Трехслойная компрессионная машина для выдувания полиэтиленовой пленки модель

- Категория: Рукавных пленок производственная линия >>>

- Поставщик: Ruian,Huarui,Plastic,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 51170.24 $* | 53729.63 $* |

| Aug-20-2025 | 50740.39 $* | 53277.95 $* |

| Jul-20-2025 | 42570.10 $* | 44699.85 $* |

| Jun-20-2025 | 49880.8 $* | 52374.84 $* |

| May-20-2025 | 43430.3 $* | 45602.70 $* |

| Apr-20-2025 | 49020.66 $* | 51471.40 $* |

| Mar-20-2025 | 48590.38 $* | 51020.43 $* |

| Feb-20-2025 | 48160.11 $* | 50568.18 $* |

| Jan-20-2025 | 47730.56 $* | 50117.96 $* |

Характеристики

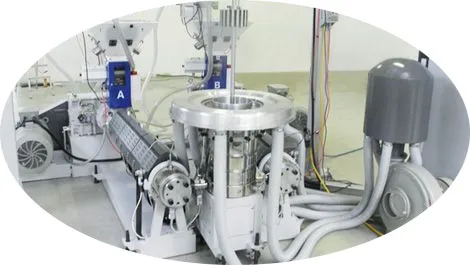

Three Layer Coextrude PE Film Blowing Machine Features

Model No. HR2SJSeries

1. Blown film extrusion spiral double layer high pressure type dies are accuracy made and also therefore are pricey however their life span is considerable. Each die head will have a working range of die inserts at different diameters to fit the needed application. Different die gaps can also be specified relying on the material being extruded.

2.The barrel and the screw of the extruder are made of high quality alloy steel with optimum hardness and durable service after precision finishing and nitrogen treatment. Main Motor direct connection with gear box, saving power energy consumption.

3.The auxiliary machine has a platform working table for making operation easy and is equipped with bubble stabilizing ring. The blown film procedure is a continual procedure, as such the machinery has to be designed to cope with both the high speeds involved and have the ability to operate on a 24 hour basis. As soon as the film has actually been blown, it is drawn off from the tower making use of secondary supplementary equipment. There are two types of take off winder, single station, or a tandem winder.

4.Double-winder and double-cutting unit adopts torque motor to keep proper tensions and make rolling even and easy to replace. Pneumatic surface friction winding unit, equipped AC motor with frequency conversion controller.

5. High efficiency dual lip air ring cooling system , SSR +PID temperature controller.

6.Optional electric spark coron treating device is available as required.

| Model | HR25J-55 | HR25J-60 | HR25J-65 |

| Screw diameter | 55*2 | 60*2 | 65*2 |

| Screw ratio L/D | 28: 1 | 28: 1 | 28: 1 |

| Screw speed | 15-65r/min | 15-65r/min | 15-65r/min |

| Main motor power | 15kw*2 | 18.5kw*2 | 22kw*2 |

| Extrusaion output(single) | 80kg/h | 100kg/h | 120kg/h |

| Range of die diameter | 220 | 350 | 420 |

| Max. folding width of film | 1000mm | 1500mm | 1800mm |

| single-side thickness of film | 0.02-0.12mm | 0.02-0.12mm | 0.02-0.12mm |

| Electric total capacity | 55 kw | 88 kw | 87 kw |

| Overall dimension | 6500*5500*5500 | 7500*5800*7500 | 7800*6400*8000 |

| Machine weight | 6.5T | 8.5T | 9.5T |

Three Layer Coextrude PE Film Blowing machine application

Blown co-extrusion film applications include:

1.Barrier film (e.g. film made of raw materials such as polyamides and EVOH acting as an aroma or oxygen barrier used for packaging food, e. g. cold meats and cheese), films for the packaging of medical products.

2.Agricultural film (e.g. greenhouse film, crop forcing film, silage film, silage stretch film).

Consumer packaging (e.g. packaging film for frozen products, shrink film for transport packaging, food wrap film, packaging bags, or form, fill and seal packaging film).

3.Industry packaging (e.g. shrink film, stretch film, bag film or container liners).

Laminating film (e.g. laminating of aluminum or paper used for packaging for example milk or coffee).

4.Blown film can be used either in tube form (e.g. for plastic bags and sacks) or the tube can be slit to form a sheet. Blown film extrusion can be used for the manufacture of co-extruded, double-layer or multi-layer films for high barrier applications such as food packaging.

