2021 новая конкурентоспособная цена производственная линия кассавы

- Категория: Мельница >>>

- Поставщик: Nanyang,Goodway,Machinery,&,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 17255.48 $* | 18118.29 $* |

| Aug-17-2025 | 17110.81 $* | 17966.70 $* |

| Jul-17-2025 | 14355.22 $* | 15073.27 $* |

| Jun-17-2025 | 16820.86 $* | 17661.18 $* |

| May-17-2025 | 14645.29 $* | 15377.55 $* |

| Apr-17-2025 | 16530.56 $* | 17357.84 $* |

| Mar-17-2025 | 16385.7 $* | 17204.25 $* |

| Feb-17-2025 | 16240.89 $* | 17052.15 $* |

| Jan-17-2025 | 16095.67 $* | 16900.12 $* |

Характеристики

Introduction of Garri processing line

Garri is a popular West African food, which is made from cassava tubers.

We make garri mainly by peeling, washing, grinding or crushing through cassava tubers to produce cassava slag. The cassava residue is placed in a bag and the cassava residue is fermented for one or two days, and the water contained in the cassava residue is squeezed out by a hydraulic press. The cassava pressed into a block can be pulverized into a powder by a grinder. The garri powder can be obtained by frying the garri powder through the frying machine. The processed garri can be directly packaged by the packing machine, so that the processed garri powder can be stored for a long time

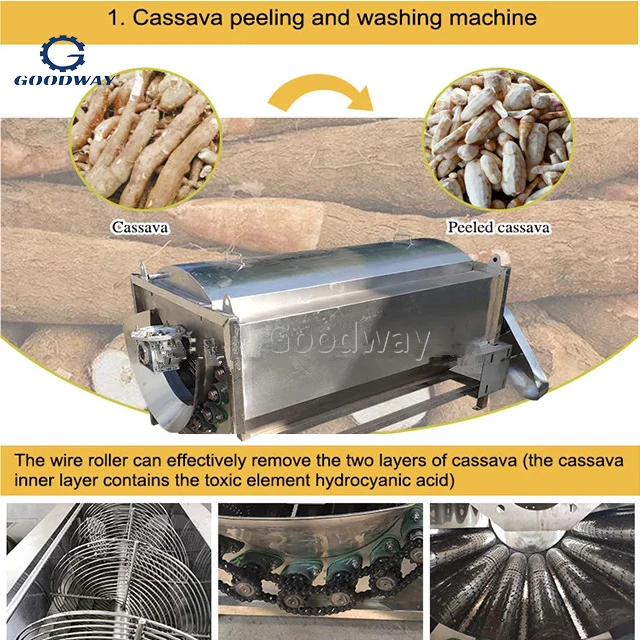

1. Cassava peeling and washing machine

Cassava cleaning and peeling machines are mainly used to clean and remove the skin on the surface of cassava. The peeling machine can reduce waste, save time and manpower, and can clean and peel the cassava in a short time; the cleaning and peeling machine can process 1t/h cassava, while the manual peeling can only process 20kg/h.

