Высокая производительность PZ-3 торкретирования/бетона машина для горячего распыления 3m3/ч сухой Mix

- Категория: Shotcrete Machine >>>

- Поставщик: Zhengzhou,Pioneer,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.91 $* | 0.77 $* |

| Aug-16-2025 | 0.59 $* | 0.47 $* |

| Jul-16-2025 | 0.3 $* | 0.7 $* |

| Jun-16-2025 | 0.96 $* | 0.19 $* |

| May-16-2025 | 0.33 $* | 0.83 $* |

| Apr-16-2025 | 0.94 $* | 0.7 $* |

| Mar-16-2025 | 0.5 $* | 0.37 $* |

| Feb-16-2025 | 0.68 $* | 0.45 $* |

| Jan-16-2025 | 0.67 $* | 0.85 $* |

Характеристики

PZ-3 dry mix gunite machine

| Output Capacity | 3m3 /h |

| Max. Horizontal Conveying Distance | 200m |

| Suitable Mix Ratio(Cement/Sand) | ≤0.4 |

| Max. Aggregate Size | Φ10 mm |

| Conveying Hose Inner Diameter | Φ42 /Φ51 mm |

| Conveying Pressure | 0.2-0.6MPa(29-58PSI) |

| Air Consumption | 5-6m3/min |

| Filling Height | 1.1m |

| Rotor Speed | 13.2 RPM |

| Motor Type | Motor Type |

| Power | 3kW |

| Overall Dimension(LxWxH) | 1.13×0.54×1.02m |

| Net Weight | 430kg |

Application

PZ-3 Shotcrete/concrete spraying Machine is mainly used for dry-mix shotcreting and damp-mix shotcreting. It has some obvious advantages such as advanced technology, Perfect structure, stable performance, convenient operation and longevity of service etc. It is widely employed in mining, tunnel, culvert, subway, hydropower engineering, underground excavation engineering etc.

Machine Structure and Working Theory

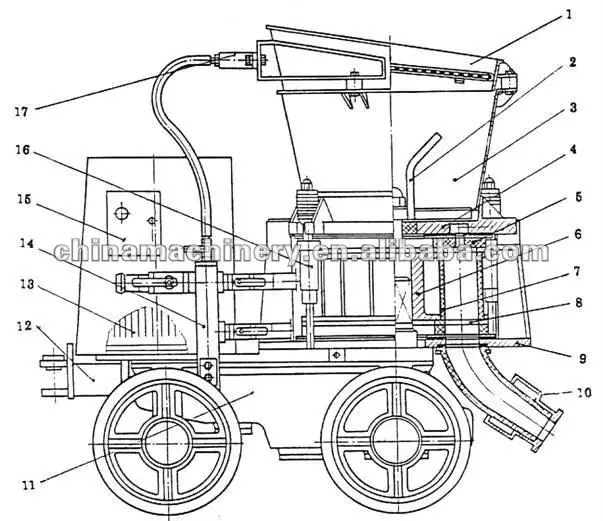

PZ-3 Shotcrete Machine mainly includes drive device, rotor assy., air conveying system, spraying system and electric control casing etc.

PZ-3 Shotcrete System

1. Vibrating Hopper 2. Agitator Paddle 3. Hopper 4.Hopper Bottom

5. Sealing Plate 6. Rotor Body 7.Rubber Chamber 8. Rotor Disk

9. Face Plate 10. Vortex Stream Implement 11.Gear-box 12.bottom Frame

13. Electric Motor 14. Air Pipe System 15.Electric Control Casing

16. Clamping Device 17.Vibrator

4.Machine Structure and Working Theory

The structure and working theory of PZ-3 dry mix gunite machine is shown as figure 1. The premixed materials are filled into vibrating hopper 1, and then passing through vibrating sieve to hopper 3. From there it flows into the through-going chambers of rotor 7 by the action of agitator 2 and moves to the discharge outlet with rotor running, where it is blown to Vortex Stream Implement 10 by compressed air leaded by air pipe 14. Here it is blown by scattering, accelerating, whirling, and floating vortex stream and through conveying hose to the nozzle, where a little adjustable amount water (for damp-mix shotcreting) is added.

If you have any other questions,please contact us!

Q: How long is your delivery time?

A: Generally it is 3-5days if the machines are in stock. It is 5-7 days if not in stock, it is according to quantity.

Q: Do you offer sample?

A: We could offer the sample in cheaper price but exclude the freight.

Q: The operating interface is in Chinese or English?

A: Normal, our tapping machine is Chinese-English switching interface, we also can make All-English type according to the customer's request.

Q: Taps are included in the package?

A: Taps are excluded in our package.we can equip chucks according our customers' requirements.

Q: What kind of chucks are included in your package?

A: We have three types: ISO/JIS/DIN type in stock, you can chose one type from the three. If there is no special requirements, we will send ISO chuck.

Q: Product warranty?

A: 12 months after payment. If there is no special requirements, we will send ISO chuck.