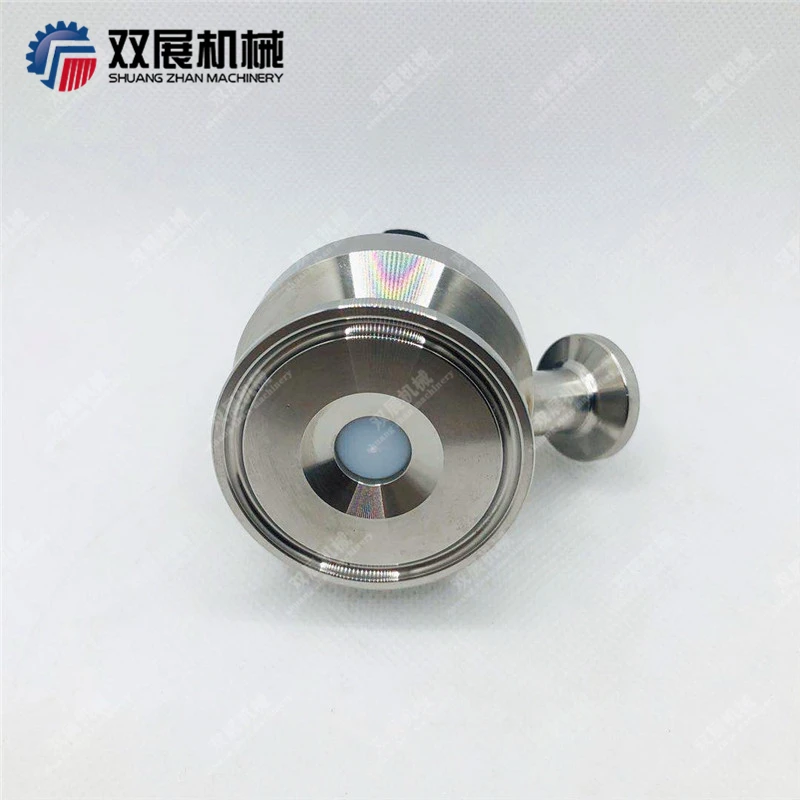

Трехзажимный гигиенический клапан для образцов 1 5 дюйма с одним шлангом и заглушкой aisi316

- Категория: Needle Valves >>>

- Поставщик: Wenzhou,Shuangzhan,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.92 $* | 0.87 $* |

| Aug-15-2025 | 0.91 $* | 0.66 $* |

| Jul-15-2025 | 0.93 $* | 0.68 $* |

| Jun-15-2025 | 0.0 $* | 0.26 $* |

| May-15-2025 | 0.2 $* | 0.72 $* |

| Apr-15-2025 | 0.97 $* | 0.98 $* |

| Mar-15-2025 | 0.83 $* | 0.38 $* |

| Feb-15-2025 | 0.86 $* | 0.48 $* |

| Jan-15-2025 | 0.33 $* | 0.30 $* |

Характеристики

aspetic ferrule ends sampling valve

---We use great PTFE material as seal, excellent Tensile Elongation

Sanitary sampling valves are primarily used for material sample collection in tank equipment or piping and require sterilization prior to and after each sampling. No dead ends, complete sterilization, continuous sampling and sterile sampling at any time. Widely used in food, wine, beverage, dairy products, toothpaste cosmetics, bio-pharmaceutical and other industries.

Product Description

Technical Parameters

◆Specifications: 50.5mm or 25.2mm ferrule ends, 1.984" 0.984”

◆Connection method: welding

◆Maximum working pressure: ≤8bar

◆Maximum sterilization pressure: ≤3bar

◆Working temperature: -10 ° C to 120 ° C

◆Maximum sterilization temperature: 120~180°C

◆Contact with material: SS316L

◆Internal surface contact product: Ra≤0.8μm

◆Sealing: SILICON/EPDM/PTFE

◆Connection method: welding

◆Maximum working pressure: ≤8bar

◆Maximum sterilization pressure: ≤3bar

◆Working temperature: -10 ° C to 120 ° C

◆Maximum sterilization temperature: 120~180°C

◆Contact with material: SS316L

◆Internal surface contact product: Ra≤0.8μm

◆Sealing: SILICON/EPDM/PTFE

working principle

This aseptic sampling valve is mainly divided into hand wheel, bracket, valve core, spring, valve body, diaphragm seal ring. When in the closed state, rely on turning the handwheel counterclockwise to loosen the valve core (until the handwheel is in the neutral position), and the sealing rubber head is pressed by the valve core to the inlet of the valve body material to achieve the sealing effect; if sampling is required, Vapor or other sterilizing medium is introduced from one of the (usually the lower) sampling ports, and the entire sample chamber is filled and discharged from the other sampling port. After a certain period of time, the sample chamber and the sampling port are sterilized; By rotating the hand wheel clockwise, the valve core is pulled, so that the sealing rubber head is detached from the inlet of the valve body material, so that the sample flows out of the tank through the sample chamber and is collected from the sampling port; after the sampling is completed, the hand wheel is rotated counterclockwise. Relax the valve core, and press the sealant head to the inlet of the valve body through the valve core again; pass the clean water to drain the residual liquid in the sample chamber. (If the sample is a clean medium such as sterile water, this step can be Omitted), then inject the sterilizing medium to seal and keep it for the next sampling.

This aseptic sampling valve is mainly divided into hand wheel, bracket, valve core, spring, valve body, diaphragm seal ring. When in the closed state, rely on turning the handwheel counterclockwise to loosen the valve core (until the handwheel is in the neutral position), and the sealing rubber head is pressed by the valve core to the inlet of the valve body material to achieve the sealing effect; if sampling is required, Vapor or other sterilizing medium is introduced from one of the (usually the lower) sampling ports, and the entire sample chamber is filled and discharged from the other sampling port. After a certain period of time, the sample chamber and the sampling port are sterilized; By rotating the hand wheel clockwise, the valve core is pulled, so that the sealing rubber head is detached from the inlet of the valve body material, so that the sample flows out of the tank through the sample chamber and is collected from the sampling port; after the sampling is completed, the hand wheel is rotated counterclockwise. Relax the valve core, and press the sealant head to the inlet of the valve body through the valve core again; pass the clean water to drain the residual liquid in the sample chamber. (If the sample is a clean medium such as sterile water, this step can be Omitted), then inject the sterilizing medium to seal and keep it for the next sampling.

Dimensions

1. PTFE sealing

2. single hose type, but dimensions is the same

working

Left: Sampling state diagram

Right: Sterilization state diagram

Packing&Shipping

bubble bag-carton

Company Introduction

Shuangzhan Machinery (new tek) is a growing factory which focus on developing high quality, intelligent, sanitary valves, equipments used in beverage and dairy field, sanitary pumps, sanitary pipe fittings, and a variety of fluid engineering applications. The products are widely used in wine, food, beverage, pharmaceutical, biopharmaceutical, water treatment, fine chemicals and other industrial fields.

website | www.brewingtanks.com |