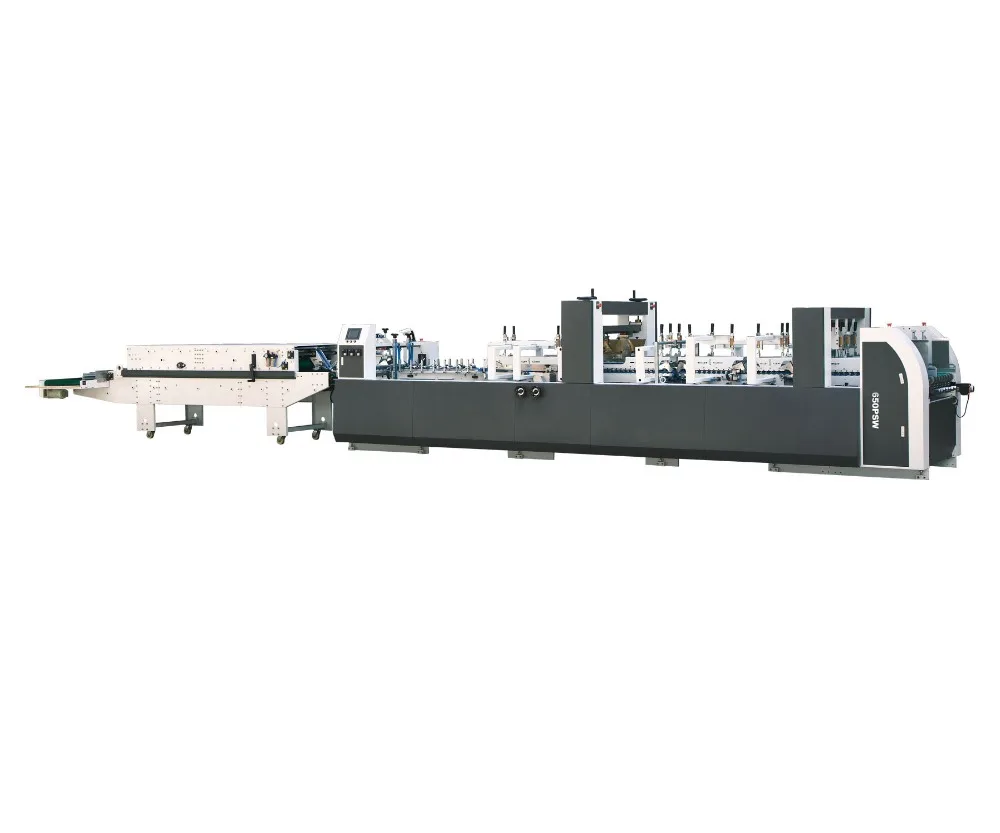

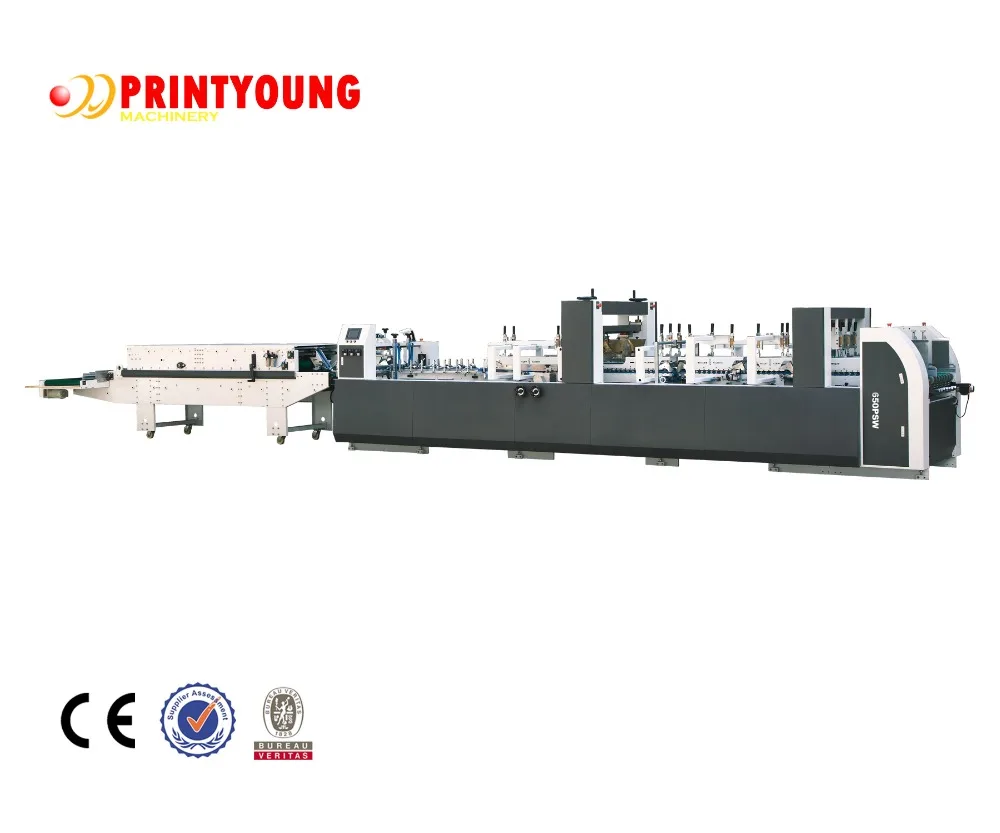

FH-650PS/PSW автоматическая машина для склеивания папок с дном

- Категория: Gluing Machines >>>

- Поставщик: Shanghai,Printyoung,International,Industry,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 35700.30 $* | 37485.42 $* |

| Aug-20-2025 | 35400.17 $* | 37170.4 $* |

| Jul-20-2025 | 29700.63 $* | 31185.36 $* |

| Jun-20-2025 | 34800.48 $* | 36540.81 $* |

| May-20-2025 | 30300.58 $* | 31815.3 $* |

| Apr-20-2025 | 34200.73 $* | 35910.24 $* |

| Mar-20-2025 | 33900.60 $* | 35595.89 $* |

| Feb-20-2025 | 33600.15 $* | 35280.15 $* |

| Jan-20-2025 | 33300.78 $* | 34965.57 $* |

Характеристики

FH-650PS/PSW AUTOMATIC FOLDER GLUER MACHINE WITH CRASH LOCK BOTTOM

Introduction:

FH-650PS/PSW AUTOMATIC FOLDER GLUER MACHINE WITH CRASH LOCK BOTTOM is the light molding machine, is mainly suitable in the carton packing and the card mounts the E wave the medium packing, like the cosmetics box, the kit and the liquor box, the small electrical appliances box and so on, The machine is two fold (four fold) with lock bottom, easy to adjust and operation.

Technical data:

Paper range: The cardboard, the laminate card and the E flute.

Feeding: Automatic continuous feeding

Max line speed: 250 meters/min

Max width of paper sheet : 80-650mm

Mechanical size: (L*W*H/M): 11×1.2×1.45m

Glue: Solvent-based

Weight: 6T

Power: 15KW

Type of the box | Side glue | Pre fold | Two side glue | Crash lock bottom | 4 corner |

| |||

Max size(mm) | 650*650 | 650*750 | 650*800 | 630*795 | 550*160 |

| |||

Min size(mm) | 70*70 | 70*70 | 100*65 | 140*60 | 300*130 |

| |||

| 4corner A mm B mm D mm |

A 550----160 B 300---130 D 70----20 | |||||||

Key components

Includes 6 sections: Feeder, Crash lock, Folder, Trombone, Conveyor and Transverse Conveyor.

Feeder section

