Роликовая мельница тальк серия Clirik YGM

- Категория: Горнообогатительная установка >>>

- Поставщик: Shanghai,Clirik,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 21420.3 $* | 22491.30 $* |

| Aug-17-2025 | 21240.38 $* | 22302.89 $* |

| Jul-17-2025 | 17820.42 $* | 18711.45 $* |

| Jun-17-2025 | 20880.3 $* | 21924.65 $* |

| May-17-2025 | 18180.75 $* | 19089.86 $* |

| Apr-17-2025 | 20520.96 $* | 21546.71 $* |

| Mar-17-2025 | 20340.54 $* | 21357.53 $* |

| Feb-17-2025 | 20160.22 $* | 21168.91 $* |

| Jan-17-2025 | 19980.96 $* | 20979.48 $* |

Характеристики

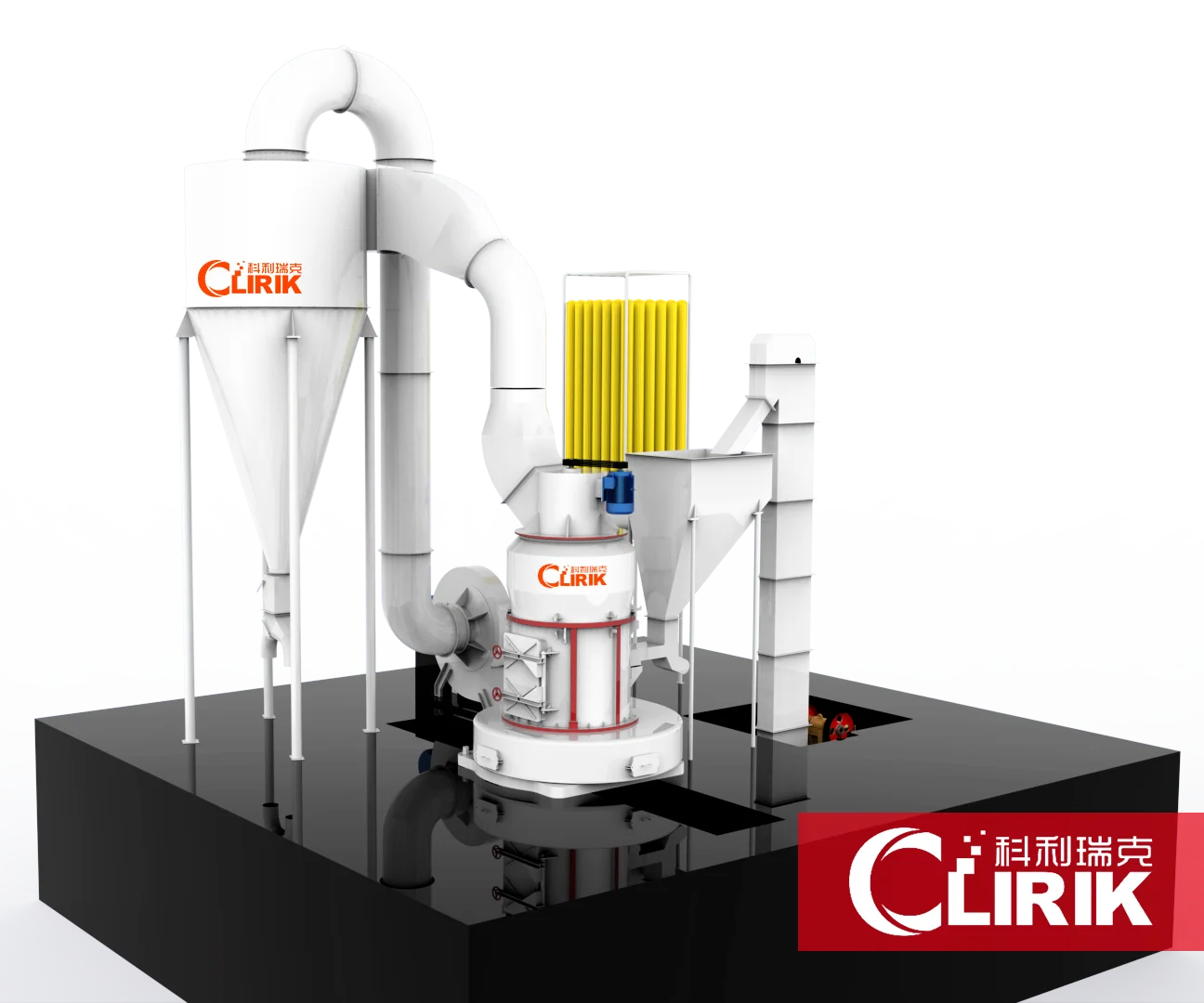

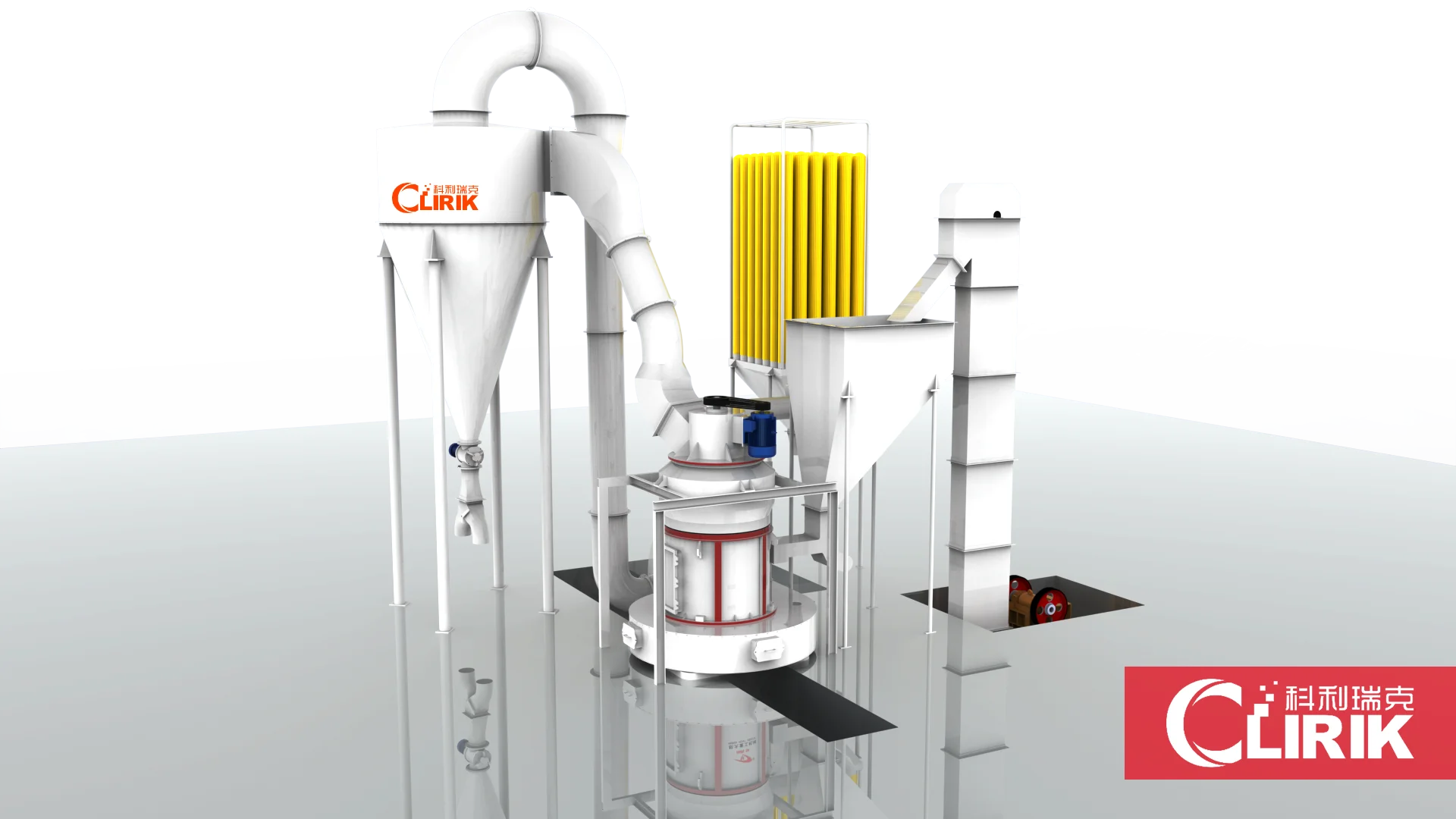

Clirik YGM Series Talc Powder Raymond Roller Mill Introduction

Name: Clirik YGM Series Talc Powder Raymond Roller Mill

Model: YGM series

Brand: Clirik

Powder Fineness Process Ability: 50-450 mesh

Capacity: according to your demand about powder fineness, the finial capacity can be adjusted between 0.5-28 t/h

