Машина для жевания закусок домашних животных по хорошей цене линия переработки пищевых продуктов сделано в

- Категория: Pet Food Processing Machines >>>

- Поставщик: Shandong,Loyal,Intelligent,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.37 $* | 0.54 $* |

| Aug-15-2025 | 0.53 $* | 0.92 $* |

| Jul-15-2025 | 0.93 $* | 0.67 $* |

| Jun-15-2025 | 0.5 $* | 0.89 $* |

| May-15-2025 | 0.34 $* | 0.76 $* |

| Apr-15-2025 | 0.30 $* | 0.26 $* |

| Mar-15-2025 | 0.89 $* | 0.65 $* |

| Feb-15-2025 | 0.25 $* | 0.74 $* |

| Jan-15-2025 | 0.3 $* | 0.94 $* |

Характеристики

Product Description

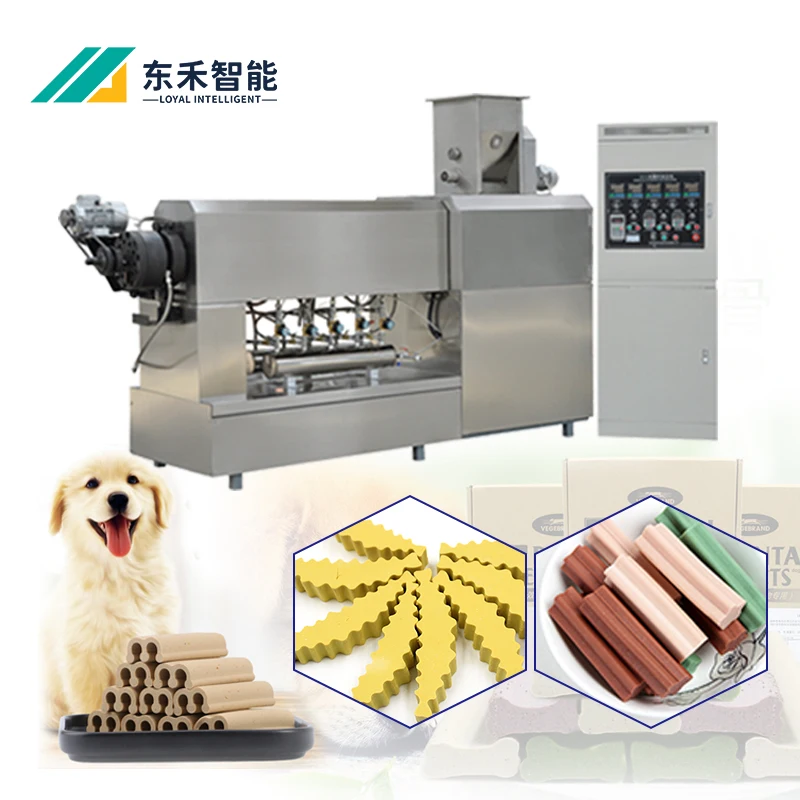

As the types of pets continue to increase, the market's requirements and demands for pet food have also continued to increase. Our company has researched and developed a variety of pet food production lines according to the needs of this market. Depending on the output, the production line also has a variety of configurations. The production line uses meat meal, fish meal, bone meal, corn meal, soybean meal, etc. as the main raw materials. The shape can be made into rods, bones, strips and other different shapes, and the color can also be optional. It can provide the dog with the necessary nutrients, such as protein, vitamins, fat, etc., and can also satisfy the dog's chewing preferences. This production line is widely used in the production of pet food such as dogs, cats, foxes, birds, etc. It is an ideal choice for large, medium and small manufacturers.

The soft chews dog treats making machine production line is specially used to produce dog chew products. It uses unique extrusion methods and molds to produce strips, rods, twists, two-color or multi-color foods with different shapes and sandwiches. During the soft chews dog treats making process, dog treat can moderately massage the dog's teeth, and at the same time promote the dog's salivation and help the dog to improve its digestive function. The products produced are made of natural food, wear-resistant, non-toxic and harmless. It has the function of grinding teeth and supplementing nutrition. By adjusting the formula, we can provide the dog with the necessary nutrients and satisfy the dog's preference for soft chews dog treats.

The soft chews dog treats making machine production line is specially used to produce dog chew products. It uses unique extrusion methods and molds to produce strips, rods, twists, two-color or multi-color foods with different shapes and sandwiches. During the soft chews dog treats making process, dog treat can moderately massage the dog's teeth, and at the same time promote the dog's salivation and help the dog to improve its digestive function. The products produced are made of natural food, wear-resistant, non-toxic and harmless. It has the function of grinding teeth and supplementing nutrition. By adjusting the formula, we can provide the dog with the necessary nutrients and satisfy the dog's preference for soft chews dog treats.