Eight 25mm paper-feeding belts coordinate with vibration motor; 12mm medal plates horizontally adjust and set width, and embossing guide wheel guides paper-delivering belts; Guard plates are provided at right and left sides to move right and left in response to product patterns; Equipped with two delivery cutters to adjust asymmetric length depending on actual needs; The power of vibration motor can be adjusted depending on vibration rack; Achieves overall coordination to ensure easy, fast, automatic, continuous and accurate paper feeding; Equipped with stepless transmission to regulate paper-delivering distance.

Crash lock section

All gluing drums can be loaded and unloaded; Two upper gluing drums (right and left) and two lower gluing drums (right and left), to be selected depending on actual needs; Glue quantity in gluing drums is adjustable, thus ensuring stability and easy maintenance; Gluing roller is 5mm thick in standard version and can be customized according to customer requirements; Made with copper, gluing drum is firm and durable; Crash lock is completed by 4 groups of crash-locking mechanism.

Folder section

Composed of 30mm bottom belts and 30mm &50mm elbow belts; Right and lefts sides complete 180o second crease and 180ofourth crease; Right and left guide wheels allow flexible adjustment of different positions to facilitate folding; Lower bearings enable guide

Trombone section

Upper/lower drive mechanism to adjust length; Equipped with automatic belt tension-adjusting system; Adopts continuous and automatic box collecting mechanism to ensure boxes enter the Conveyor section neat and well aligned; Equipped with electronic counter, automatic mark spraying or kick plate can be chosen for counting purposes; Equipped with air compressor system and creasing channel system; Pressure rollers can be adjusted depending on box types and paper type to achieve flawless box creasing.

Conveyor section

Adopts 500mm-wide, 5mm-thick flexible belts imported from Italy, eliminating the risk of damage to products; Entire conveyor section can move forward and backward; Balanced pressure and neat convey to ensure flawless product quality; automatically regulates speed via host rotation speed in coordination with photoelectric device; also, speed can be manually regulated; Rubber rollers constitute a functional mechanism.

Transverse Conveyor section

Adjust belt speed depending on packing speed.