Сварочный аппарат для бетонных

- Категория: Other Welding Equipment >>>

- Поставщик: Baoshengcheng,New,Energy,Technology,Tangshan,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 13090.10 $* | 13745.95 $* |

| Aug-16-2025 | 12980.67 $* | 13629.47 $* |

| Jul-16-2025 | 10890.1 $* | 11435.50 $* |

| Jun-16-2025 | 12760.69 $* | 13398.96 $* |

| May-16-2025 | 11110.81 $* | 11666.29 $* |

| Apr-16-2025 | 12540.85 $* | 13167.62 $* |

| Mar-16-2025 | 12430.56 $* | 13052.78 $* |

| Feb-16-2025 | 12320.80 $* | 12936.52 $* |

| Jan-16-2025 | 12210.55 $* | 12821.87 $* |

Характеристики

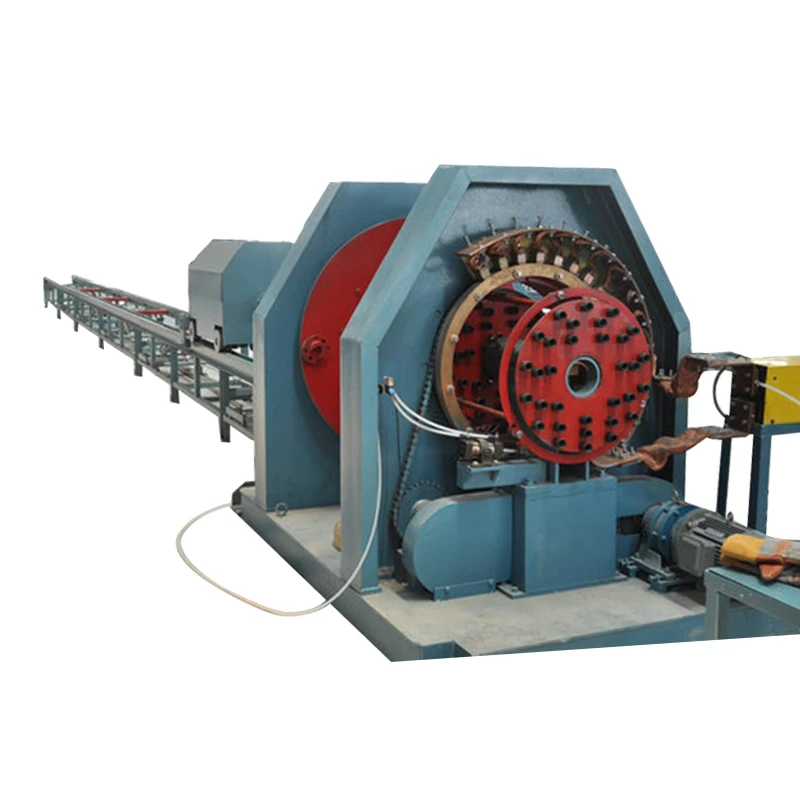

Description | Fully automatic pipe pile steel frame roll welding machine | ||||||

