Индивидуальная энергосберегающая решетка высокой емкости/шаровая мельница для переливного и влажного

- Категория: Mine Mill >>>

- Поставщик: Shanghai,Yingyong,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.82 $* | 0.26 $* |

| Aug-16-2025 | 0.77 $* | 0.70 $* |

| Jul-16-2025 | 0.11 $* | 0.62 $* |

| Jun-16-2025 | 0.78 $* | 0.51 $* |

| May-16-2025 | 0.74 $* | 0.78 $* |

| Apr-16-2025 | 0.91 $* | 0.5 $* |

| Mar-16-2025 | 0.5 $* | 0.6 $* |

| Feb-16-2025 | 0.20 $* | 0.41 $* |

| Jan-16-2025 | 0.0 $* | 0.60 $* |

Характеристики

Product Description

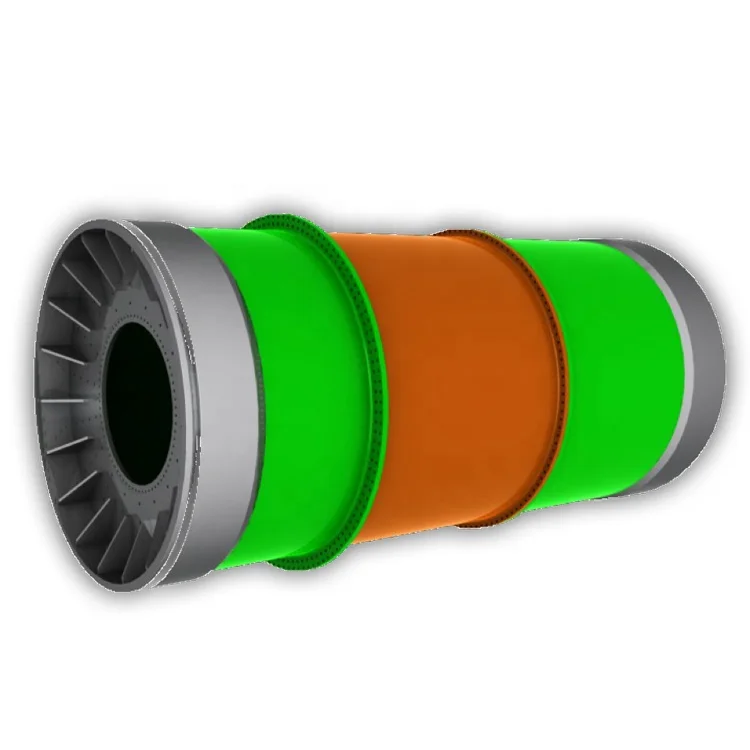

Wet Ball Mill

Ball mill can be used for many mineral grinding, such as gold ore, copper ore, iron ore and zinc ore and so on.

Type | Ball Mill |

Certification | ISO |

Power(kw) | 95-3300 |

Abrasive load | 4.8-280 |

Capacity(t/h) | Customized |

Weight | 30000 KG |

speed(r/min) | 16-29.2 |

Product Feature

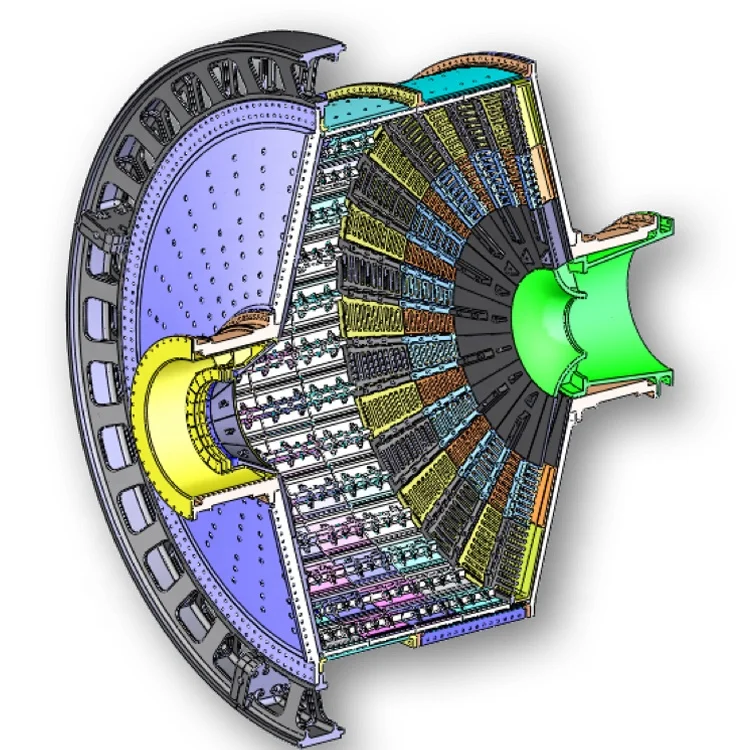

1. The transmission machinery of Energy-saving grate ball mill substitutes large-scale double row self-aligning roller bearing for sliding bearing. It is easy to start and saves energy up to 20-30%;

2. Energy-saving grate ball mill adopts groove-type circular lining plate that is instrumental in increasing contact areas of iron balls and ores, which enhances grinding action and ore lifting capacity and decreases energy consumption.