Nowadays Huarui Machinery has been the symbol of high quality and excellent service in machinery industry, researched and developed our machines on basis of advanced technology following the highest level of the global. As a professional and experienced manufacturer in china, we're able to produce many kinds of machines like blown film machine, automatic polymer bag machine, gravure press and flexographic press, as well as blown film extruder inline with press etc. Through the collective assistance of our consumers around the globe, as well as the continual venture of the company staff have actually created an especial reputation for our enterprise worldwide.

Three Layer Coextrude PE Film Blowing machine advantages

2.Barrel and Screw have special nitrogen treatment.

3.Main Motor is driven by controller with frequency changer for stable running.

4.Double lip air ring cooling system to support the high speed capacity.

5.Take-up unit or tandem winder height can be adjusted freely.

6. All machines will be examined and tested before delivery by 5 professional engineers with more than 20 years manufacturing experience .Prompt Reply Within 12 Hours.

7.After-sale service, we had been continually dispatching own more than 10 experienced technicians abroad monthly, yearly production capacity over 200 units.

The method of higher efficiency of blown tubular film extrusion is to carry out co-extrusion that is the process of extruding two or more materials simultaneously through a single die unit. The orifices in the die unit are arranged such that the layers merge together before cooling. Co-extrusion is the economic means of producing layered films, and co-extrusion saves time because it extrudes two or more layers at the same time that provides a method with fewer steps to produce multiple layers film. Double layers co-extruder plasticizes two identical or different raw polymer by two extruders and extrude them into the complex die head, then produces the co-extruding molded complex film.

By this way, it make possible to enhance the film’s physical performance, hardness, homogeneous rigidity, good insulation-proof and impenetrability, meets the film’s quality requirement during the subsequent working procedure of the packing or printing machine, also is useable for manufacturing the complex packing film, insulation film, multi-functional farming film, etc. Blown film line is a co-extrusion machine to produce 2 layer AB or 3 layer ABA film, co-extrusion allows processors to combine different materials to meet a wide variety of demanding packaging applications. Raw material usually is LDPE, LLDPE, HDPE .

The double layer co-extrusion blown film extrusion line supports advanced consecutive rotation machine die head, to make film smooth, meets the film quality requirement.

Co-extrusion application allows unrelated materials with different characteristics to be combined in one tubular parison through special-designed die head. This combination binds different materials, such as combining high-gloss outside layer and inside barrier layer.

Three Layer Coextrude PE Film Blowing machine apllication

Three Layer Coextrude PE Film Blowing machine is applicable for the materials such as LDPE, LLDPE, HDPE, MLLDPE, EVA, EAA etc. It is widely used to manufacture composite film basic material, liquid film, contractive film, protective film, cable film, macromolecule adhesive film, multifunctional industrial film products.

Three Layer Coextrude PE Film Blowing machine characteristics

1.Die head is layer type spiral mandrel, continuous 3600 rotation.

2.Screen pack changer design is reliable, safe in operation and change the fitter screen easier.

3.Various functional parts may be installed to the lies. ,such as length counting device, vertical cutting device, cooling water row pipe, film spreading roller, scrap collecting device.

Three Layer Coextrude PE Film Blowing machine parameter

Model | SJ3-1000 | SJ3-1200 | SJ3-1500 |

Screw diameter(mm) | 55*2&60*1 | 60*2&65*1 | 65*2&70*1 |

Screw ratio(L/D) | 28:1 | 28:1 | 28:1 |

Screw speed | 15-150r/min | 15-150r/min | 15-150r/min |

Main motor power(kw) | 15*2&18.5*1 | 18.5*2&22*1 | 22*2&30*1 |

Output (single) | 150kg/h | 240kg/h | 300kg/h |

Die head diameter(mm) | 150&200 | 200&250 | 250&300 |

Thickness of film(mm) | 0.03-0.3 | 0.03-0.3 | 0.03-0.3 |

Max,folding width of film | 1000mm | 1200mm | 1500mm |

Total power | 76kw | 88kw | 102kw |

Weight | 4T | 5T | 6T |

Overall dimension(m) | 6.6*4.1*5 | 6.8*4.3*6 | 7*4.8*7.5 |

Product:

Characteristics :

This machine characters reasonable design, power consumptive and few, high output, suitable and in extensive range, reliable quality ,easy operation and maintain, profitable economy, is the ideal equipment which produces packing and agricultural plastic film canopy film of various kinds of packages printing.