Автоматическая машина для обработки миндаля автоматическая сбора

- Категория: Shellers >>>

- Поставщик: Zhengzhou,Youding,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 10115.17 $* | 10621.60 $* |

| Aug-19-2025 | 10030.33 $* | 10532.67 $* |

| Jul-19-2025 | 8415.75 $* | 8836.75 $* |

| Jun-19-2025 | 9860.33 $* | 10353.41 $* |

| May-19-2025 | 8585.10 $* | 9014.76 $* |

| Apr-19-2025 | 9690.2 $* | 10175.11 $* |

| Mar-19-2025 | 9605.6 $* | 10085.26 $* |

| Feb-19-2025 | 9520.75 $* | 9996.17 $* |

| Jan-19-2025 | 9435.69 $* | 9907.69 $* |

Характеристики

Product Application And Details

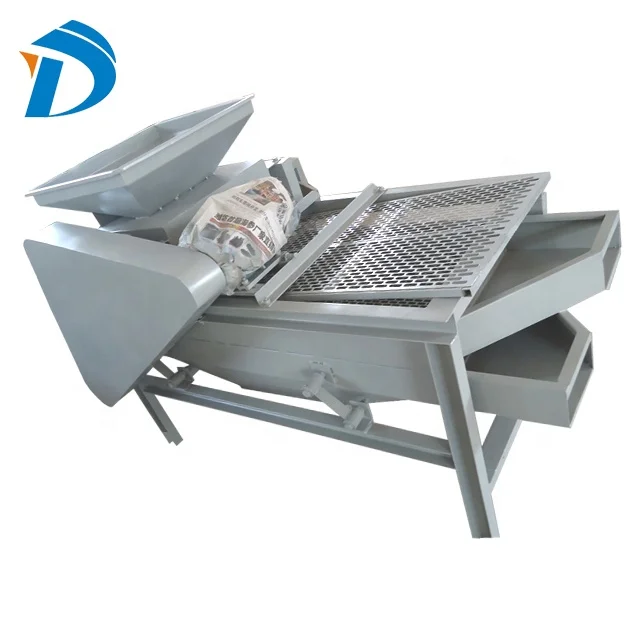

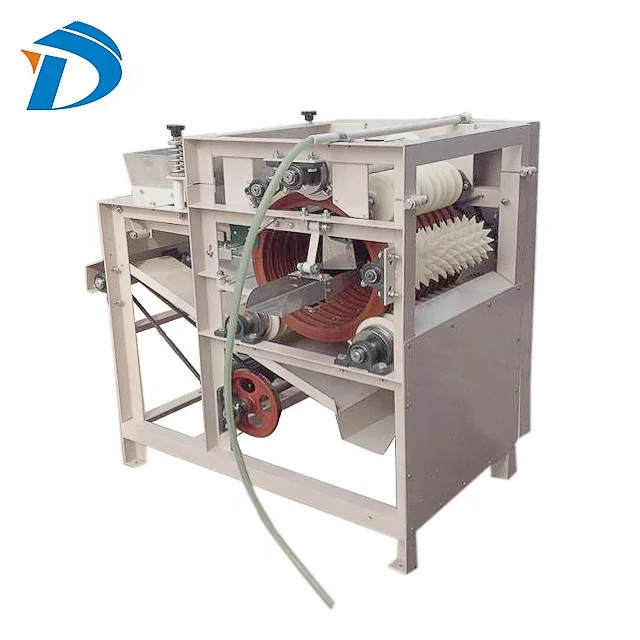

This machine professional use for broken the hard shell ,like the apricot and filbert to change the distance between

the rollers of this machine ,can broken the different size shell of the products .because the size of the shell is different, so it is better to broken the big size ,then broken the smaller size .

The almond seeds can not be injured after processing.

1.The almond sheller is suitable for cleaning, shelling, sorting almond,also can used for shelling walnut , high efficiency, large output, high degree of automation, production environment clean, is a professional device of choice of almond and walnut plants.

2.Through the hoister feeding,1,2,3 level grade broken,every grade is made up of discharging-sieve and vibrosieve,can strip 3 level grade different specifications of the apricot, walnut hard shell at the same time.

Model | YDS-40 | YDS-1000 |

Capacity | 400-500kg/h | 1000-1500kg/h |

Shelling rate | >95% | ﹥98% |

Broken rate | ﹤3% | ﹤3% |

Voltage | 220v/380v | 220v/380v |

Power | 2.2kw | 7.5kw |

Dimensions | 1900*900*1600mm | 3200*4500*2600mm |

Weight | 260kg | 2500kg |

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* Accurate quotation and technology analysis.

* Suggestions for related products and projects.

* View our Factory.

After-Sales Service

* Help installation and training.

* Technical support online all the time

* Repair or change new spare parts

* Employee working at factory long term

* Improve technology and equipment design for buyers

Packaging | ||

Size | loading containers | |

Weight | 2500kg | |

Packaging Details | The normal package is wooden box (Size: L*W*H). If export to european countries,the wooden box will be fumigated.If FCL shipment loading container directly at our factory ,we will use pe film and fixed by steel wire for packing or pack it according to customers special request. | |

Transportation way: By DHL.

We would have a supply for the parts of higher ware & tear with the initial shipment for free, the quantity as per corresponding sets of equipment.