Лабораторный эмульсионный миксер гомогенизатор реактора из нержавеющей стали небольшого объема 1 л 2 5

- Категория: Mixing Equipment >>>

- Поставщик: Guangzhou,Yuhua,Instrument,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.64 $* | 0.65 $* |

| Aug-19-2025 | 0.60 $* | 0.76 $* |

| Jul-19-2025 | 0.83 $* | 0.39 $* |

| Jun-19-2025 | 0.80 $* | 0.24 $* |

| May-19-2025 | 0.1 $* | 0.92 $* |

| Apr-19-2025 | 0.48 $* | 0.70 $* |

| Mar-19-2025 | 0.28 $* | 0.52 $* |

| Feb-19-2025 | 0.88 $* | 0.11 $* |

| Jan-19-2025 | 0.15 $* | 0.15 $* |

Характеристики

1L 2L 5L 10L Lab Emulsifying Mixer Small Volume Stainless Steel Reactor Homogenizer

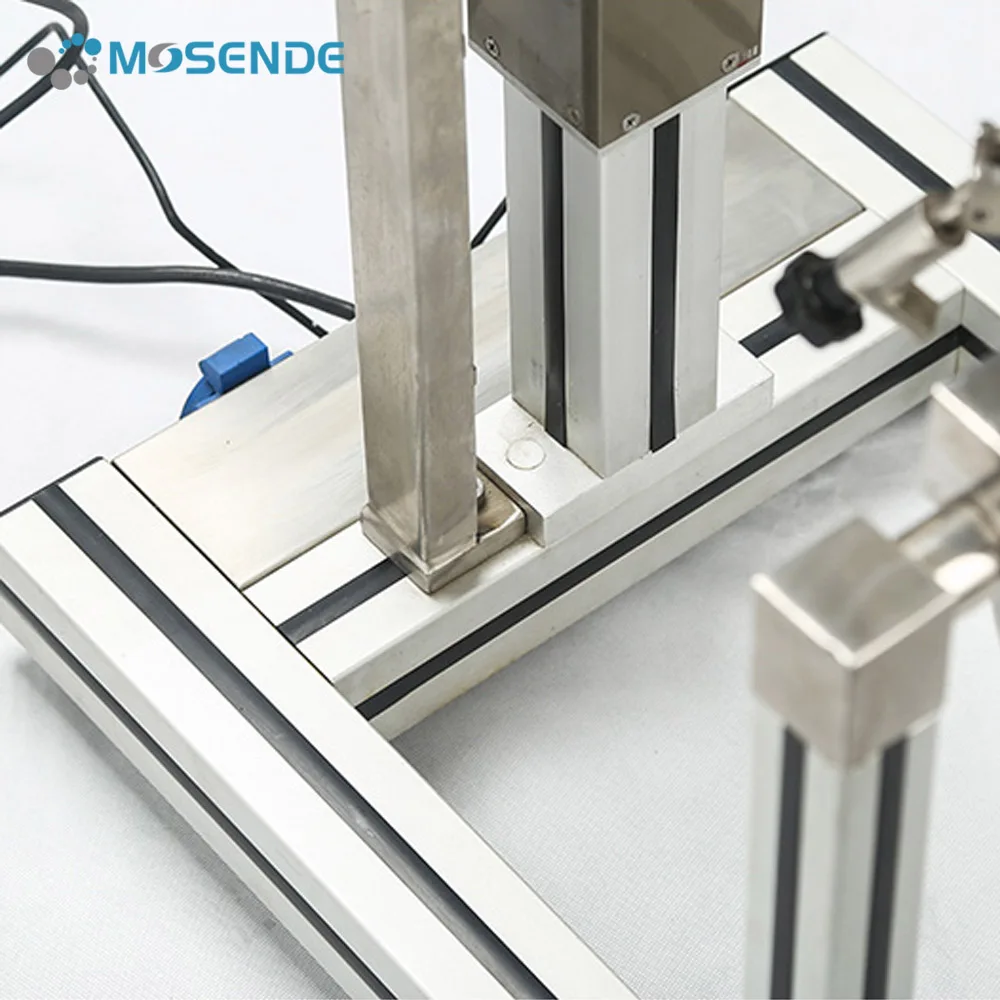

XHCR series emulsification kettle, the processing capacity of the standard system has 1-5l experimental / 10l-50l pilot type and 100-500l production type different series, which can realize material dispersion, emulsification, homogenization, mixing and other technological processes under vacuum or pressure environment. It can be equipped with a variety of high-efficiency macro agitators, high shear homogenizer, reliable vacuum sealing system and temperature control system, and a variety of sensor detection systems can simulate industrial production in the laboratory environment.

