3 станции холдная ковка гайки и болты делая машину

- Категория: Кузнечное оборудование для металла >>>

- Поставщик: Wenzhou,Zhanfan,International,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.13 $* | 0.62 $* |

| Aug-20-2025 | 0.99 $* | 0.1 $* |

| Jul-20-2025 | 0.16 $* | 0.24 $* |

| Jun-20-2025 | 0.57 $* | 0.26 $* |

| May-20-2025 | 0.54 $* | 0.60 $* |

| Apr-20-2025 | 0.27 $* | 0.69 $* |

| Mar-20-2025 | 0.73 $* | 0.26 $* |

| Feb-20-2025 | 0.42 $* | 0.99 $* |

| Jan-20-2025 | 0.7 $* | 0.36 $* |

Характеристики

Product Description

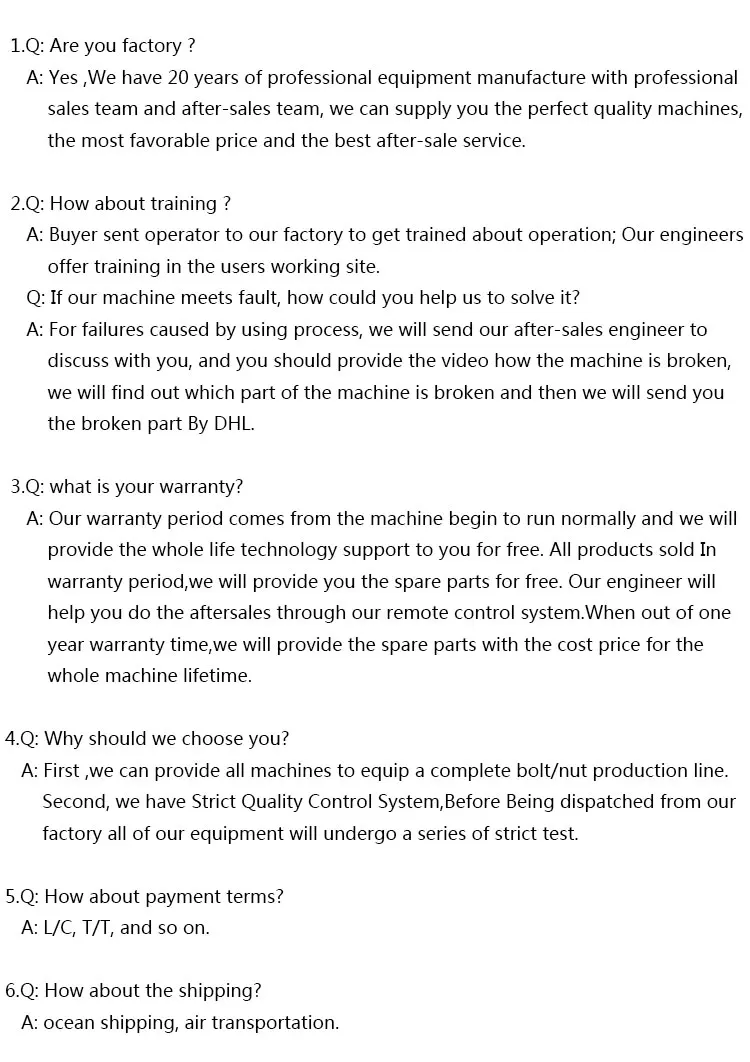

3 Station cold forging bolt maker BF-41B is a specialized machine tool with high efficency and automation among forging machinery. Cold forging formers are used as an important means for producing different kinds of bolts, screws, rivets and nuts in the field of fastener industry. The formers are also widely used in different national economic territories for producing fasteners and abnormal non-standard parts such as aviation,steamer,machinery,rail traffic, vehicle,motorcycle,bicycle,sewing machine, construction,furniture, light industry and daily necessities, etc.