Production Process

Flour Mixer--Screw Conveyor--Single Screw Extruder--Cooling Conveyor--Cutting Machine--Oven--Packing Machine

Specification

1. Output | 2. 100kg/h, 200kg/h, 300kg/h, 500kg/h, 1000kg/h... |

2. Heating method | gas, electrical, diesel. |

3. Dog treat shape | bone shape, rod shape, twist shape, etc. can be customized |

4. Dog treat color | single color, double color, multi-color, etc., can be customized |

5. Equipment power | 46KW |

6. The size of the equipment | 15*2*2M |

Purpose and function of each soft chews dog treats making machine

Purpose and function of each soft chews dog treats making machine | ||

Equipment | Purpose and function | |

1. Mixing machine | Add a certain proportion of water to the raw materials and mix them evenly. | |

2. Screw conveyor | The motor is used for screw conveying, and the mixed raw materials are conveyed to the feeding hopper of the extruder to ensure convenient and fast feeding. | |

3. Single-screw extruder | Under the conditions of high temperature and high pressure environment and screw extrusion, different feeds can be produced by adjusting the process, and the specific particle size and shape can be changed. (If you want to do sandwich or two-color dog treat, you need two Extruder). | |

4. Cooling machine | Traction cooling and conveying. | |

5. Cutting machine | Cut the dog treat into different sizes according to requirements. | |

6. Packing machine | Pack the final product for easy storage and carrying, clean and hygienic | |

7. Oven | Dry the materials, reduce the moisture of the feed particles, promote the maturation rate, and increase the shelf life | |

Finished product display

Pet food production equipment can be applied to cats, dogs, foxes, monkeys, pigs, sheep, rabbits, fish, shrimps, poultry, birds, etc. The production equipment can adjust the process parameters of raw materials, temperature, moisture, etc. The size and shape of pet food can be adjusted by changing the mould and cutting speed. It can adjust the pet feed machine according to customers' requirement.

Machine details display

Packing & Delivery

Film&Wooden Box Packing

Company Profile

Shandong loyal intelligent machinery Co., Ltd. is a manufacturer of snacks extruder machine, hot air drying Machine, frying system, industrial microwave system, biscuit making machine, cereals bar making machine, fruit and nuts process making machine, instant noodle process machine and a standing director of China Food and Drying Equipment Industry Association.

The self-developed twin-screw extruder and single-screw equipment of shandong loyal intelligent machinery Machinery have been used in production: Puffed snack food, breakfast cereal corn flakes, fried pasta, bread crumbs, fruit chips, baby food, textured soy protein (TSP) food, fish feed and pet food. A variety of snack production line supporting products. At the same time, the batching, drying, flaking, baking, frying and spraying equipment matching the twin-screw extrusion system have all achieved independent design and production.

Our company can provide food production equipment, process, formula development and application for a wide range of users. We are able to provide customers with complete project solutions, advice, planning, project design and engineering for food plants according to their specific requirements. Complete turnkey systems, centralized control systems, complete plant automation projects. Provide the installation, commissioning of machines and training of workers for customers.

The self-developed twin-screw extruder and single-screw equipment of shandong loyal intelligent machinery Machinery have been used in production: Puffed snack food, breakfast cereal corn flakes, fried pasta, bread crumbs, fruit chips, baby food, textured soy protein (TSP) food, fish feed and pet food. A variety of snack production line supporting products. At the same time, the batching, drying, flaking, baking, frying and spraying equipment matching the twin-screw extrusion system have all achieved independent design and production.

Our company can provide food production equipment, process, formula development and application for a wide range of users. We are able to provide customers with complete project solutions, advice, planning, project design and engineering for food plants according to their specific requirements. Complete turnkey systems, centralized control systems, complete plant automation projects. Provide the installation, commissioning of machines and training of workers for customers.

FAQ

1. who are we?

We are based in Shandong, China, start from 2021,sell to South America(15.00%),South Asia(12.00%),Southeast Asia(11.00%),Africa(10.00%),North America(10.00%),Northern Europe(8.00%),Western Europe(7.00%),Eastern Europe(6.00%),Southern Europe(5.00%),Central America(5.00%),Mid East(4.00%),Oceania(3.00%),Eastern Asia(2.00%),Domestic Market(2.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Instant Noodles Production Line,Biscuit Production Line,Pet Food Production Line,Twin Screw Extruder,Puffing Snack Food Production Line

4. why should you buy from us not from other suppliers?

With 18 years of experience in the field of food machinery, we provide every customer with feasible solutions, from raw material processing to finished product packaging.

Quality control, new technology development and better customer service.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean

We are based in Shandong, China, start from 2021,sell to South America(15.00%),South Asia(12.00%),Southeast Asia(11.00%),Africa(10.00%),North America(10.00%),Northern Europe(8.00%),Western Europe(7.00%),Eastern Europe(6.00%),Southern Europe(5.00%),Central America(5.00%),Mid East(4.00%),Oceania(3.00%),Eastern Asia(2.00%),Domestic Market(2.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Instant Noodles Production Line,Biscuit Production Line,Pet Food Production Line,Twin Screw Extruder,Puffing Snack Food Production Line

4. why should you buy from us not from other suppliers?

With 18 years of experience in the field of food machinery, we provide every customer with feasible solutions, from raw material processing to finished product packaging.

Quality control, new technology development and better customer service.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.