Источник производители поставляют цилиндр палец металлическая фурнитура достаточно доступной

- Категория: Metal & Metallurgy Machinery Parts >>>

- Поставщик: Zhejiang,Weidao,Metal,Products,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 5.89 $* | 5.77 $* |

| Aug-17-2025 | 5.52 $* | 5.25 $* |

| Jul-17-2025 | 4.97 $* | 4.88 $* |

| Jun-17-2025 | 5.10 $* | 5.52 $* |

| May-17-2025 | 4.76 $* | 4.49 $* |

| Apr-17-2025 | 5.31 $* | 5.64 $* |

| Mar-17-2025 | 5.28 $* | 5.99 $* |

| Feb-17-2025 | 4.59 $* | 4.4 $* |

| Jan-17-2025 | 4.41 $* | 4.80 $* |

Характеристики

Product Description

Specification

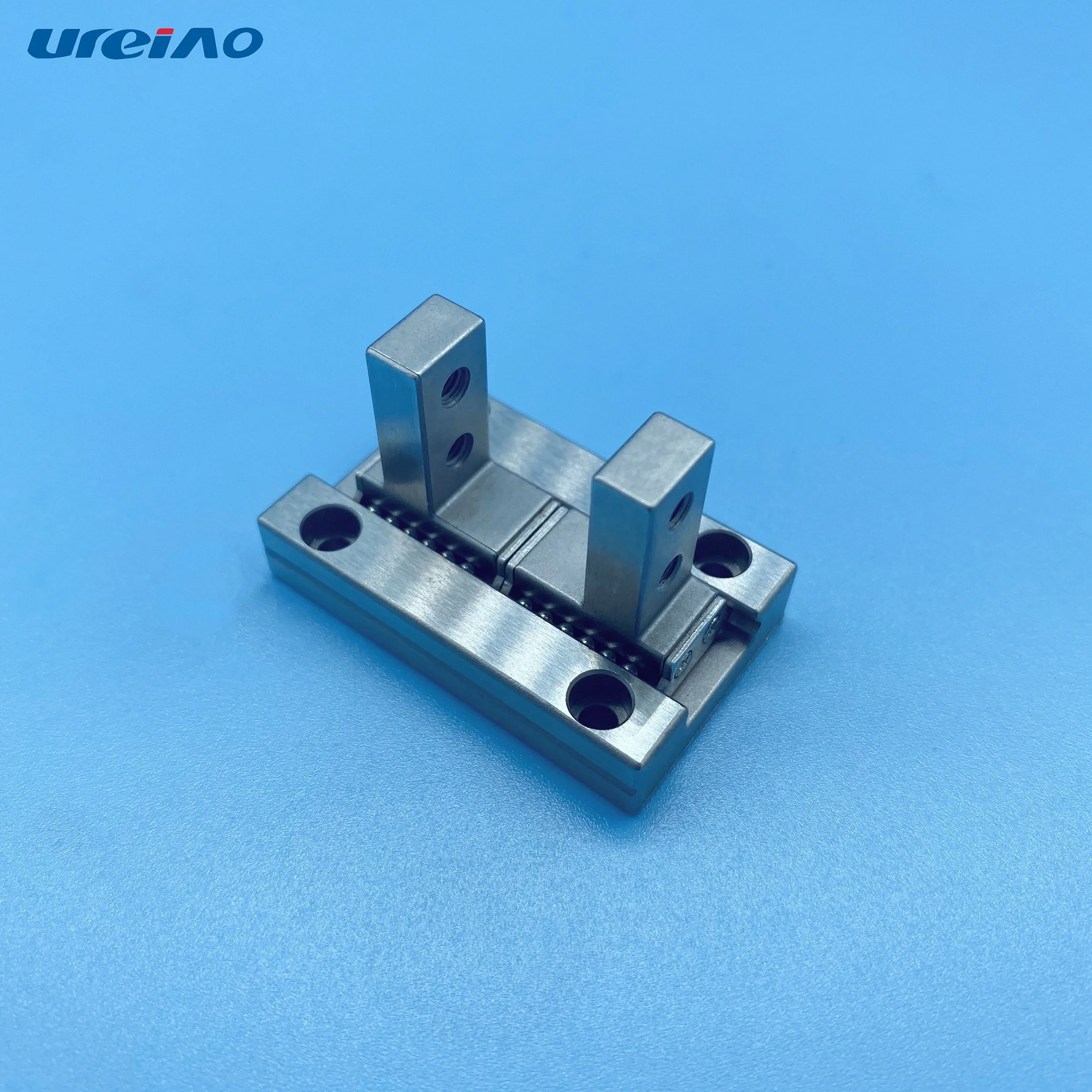

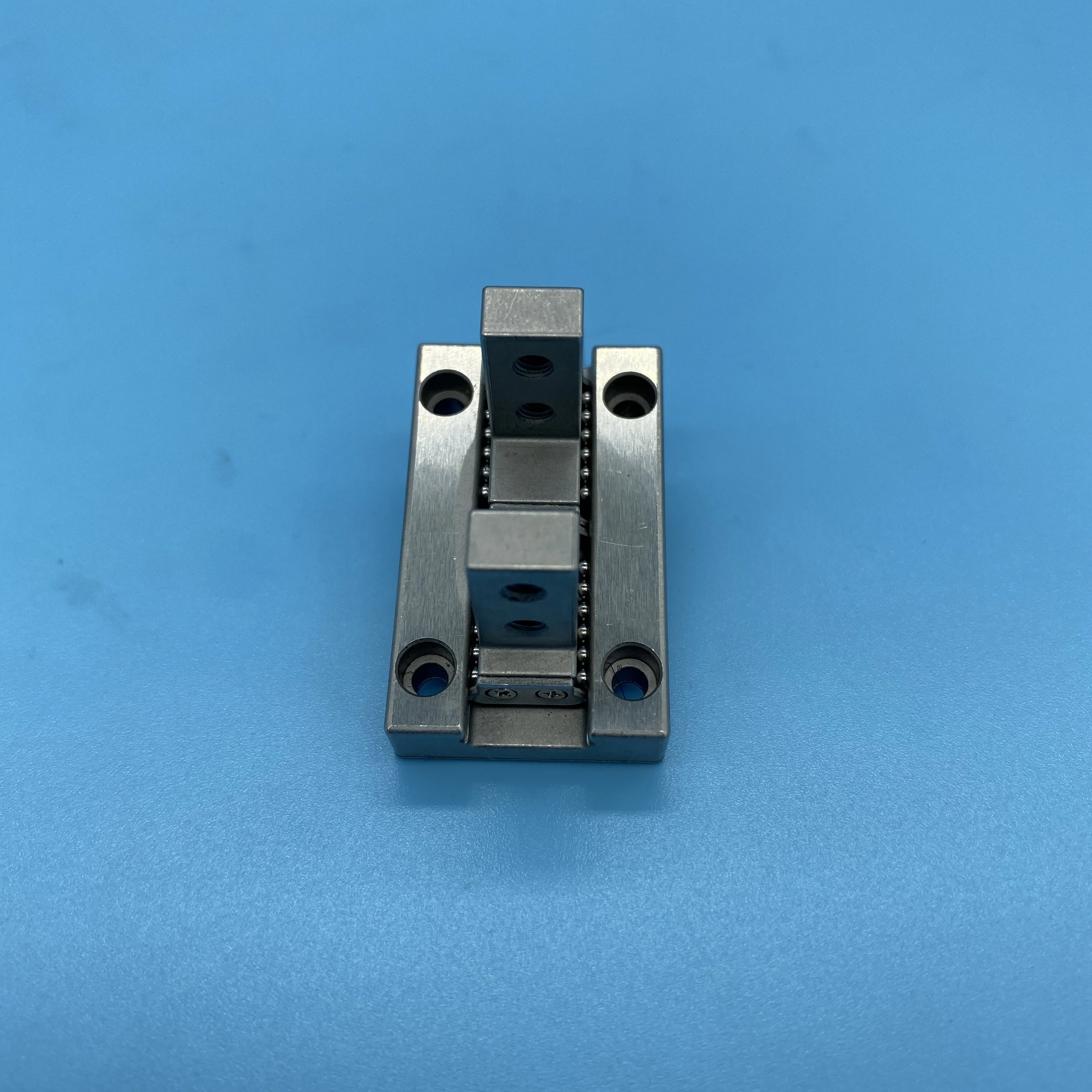

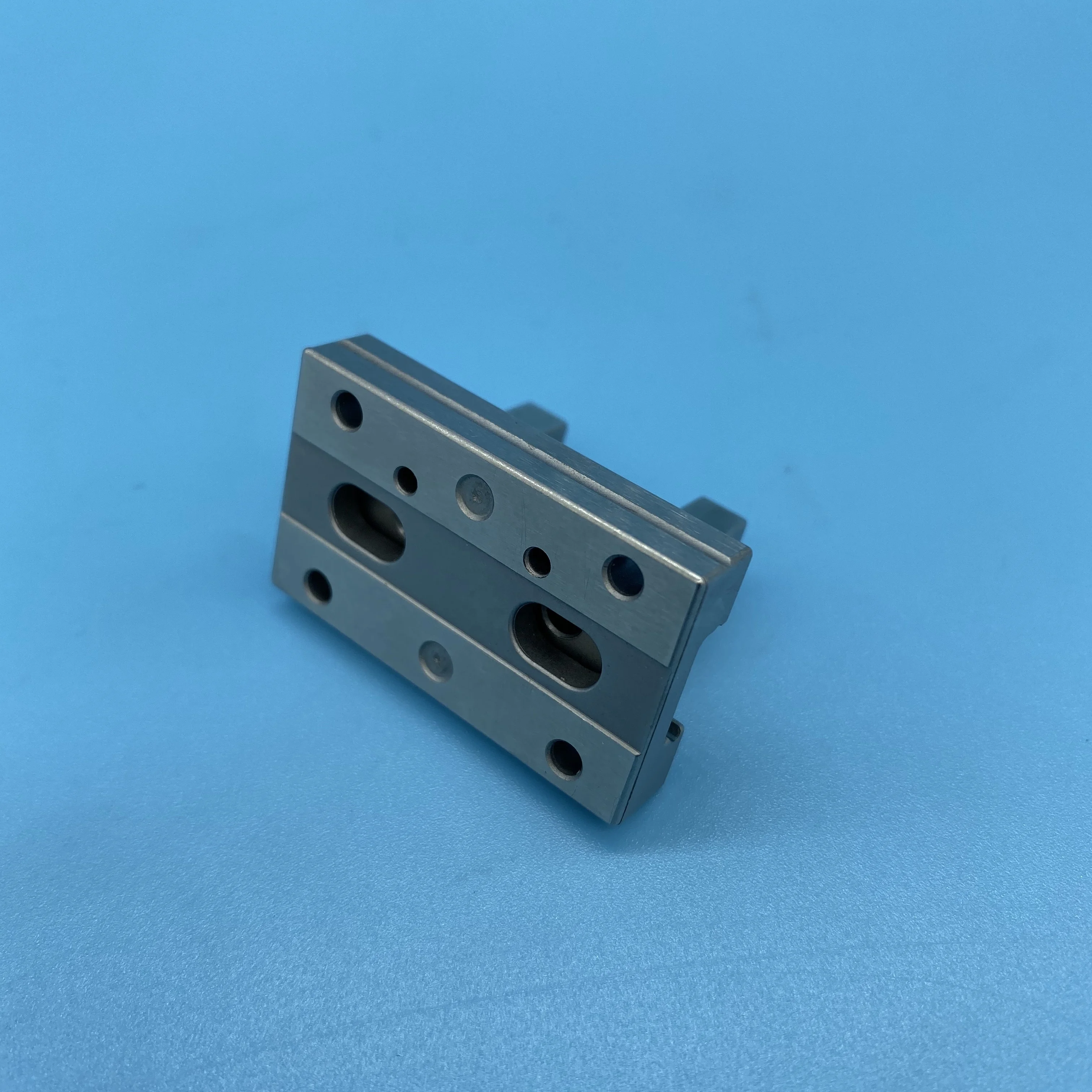

Place of Origin | China | Brand Name | urao | |

Type | MHZ2-16D | Material | Stainless steel | |

Plating | Certification | ISO:9001 | ||

Surface Finish | Polish | Customized | Yes | |

Quoted Condition | 2D/3D Drawing/Sample | Package | Standard Industrial Packing |

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profie

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for

producing PET plastic containers and bottles in all shapes.

producing PET plastic containers and bottles in all shapes.