Device configuration:

Model | XHCR-1 | XHCR-2 | XHCR-5 | XHCR-10 |

Power Supply | 220V,50/60Hz | 220V,50/60Hz | 220V,50/60Hz | 220V,50/60Hz |

Allowed mixing volume (ML) | 300 | 500 | 1000 | 2500 |

Allowable emulsification amount (ML) | 500-1000 | 1000-2000 | 3000-5000 | 5000-10000 |

Working temperature (℃) | 170 | 170 | 290 | 290 |

Vacuum attainable (MPA) | -0.097---0.02 | -0.097---0.02 | -0.097---0.02 | -0.097---0.02 |

Treatment viscosity (MPAs) | 100,000 | 100,000 | 200,000 | 300,000 |

Mixing motor power (W) | 90 | 90 | 120 | 180 |

Mixing speed range (RPM) | 100,000 | 100,000 | 100,000 | 100,000 |

Agitator configuration | Anchor type screw blade | |||

Scraper material | PTFE | |||

Homogeneous motor power (W) | 500 | 500 | 500 | 1050 |

Homogeneous speed range (RPM) | 10000-28000 | 10000-30000 | 10000-30000 | 10000-30000 |

Homogeneous working head configuration | 20DG | 25DG | 25DG | 30DG |

Reactor cover opening | Homogenizer port + hopper port + temperature measuring port + vacuum port + 3 spare ports | |||

Travel of lifting bracket (mm) | 210 (Electric lifting options) | 210 (Electric lifting options) | 300 (Electric lifting options) | 270 (Electric lifting options) |

Main contact materials with materials | SS316L,Borosilicate glass,FKM10 | |||

Outer diameter of vacuum port (mm) | 8 | 8 | 8 | 8 |

Allowable ambient temperature (℃) | 12 | 12 | 16 | 16 |

Allowable ambient temperature (℃) | 5-40 | 5-40 | 5-40 | 5-40 |

Reactor can be customized according to customer requirements

Optional laboratory reactor, laboratory homogeneous reactor, laboratory vacuum reactor

1) Reactor system (stainless steel and glass optional)

2) Emulsification system (emulsification homogenization head optional)

3) Mixing system (digital timing mixer optional)

4) Temperature control system (temperature probe optional)

5) Lifting system (pneumatic auxiliary and electric lifting optional)

6) Vacuum system (vacuum pump)

7) Heating system (water bath or oil bath)

8) On line monitoring systemOperation steps of the whole machine:

1. Before starting the machine, the water medium without impurities shall be used as the test machine, and the kettle with water without impurities shall be fixed on the support arm of the kettle.

2. Adjust the rotation speed of the mixing motor from slow to fast, start the randomly configured emulsifier to work at the same time, and observe the mixing of materials in the kettle.

3. In the process of operation, if there is serious swing around the mixing paddle, abnormal operation sound of the equipment, or serious vibration of the whole machine, it is necessary to stop the machine for inspection, and continue the operation after troubleshooting. (if the fault cannot be eliminated, please contact the after-sales service department of the company in time)

4. In the process of trial operation, if the equipment operates normally, it can be formally put into use in later experiments.

5. When conducting the experiment, please follow the operation instructions of the relevant safety regulations of the laboratory, and do not operate in violation of the regulations.

6. Do not hit or pull the mixing paddle, which will easily cause the unbalanced operation of the mixing paddle or the unstable operation of the shaft. The equipment must be handled carefully to ensure the safe operation and service life of the equipment.

7. It is strictly prohibited to carry out the experiment when the glass kettle is not concentric with the stirring paddle or the stirring paddle is in unbalanced operation in the glass kettle, which is very likely to cause equipment damage or accident.

8. Clean the equipment in time after each experiment.

9. After the completion of the experiment, the materials or stains stained on the equipment body must be wiped with a soft cloth. If it is difficult to wipe the stains, the soft cloth can be dipped with a little organic solvent for wiping. However, it should be noted that the solvent that may corrode the equipment body cannot be used for wiping.Cleaning, sterilization:

After each experiment, it should be cleaned in time. Generally, it is only necessary to clean the parts with material contact such as reaction kettle, agitator and working head. In general, only clean with water. For materials that are difficult to clean, appropriate organic solvent can be selected for cleaning, then clean with water, and finally clean with a clean soft cloth.

Autoclave cover, dispersion head and contact material can be disassembled for high temperature sterilization.

Where's your company? How do I get to your company?

Our company is located in Building A3, Dongtai Founder Industrial Park, No. 78 Luntou Road, Haizhu District, Guangzhou City, Guangdong Province, China. You can fly to Guangzhou Baiyun International Airport, and then we will arrange a special person to pick you up.

Are you a what type company?

We are an innovative enterprise integrating processing, manufacturing and trade.

What kind of service does it offer?

We can provide customers with common laboratory equipment and equipment and pharmaceutical, chemical industry applications of reactor tanks and supporting temperature control equipment.

How strong is your company?

Our company was founded in 2006, has its own leading brand in the country, our products sell well in China, covering most of the laboratories, deeply loved and praised by users. We have many cooperative production bases in different cities in China, concentrating the best production resources and providing the best quality products. We design a wide range of products, we have professional technical engineers, can provide customers with solution design, product customization services.

How about the quality of your products?

Product quality is not only a customer concern, but also our most important issue! We even the importance of product quality, the company has set up a strict testing system, only after strict performance testing of products, issued testing certificates can be allowed to leave the factory, you can rest assured to buy.