Линия по производству искусственного песка

- Категория: Sand Making Machinery >>>

- Поставщик: Henan,Hongke,Heavy,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.80 $* | 0.57 $* |

| Aug-16-2025 | 0.57 $* | 0.90 $* |

| Jul-16-2025 | 0.16 $* | 0.52 $* |

| Jun-16-2025 | 0.70 $* | 0.80 $* |

| May-16-2025 | 0.16 $* | 0.36 $* |

| Apr-16-2025 | 0.30 $* | 0.97 $* |

| Mar-16-2025 | 0.97 $* | 0.22 $* |

| Feb-16-2025 | 0.43 $* | 0.6 $* |

| Jan-16-2025 | 0.87 $* | 0.34 $* |

Характеристики

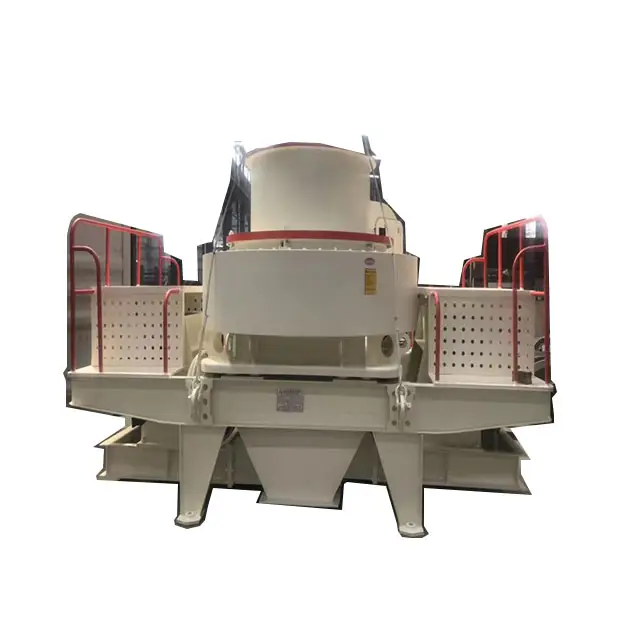

VSI Artificial Sand Making Line

Application Range of VSI sand making machine

1.VSI sand making machine can be used in Pebble,rock( the limestone, granite, basalt, aluminum, andesite, etc.), ore tailings, attle artificial sand production.

2.VSI sand making machine can be used in Building aggregate, highway, cushion, asphalt concrete and cement aggregate production.

3.VSI sand making machine and stone reshaping production in water conservancy and hydropower engineering field,highway,railway,bridge,passenger line,airport runway,municipal engineering and high-rise buildings.

4.VSI sand making machine with high abrasive materials resistance and secondary disassembly, desulphuration of thermal power and metallurgy, slag and construction waste.

5.VSI sand making machine can be used in the production of glass,quartz sand and other high purity material.

Features and Advantages of Small Sand Making Machine

1.VSI sand making machine with Large handling capacity and High output;50-500t/h, the output of VSI has been stably increased 30% comparing with the traditional equipment under the same motor power.

2.VSI sand making machine in Low wearing parts cost;Perfect impact angle design of the crushing cavity, less friction against the wearing parts. The operation cost reduces 40%.

3.VSI sand making machine with Perfect product shape. It fits especially man-made sand and stone reshaping.

4.VSI sand making machine Hydraulic devices are maintained easily;Hydraulic door-opened device make the repair in the crushing cavity easily .Shorten downtime and save effort.

5.The vertical shaft impact crusher Automatic test, safe and reliable;Vibration display and warning device are set. The machine will be warned to stop working when abnormal phenomenon appears.

6.VSI sand making machine Thinning oil lubricant and automatic maintenance;The original German thinning oil lubricant station, double-pump injection system guarantees the oil supply.

Working Principle of Small Sand Making Machine

1.VSI sand making machine materials fall into the crusher and are divided into two parts.

2.One part goes into the high-speed-running impeller of the machine, and the other part goes around the impeller.

3.The two parts materials bump and crush fast during the effect of centrifugal force.

4.Then the materials run like swirl, bump and rub to each other again and again.

5.The finished products go out from the bottom of the machine, and users can get the requested products size after screening by vibrating screen.

Main technical parameters of Small Sand Making Machine

| Model | Impeller speed (r/min) | Max feed size (mm) | Capacity(t/h) | Powder (kw) | Weight(kg) | Overall dimensions(mm) (L*W*H) |

| PCL-600 | 2000-3000 | 30 | 12-30 | 2*30 | 5.6 | 2800*1500*2030 |

| PCL-750 | 1500-2500 | 35 | 25-55 | 2*45 | 7.3 | 3300*1800*2440 |

| PCL-900A | 1200-2000 | 40 | 55-100 | 2*55 | 12.1 | 3750*2120*2660 |

| PCL-900B | 1000-1450 | 40 | 65-130 | 2*75 | 13.6 | 3750*2300*2090 |

| PCL-1050 | 1000-1700 | 45 | 100-160 | 2*(90-110) | 16.9 | 4480*2450*2906 |

| PCL-1250 | 850-1450 | 45 | 160-300 | 2*(132-180) | 22 | 4563*2650*3176 |

| PCL-1350 | 800-1200 | 50 | 200-360 | 2*(180-220) | 26 | 5340*2940*3650 |

About our factory

Kindly Note:

1. Please pay attention to the capacity. It's what you must take into consideration in choosing a suitable machine.

2. Please Inform us the follow figures:

1). feeding material

2). Feeding material MAX. Size (mm)

3). Final mesh size (mm)

4). Capacity (t/h)

Upon we got your message we shall give you our favorable offer in short time.