Fully automatic | Yes | ||||||

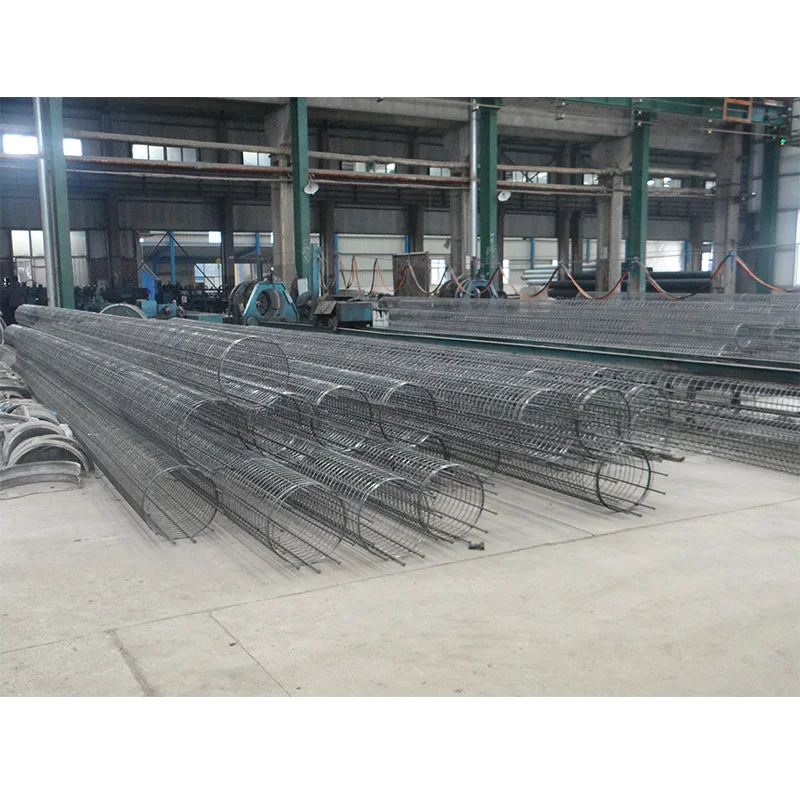

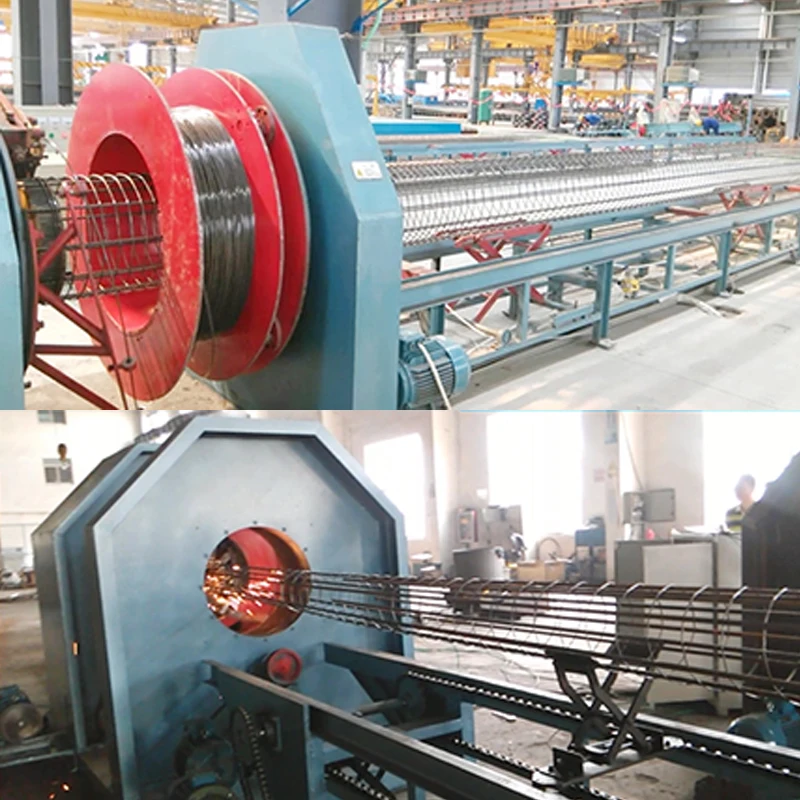

Production specifications | φ300-φ600 mm,φ500-φ800 mm,φ800-φ1200 mm | ||||||

Skeleton length | 0~15m,0~26m | ||||||

Welding power | DC 300KVA 、AC 300 KVA | ||||||

Longitudinal rebar diameter | φ7.1~φ12.6 mm | ||||||

Host speed | DC≤75 R.P.M 、 AC≤70 R.P.M | ||||||

Remark | We will give away more consumable parts such as welding electrode plates. | ||||||

Product performance and advantages: | ||||||||

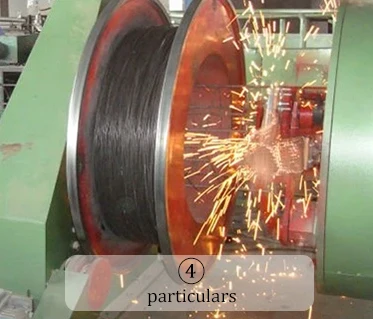

1 When the roll welding machine is working, the electrode plate is at a certain angle with the vertical direction. | ||||||||

(1) Optimized the force direction of the electrode | ||||||||

(2) Shortened the friction distance between the steel bar and the electrode | ||||||||

(3) Eliminates the possibility of shunting the front and rear solder joints, further improving the welding speed | ||||||||

2 The movement trajectory of the welding electrode and the conductive electrode changed from the past parallel movement to the rotation. | ||||||||

(1) Alleviating the distortion of the longitudinal reinforcement caused by the welding electrode's friction on the longitudinal reinforcement | ||||||||

(2) Prolong the service life of the welding electrode plate. | ||||||||

3 Change the fixing method of the welding electrode plate and the conductive electrode plate. | ||||||||

(1) The machine is fixed by press-fitting, which solves the problems of bolt damage caused by overheating or bolt conductivity caused by the working process of bolt connection. | ||||||||

(2) It is more convenient to replace the welding electrode plate and the conductive electrode plate, and it can be used once again after the wear and tear. | ||||||||

Q:Do you have set up an independent factory?

A:We have our own factory. Has the specialized cement machinery product equipment factory, also has the large-scale cement drain pipe production factory.

Q:What can you do for us?

A:1. Before sales can be targeted to give some constructive Suggestions.

2.Make a specific plan for your needs.

3. After sales reference specific products, different products have different services. Refer to the specific product description.

Q: Can you do the basic design for us?

A: Yes, we have a professional team with rich experience in basic design of cement pipe making equipment with CAD software. You just need to tell us your ideas and requirements, and we will provide you with the most perfect design.

Yes, we have a very large engineering installation team that can train and instruct your workers to operate the installation equipment.

We provide customized services as long as you provide the appropriate drawings and product requirements.

Our delivery time varies according to the quantity of the order, usually around 30 days.

We warmly welcome you to visit our factory! We look forward to building successful business relationships with new customers around the world in the future.