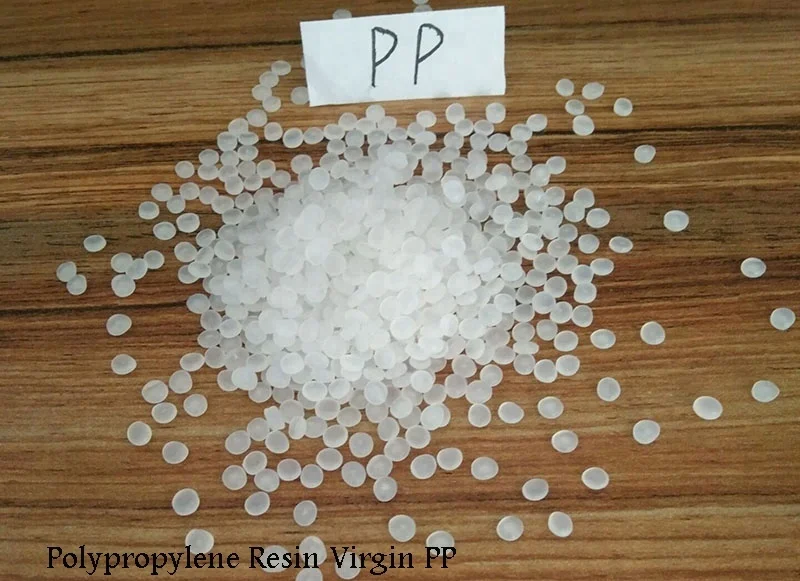

Переработанные полипропиленовые гранулы по заводской цене первичные 25 кг или 50 кг/пакет из

- Категория: ПП >>>

- Поставщик: ALEX,2020,LIMITED

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 476.76 $* | 500.44 $* |

| Aug-18-2025 | 472.37 $* | 496.70 $* |

| Jul-18-2025 | 396.39 $* | 416.48 $* |

| Jun-18-2025 | 464.42 $* | 487.76 $* |

| May-18-2025 | 404.33 $* | 424.8 $* |

| Apr-18-2025 | 456.61 $* | 479.74 $* |

| Mar-18-2025 | 452.12 $* | 475.1 $* |

| Feb-18-2025 | 448.68 $* | 470.73 $* |

| Jan-18-2025 | 444.11 $* | 466.23 $* |

Характеристики

PP PP is a nontoxic, odorless, odorless, tasteless, creamy, high crystalline polymer with a density of only 0.90 --" 0.91g /cm3, "one of the lightest plastics available. It is particularly stable for water, with a water absorption rate of 0.01% and a molecular weight of about 81,150,000. Good molding performance, but due to large shrinkage rate (1%~2.5%), thick wall products are easy to sag, it is difficult to meet the requirements for some parts with high dimensional precision, and the surface of products is glossy.

I. PRODUCT INTRODUCTION:White MasterBatch 2~3mm PE-carrier TiO2 content 30~70% Dosage 1~8%

Vical PP is a filler masterbatch, based on Calcium Carbonate (CaCO3). This product is manufactured in Vietnam by We widely used to reduce the production cost and improve the plastic product’s characters: improve the surface antifriction, heat stability, toughness, hardness, rigidity and increase specific gravity of products.

Vical PP contains CaCO3, resin, dispersion agent, processing aid. It’s compatible with PP, ABS, PS… and suitable for PP threading yarn, injection, blow molding, extrusion, etc.

Vical PP content No-Heavy metal and Nonyphenol, this product is completely suitable for food contact.

II. PRODUCT APPLICATION:

1. PP Woven sack % FIBC;

2. Non – Woven;

3. Injection Molding.

4. Extrusion

5

III. MAIN GRADES: 78% – 88% CaCO3

| Items | Method of experiment | Value |

| Calcium Carbonate (CaCO3) content | ASTM D 5630 | 78% – 88% ± 0.5 |

| Particle size of CaCO3 Powder | Malvern | 2 – 3.5 µm |

| Melt Mass-Flow Rate (230°C/2.16kgs) | ASTM D 1238 | 13 g/10 mins ± 2 |

| Melt Temperature | DSC | 150°C |

| Bulk density | ASTM D 1895 | 1.2 g/cm3 |

| Moisture | ASTM D 644 | < 0.15% |

Properties:

Additives: Dispersion agent, Processing aid Processing temperature: 180°C – 280°C

Carrier resin: PP Polypropylene Appearance: White

Compatibility: PP, PS, ABS… Pellet Size: 3×3 (±0.3) mm

Usage rate: 5% – 40 % Packing: 25 kgs per PE/PP bag

WHITE MASTERBATCH

These masterbatches are produced using micronized grades of Titanium dioxide

- Organic pigmet : Safe for your all applications

- High durability

- High load-ability, no effect to the strength and quality of your output with our suggested mix rate

- Heat stability up to 270-300c, will not be faded under hot weather

- Improve whiteness with high quality of Ti02 and flow properties

- Well dissovle in your plastics compound

Application : Packaging application , Yarn and Injection moulding , Multi -layer and blow moulding.

If you have requirement, don’t hesitate contact with us. We are willing to suppporting you with competitive - price and best- way.

To support better, pls feel free contact us :