FAQ

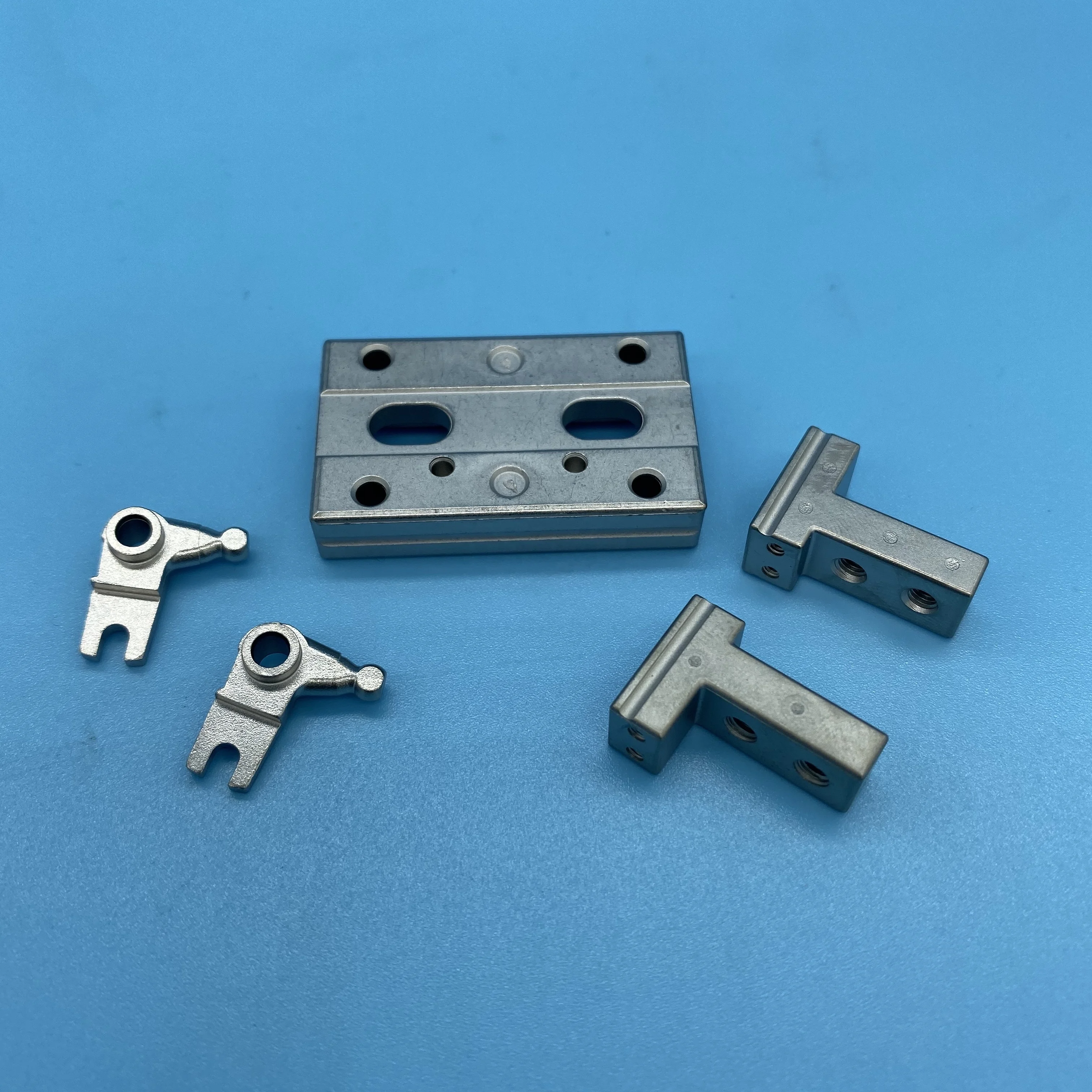

Q: What is MIM technology?

A: MIM(Metal Injection Molding) is a manufacturing technology that combines the shape making complexity of Plastic

Injection Molding with the material flexibility of Powder Metallurgy.

Q: Why should use MIM?

A: MIM excels in producing small, highly complex parts that are difficult or cost prohibitive to produce with conventional technologies such as machining or casting.

Q: What do I need for offering a quote?

A: Please offer us 2D or 3D drawings(with material ,dimension,tolerance,surface treatment and other technical requirement etc.) quantity ,application or samples. Then we will quote the best price within 24h.

Q: How does MIM differ from the Traditional PM process?