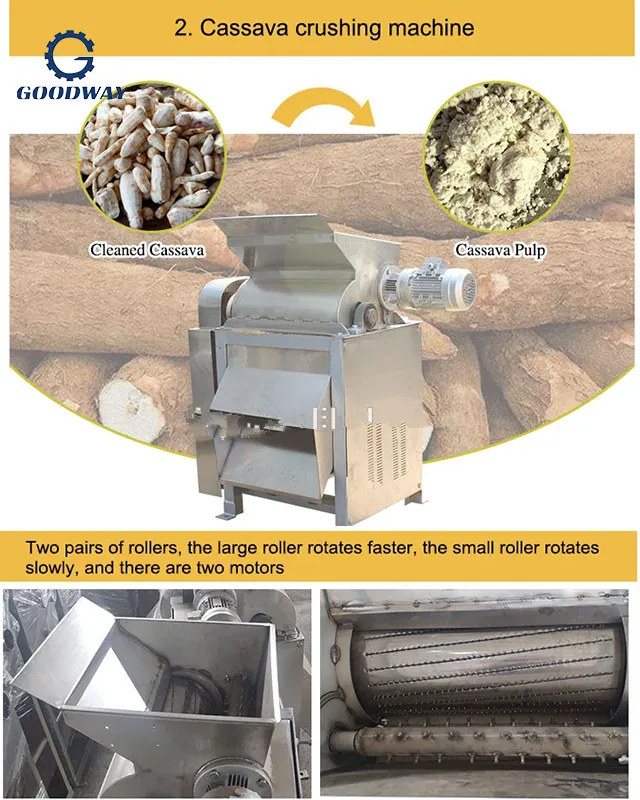

2. Cassava crushing machine

The main function of the cassava crushing machine is to crush the peeled and washed cassava tubers into slag and pulp, then the cassava slag can be used directly for dewatering. Cassava crushing machine can process cassava 1t/h.

3. Cassava hydraulic dehydrator

The hydraulic dehydrator is the third step in the garri processing line. After the cassava slag enters the machine, the machine uses the hydraulic principle to squeeze out the moisture in the cassava after crushing. It is especially suitable for small production. The parts of the equipment that come into contact with the raw materials are made of stainless steel, which ensures the quality of our machines.

4. Cassava milling machine

The milling machine mainly pulverizes the dehydrated and fermented cassava into powder, and the fineness of the grinder garri powder is determined by the pore size of sieve. The user can reasonably select the screen according to the granularity requirements of garri powder.

5. Garri frying machine

Garri frying machine is the fifth step in processing of garri processing line. Frying machine can automatically stir fry and control the temperature of the equipment. It is mainly used for the processing of cassavagarrihydraulic presss. Frying machine mainly consists of pan, frame, stirring part, heating part, driving part, discharge part and others. Frying machine is made of stainless steel, and the machine has the features of heating fast, even and temperature stable, and can prevent pasting phenomenon.

6. Sieving machine

The sieving machine is mainly sifted out of different sizes of garri powder, and a total of three different sized particles can be sieved. Larger particles can be milled again through the milling machine.

Machine stock

Nanyang Goodway Machinery & Equipment Co., Ltd. is a leading manufacturer and supplier of Cassava & Potato Processing Machineries, focus on providing the system solutions in the fields of Cassava Starch, Potato Starch, Sweet Potato Starch, Cassava and Yam Flour, Garri/Gari, Fufu Flour, Cassava Chips processing since 1991 in the worldwide. Presently, most of our managers are technical and marketing experts, including more than 100 mechanical engineers, they are major in mechanical equipment and many years experienced in mechanical equipment manufacturing, research and development. So far Goodway has acquired 35 national patents in the field of cassava & potato processing machinery. Meanwhile, we cooperate with many high technology partners and Institutes, as well as many professional Universities all the time. In order to provide high quality products and services, Goodway adopts the advanced mechanical production line and internal management system, with the international standards as development objectives, pass the ISO9001:2015 certificate of quality system, ensuring all products delivered are 100% qualified. Materials and finished goods are inspected in strict compliance with standards. Goodway carries out a multiple stage quality management system: Incoming Quality Control(IQC), In-process Quality Control(IPQC), and Outgoing Quality Control(OQC). After-sales technical support and service for our customers. So far, the products of Goodway have been sold to more than 50 countries and areas, including Africa, South America, Middle Asia, East Europe and Southeast Asia, etc. And the growing trend still keeps at high speed with our better R&D, quality and service, we will try our best to supply better and better mechanical equipment solutions to satisfy our customers all over the world.

Pre-sale service

1. Introducing detail features and application of the products to customer.

2. Selecting economical and practical machines for customer.

3. Providing operation data of the related machine.

4. Providing means of trial performance for customer.

5. Flow chart and factory designing layout .

Sale service

1. Recommending engineering conditions required for installation of the machine.

2. Communicating the manufacturing progress of machines with customer in time.

3. Project planning and design services.

After-sale service

1. Training of equipment maintenance and operating personally.

2.Installation and commissioning of equipment until everything is functional.

3. One year warranty and Providing long-term maintenance service and spare parts.

4. Giving technical support to customer for developing new product.

5. Engineers available to service machinery overseas.

6. Provide English Version of Installation/Operation/Service/Maintenance Manual