| Condition | New |

| Place of Origin | Zhejiang, China |

| Brand Name | Zhanfan |

| Model Number | BF-41B |

| Certification | CE |

| Forging Station | 3 |

| Cut-off dia. (max) | 36mm |

| Cut-off length (max) | 400mm |

| P.K.O Length | 60mm |

| Main Slide stroke | 500mm |

| Forging force | 450T |

| Main Motor | 112kw |

| Die pitch(mm) | 195 |

| Main die size | D178*L385mm |

| Weight | 124T |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Warranty | 1 year |

| Packaging Details | Wooden pallet/ container |

| Port | SHANGHAI ,NINGBO |

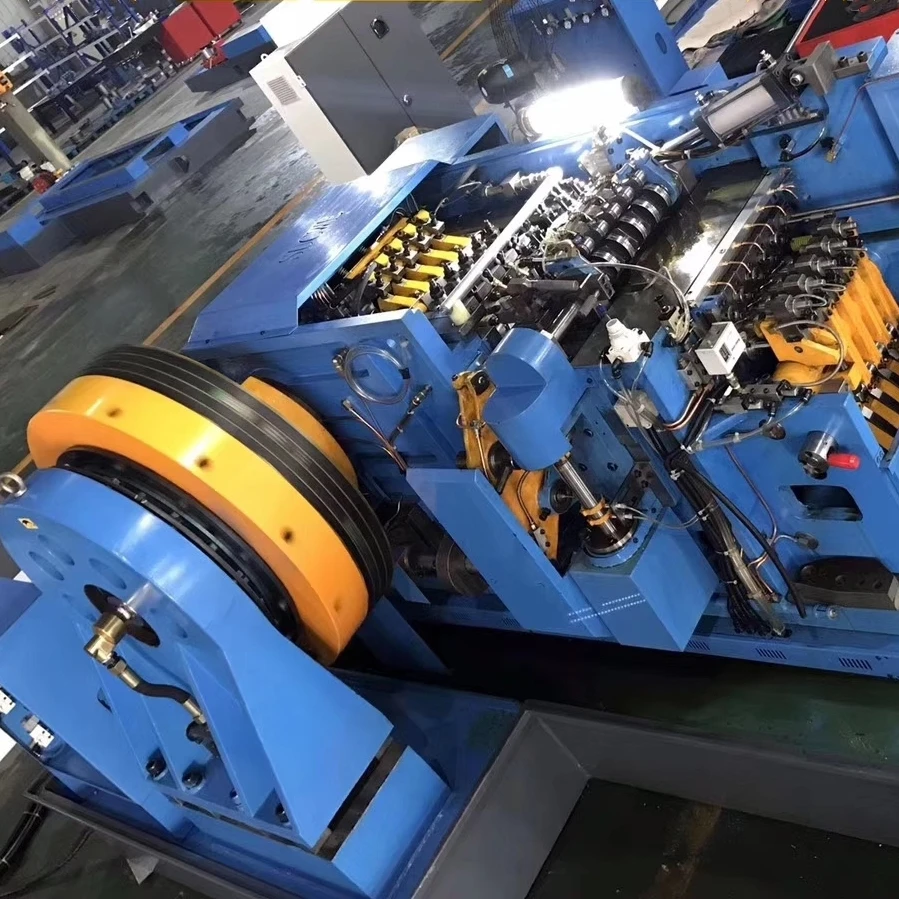

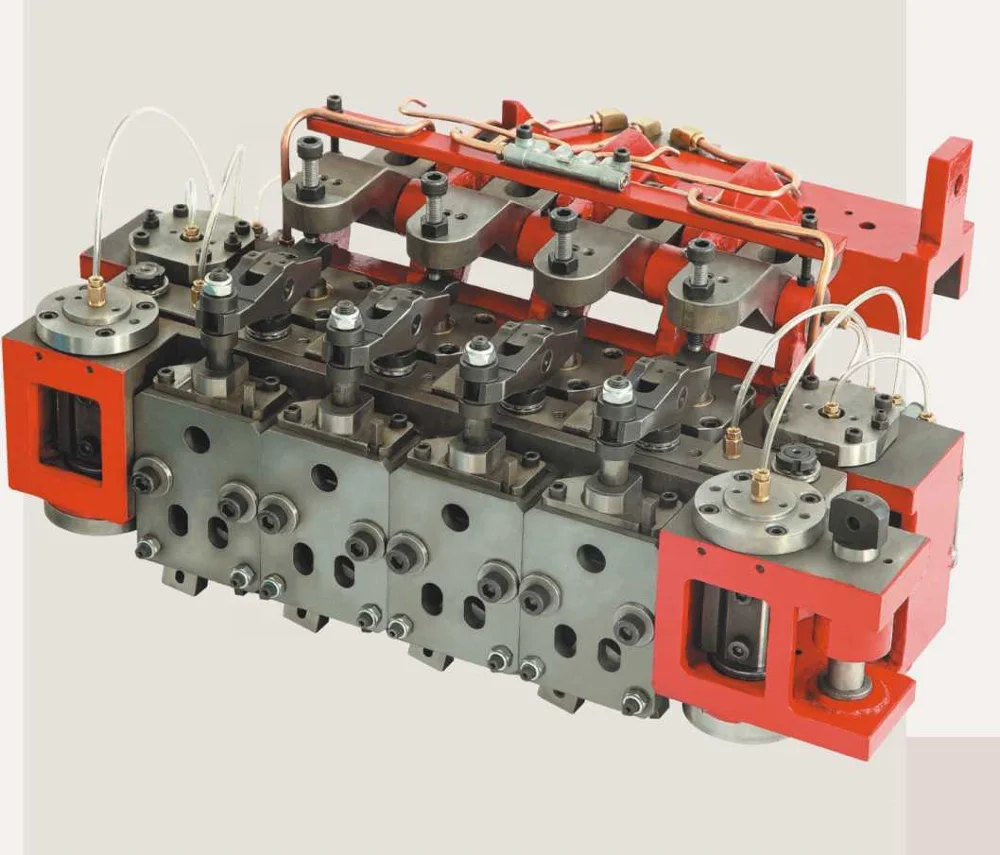

Product Show

Feature

1. Insert oil-free self-lubricating bearing, improve the life and wear resistance of connection shaft, and reduce energy consumption.

2, the circuit system for the inverter plus PLC, not only can be infinitely variable, but also can automatically detect the fault state of the machine work stop.

3. Air pressure pneumatic clutch is adopted, the starting current is small, the brake is stable, and the stop slider can stop to the rear dead point every time except the inching mode, providing the maximum operating space.

4. Design and develop the closed protective cover to greatly reduce the pollution of hot oil and gas mist to the working environment.

5. The machine is equipped with pressure protection device for oil line to ensure sufficient lubrication of all parts during the operation of the machine.Air pressure protection device is set to protect the machine overload and improve the service life of the mold.

6. While making sure the machine is convenient for debugging, safety protection doors are set in many places to emphasize the standard operation of operators and ensure their safety.

2, the circuit system for the inverter plus PLC, not only can be infinitely variable, but also can automatically detect the fault state of the machine work stop.

3. Air pressure pneumatic clutch is adopted, the starting current is small, the brake is stable, and the stop slider can stop to the rear dead point every time except the inching mode, providing the maximum operating space.

4. Design and develop the closed protective cover to greatly reduce the pollution of hot oil and gas mist to the working environment.

5. The machine is equipped with pressure protection device for oil line to ensure sufficient lubrication of all parts during the operation of the machine.Air pressure protection device is set to protect the machine overload and improve the service life of the mold.

6. While making sure the machine is convenient for debugging, safety protection doors are set in many places to emphasize the standard operation of operators and ensure their safety.

Company Information

Packaging & Shipping

![LG]BH4(R5X}VBGQ43}AM1_S](http://sc01.alicdn.com/kf/Heef45767d95f44dcbb35d727ca1a5d3cr/240536791/Heef45767d95f44dcbb35d727ca1a5d3cr.png)

FAQ