97 $* | 21210.80 $* |

| Apr-18-2025 | 22800.49 $* | 23940.25 $* |

| Mar-18-2025 | 22600.55 $* | 23730.74 $* |

| Feb-18-2025 | 22400.96 $* | 23520.38 $* |

| Jan-18-2025 | 22200.34 $* | 23310.49 $* |

Характеристики

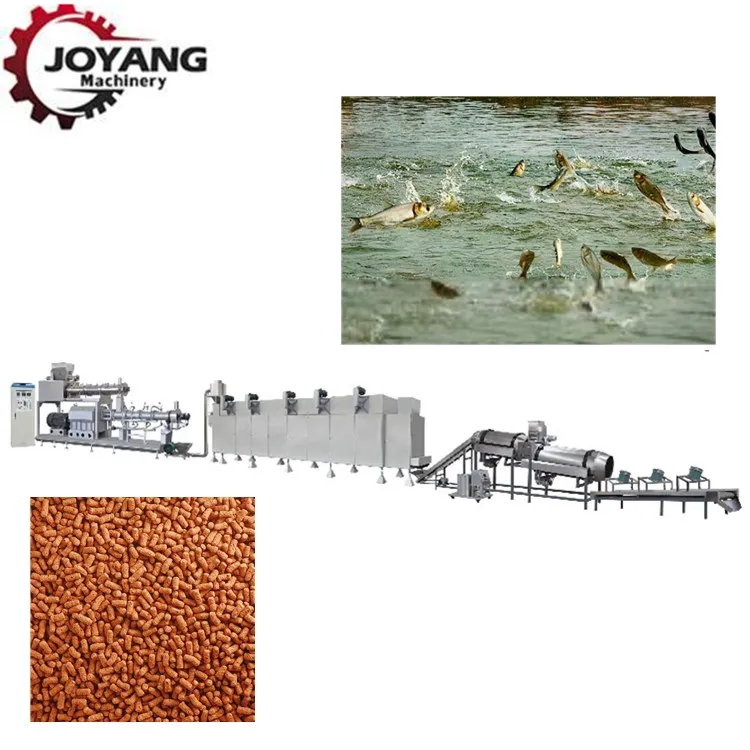

Floating Fish Feed Processing Equipment Animal Feed Making Machine Fish Food Machinery

Raw materials:

This line adopts bone powder, fish meal, corn powder and so on as raw materials.

Final products:

The production line can produce the different pellets of fish feed from 1mm to 18mm.

In addition, changing the moulds and process technology, you can produce various shapes of pet food for cat, dog, shrimp, bird and so on.

The final feed is nutritional, multi-shape, attractive, highly digestible which can be loved by your pet and fish.

Flow chart:

Mixer ---Screw conveyor--- Twin-screw extruder--- air conveyor--- Dryer--- Hoister---Roller--- Cooling conveyor

140-160kg/h, 240-260kg/h Fish Feed Production Line

500-1000kg/h Fish Feed Production Line

Technical Parameter:

| Model | Capacity | Installed Power | Power Consumption | Dimension |

| JY65 | 140-160kg/h | 76kw | 53kw | 17x2x2.5m |

| JY70 | 240-260kg/h | 105kw | 75kw | 22x2x2.5m |

| JY85 | 500kg/h | 178kw | 125kw | 26x2x3.5m |

| JY90 | 1000-1200kg/h | 215kw | 165kw | 40x2.4x4m |

Features:

1. Flexible collocation;

2. Extensive applied raw materials;

3. Various snacks;

4. Easy operation.

Twin-screw extruder

It can produce different size of fish feed by changing the mould.

Dryer

It is used to remove the moisture.

The temp of the dryer and the drying time can both be controlled which can make sure that the food will be fully dried.

It can take electricity, gas, diesel, steam as main energy.

Packing:

inside plastic bag,

outside wooden case (Based on the customers' need adopt the wooden case or wooden pellets, etc.).

Transportation:

Shipping, train, express or upon clients' demands.

We will provide the most thoughtful services for our clients:

Before sales service

1. Free consultation service before, during, and after sales;

2. Free Project planning and design services upon clients' special demands;

3. Debugging and inspecting of equipment until everything is functional before leaving the factory;

During sales service

Management of equipments' long distance shipping from seller's factory to the named place by buyer;

After sales service

1. Training of equipment maintenance and operating personally;

2. New production techniques and formulas;

3. Provide 1 year complete warranty and life-time maintenance service.

Shandong Joyang Machinery Co., Ltd. is a professional supplier of food processing machines. Our company's Motto is: "Service and quality are equally important". We offer to cooperate with our customers for mutual and beneficial development. All Inquiries are welcome.

Our main products line include puffed snacks production line, core filling snack production, corn flakes/ breakfast cereals production line, pasta / pellet chips production line, kurkure production line, artificial rice production line, pet food production line, etc Most importantly, we also provide formulas, technology supports, machine inspection service, etc.

We have a group of experienced experts and outstanding engineers who do provide the professional service delivery and installation. Based on the clients specific relationships, we also design and produce the machines to order. We have through the years established good working relationships with some reputable organizations both at home and abroad with outstanding goodwill.

Contact with us