Use Range: can be used in more than 300 kinds of stone materials powder grinding, such as: calcite, calcium carbonate, dolomite, gypsum, carbon black, gypsum, kaolin, marble and so on

Application: mining, chemiscal, transport and many other different areas

Clirik YGM Series Talc Powder Raymond Roller Mill Application

YGM Raymond roller mill is mainly used for grinding the material with middle and low hardness, below 6% moisture, and the material should be non-explosion and non-flammability, such as: calcite, chalk,limestone, dolomite, kaolin, bentonite, steatite, mica, magnetite,iolite, pyrophillite, vermiculite, meerschaum, attapulgite, diatomite, barite, gypsum, alunite, graphite, fluorite, phosphate ore, potassium ore pumice, etc

Clirik YGM Series Talc Powder Raymond Roller Mill Advantages

1. Energy Saving: compare with the comon stone powder grinding machine, the YGM Raymond Roller Mill can decrease about 20%~30% electrinic consums

2. Long Service Life: because the grinding ring and roller are forged by special material with high utilization. Under the same grinding material and finish special size, the lifecycle of spare parts is about one year, which is 2-3 times longer than impact mill or turbo mill

3. Environment Friendly: the application of pulse bag filter and muffler greatly alleviates dust pollution and noise

4. Cheaper Price& High Quality: because our Shanghai Clirik is the YGM Raymond roller mill, so you can get machine from us in the cheapest price, and at the same time we also can supply the warmly after sale service

Clirik YGM Series Talc Powder Raymond Roller Mill Working Principle

When the grinding mill is at work, the main bearing and each dial are driven by electromotor through reducer, and all the grinding rollers are rolling in the ring channels driving by dial through plunger. The materials are driven to the edge of the turn plate by the centrifugal force and fall down into the grinding chambers. The high-pressure air blower constantly inhales air, airflow with crushed materials are brought to classifier whose high-speed impeller will screen the airflow: The unqualified particle size will fall and return to the mill for being reground while the qualified particle size mixed with air will go into the cyclone powder collector. Most of the qualified powders will fall and exit from the discharging valve at the bottom; A small proportion of the fine powders, with airflow, moves to the dust cleaner. The materials from the above two lots are sent by the conveyor to get finished powders packed. In addition, filtered clean air will be emitted from muffler in the end.

Clirik YGM Series Talc Powder Raymond Roller Mill Technology Data

| Model | Roller | Ring | Feeding Size(mm) | Finished Size(mm) | Mill System Power(KW) | Capacity (t/h) | Overall Dimension (mm) | |||

| Quantity (piece) | Diameter (mm) | Height (mm) | Inner Diameter (mm) | Height (mm) | ||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1.0-3.0 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12.0 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16.0 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8.0-20.0 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28.0 | 11550*9500*10500 |

1.Seaworthy packing with sheet, fixed box, etc.

2. Container Loading

3. Delivery time: 15 days after receiving deposit.

4. All payment terms are available.

Shanghai Clirik Machinery Co., Ltd located in Pudong New district of Shanghai china, as a pioneer enterprise, which is specializing in research, manufacture and sales of all kinds of grinding mill, from coarse grinding mill, fine grinding mill and ultra fine grinding mill, grinding mill related equipment, such as powder modifying machine, powder packing machine.powder conveying system, etc. We have devoted into grinding field for more than 30 years, we beliveonly focus can be professional.

Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

Our Company

Our Certification

Our Working Site

Our Customers Visiting

Our Exhibition

Pre-Sales Service

♥Online interactive service

♥Offline interactive service

♥Solution design service

♥Visit reception service

After-Sales Service

♥Installation and debugging service

♥Training service

♥Other more service(Clients have any needs or problems; our engineer can take plane and get the worksite to provide service in 48 hours.)

Because there 5 different kinds of ultrafine grinding mills, so our HGM series grinding mill unit has different prices, I need to ask you some details for sending you the more suitable quotation:

1.Which kind of material you are going to grinding?

(Dolomite; Calcite; Quartz; Basalt; Barite; Feldspar ; Gravel; Bentonite; Gypsum; Granite; Coal; Slag; Pebble; Others )

2. What's the production capacity you want? How many tons or cubic meters per hour?

( > 100 TPH > 50 TPH > 30 TPH > 10 TPH > 1 TPH < 1 TPH)

3.What's the granularity of the final products you need?

(in milimeter, micron or mesh)

4. What's the max input size of the material?

(In inch,centimeter or milimeter)

We will give you factory price with full specification,so pls leave us an inquiry to know more details about price, packaging shipping and discount.

Shanghai Clirik Machinery