3. Energy-saving grate ball mill adopts whole milling house, which makes it easy for construction and installation.

4. Energy-saving grate ball mill has bigger discharge opening and huge processing capacity.

5. Energy-saving grate ball mill is equipped with oil-mist lubrication device which guarantees smooth operation of gears.

2. Energy-saving grate ball mill adopts groove-type circular lining plate that is instrumental in increasing contact areas of iron balls and ores, which enhances grinding action and ore lifting capacity and decreases energy consumption.

3. Energy-saving grate ball mill adopts whole milling house, which makes it easy for construction and installation.

4. Energy-saving grate ball mill has bigger discharge opening and huge processing capacity.

5. Energy-saving grate ball mill is equipped with oil-mist lubrication device which guarantees smooth operation of gears.

Working principle

Its main component is a cylinder with bigger diameter and smaller length which can revolve via the transmitting machinery. Materials are put in cylinder through the feed opening and then thoroughly grinded, because the falling course of iron balls and ores can produce huge falling impact and autogenous grinding. The continuous feeding of ores can create considerable pressure to make ores move from feed opening toward discharge opening. Finally, acceptable particles are discharged from the discharge opening. Acceptable ore particles are carried away by water by wet mill, or by air by dry mill. The discharge opening is equipped with a discharge grate, and the ore pulp horizon of discharge opening is low. These two factors prevent ores from being overly grinded, and iron balls from being dismissed. Under same circumstance, the processing capacity of energy-saving grate ball mill is bigger. Rolling bearings contribute enormous energy saving.

Product Advantages

1. Energy-saving grate ball mill is easy to start and save energy up to 20-30%

2. Energy-saving grate ball mill adopts groove-type circular lining plate that is instrumental in increasing contact areas of iron balls and ores

2. Energy-saving grate ball mill adopts groove-type circular lining plate that is instrumental in increasing contact areas of iron balls and ores

Application

Mill is essential and widely used equipment for raw material crushing. Its main component is a cylinder with bigger diameter and smaller length which is revolved by transmitting machinery. Materials are put in cylinder through the feed opening and then thoroughly grinded. The falling course of iron balls and ores can produce huge falling impact and autogenous grinding. The continuous feeding of ores can create considerable pressure to make ores move from feed opening toward discharge opening. Finally, acceptable particles are discharged from the discharge opening. Acceptable ore particles are carried away by water in wet mill, or by air in dry mill.

Technical parameters

Production Capacity

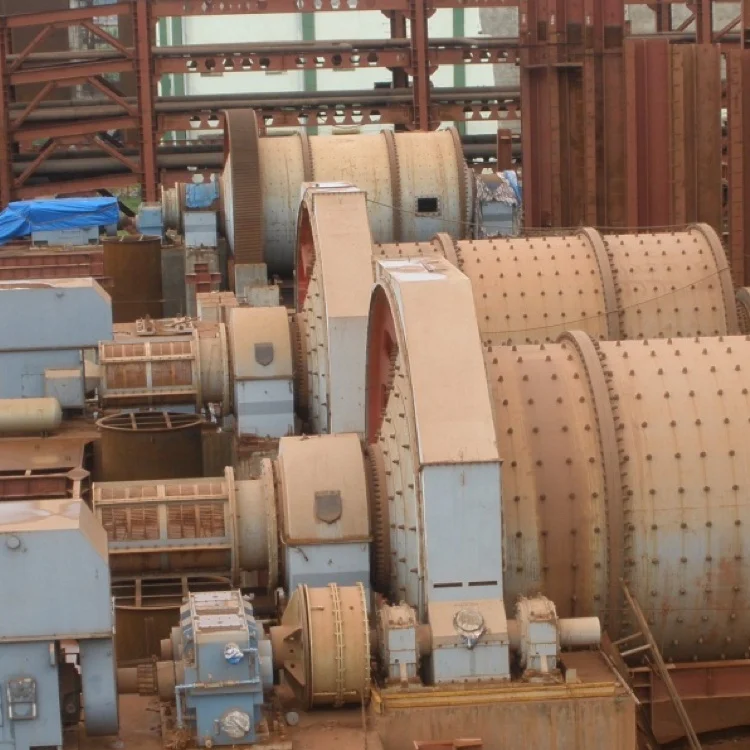

Quality Control

Company Profie

Our Business

Custom Visiting

FAQ

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.