A: Tradition PM uses high, uniaxially applied pressure to coarse metal powders in a die set to produce moderately complex components. MIM products are not limited in shape complexity due to the flexibility of the injection molding process. The fine metal powders used -combine with higher sintering temperatures to allow MIM to achieve near full density in the final article.This allows MIM products to have similar properties as wrought materials.

Похожие товары

Металлические части корпуса литья под давлением

US $0.25-$0.75

Запасные части для литья под давлением

US $0.67-$5.00

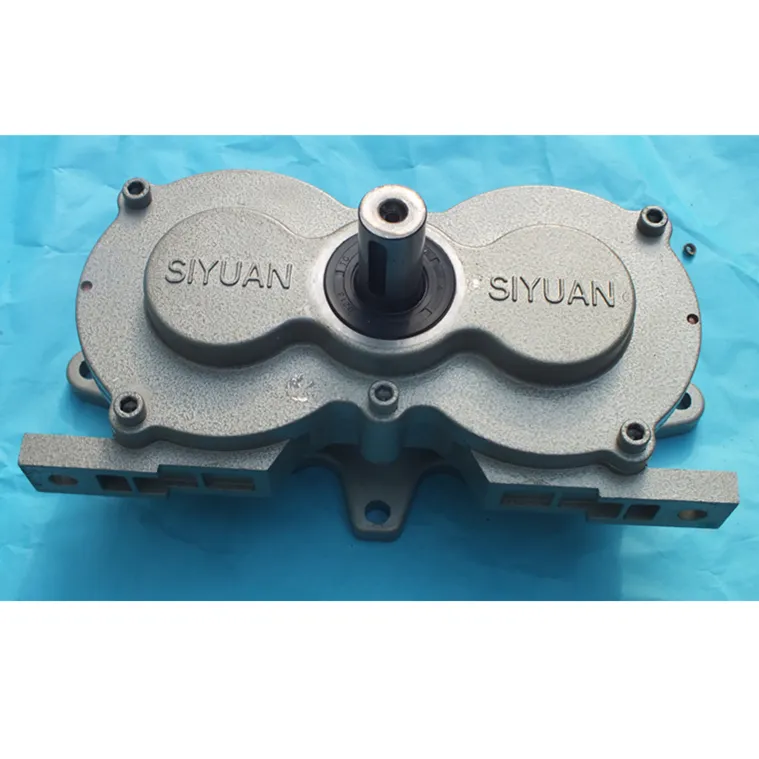

Мягкая машина для мороженого запчасть блендер конус рамка редуктор

US $1.00-$128.00