VPD-250 автоматическая машина для влажных салфеток чайник и

- Категория: >>>

- Поставщик: Hunan,Grand,International,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.91 $* | 0.90 $* |

| Aug-18-2025 | 0.34 $* | 0.44 $* |

| Jul-18-2025 | 0.23 $* | 0.53 $* |

| Jun-18-2025 | 0.99 $* | 0.42 $* |

| May-18-2025 | 0.90 $* | 0.69 $* |

| Apr-18-2025 | 0.64 $* | 0.59 $* |

| Mar-18-2025 | 0.23 $* | 0.61 $* |

| Feb-18-2025 | 0.79 $* | 0.87 $* |

| Jan-18-2025 | 0.62 $* | 0.22 $* |

Характеристики

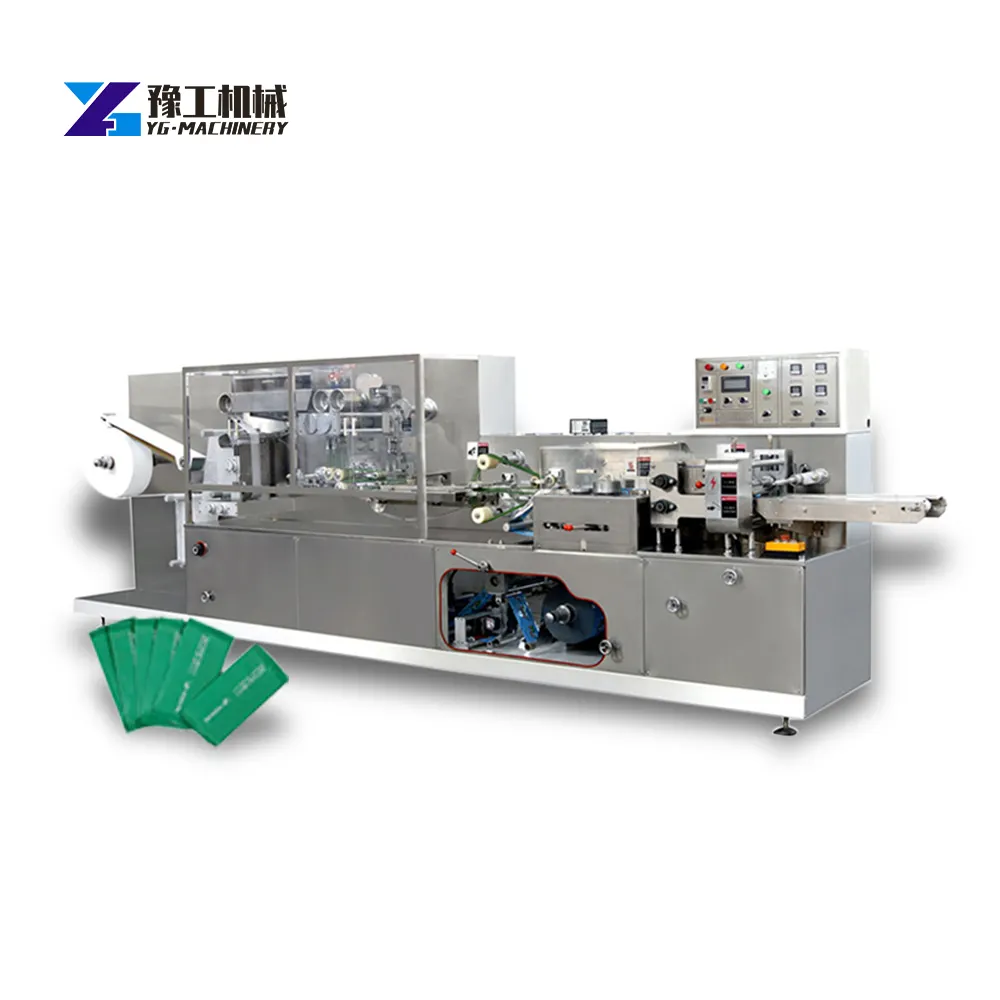

VPD-250 Auto Wet Tissue Maker and Packer Wet Wipes Packing Machine Factory

Item/Model | Model: VPD-250 |

| ||

For Alcohol Pad | For Wet Wipes |

| ||

Packaging Form | Horizontal four-side sealing | |||

Packing Material | CPP, PE, BOPP CPP film, PE film, BOPP film | |||

Wet Tissue Material | 40-80g/m2 air laid paper, non-woven, spun lace non-woven fabric etc. | |||

Folding Way | Max. 10 folding vertical, and 4 folding horizontal | |||

Packing Specification | Length | 30mm-50mm | 50mm-125mm | 80mm-175mm (special design max 220mm) |

Width | 40mm -110mm | |||

Max. Size | L50mm×W50mm | L120mm×W110mm | ||

Packing Speed | 120-160bags/minute | 60-120 bags/minute | 60-100 bags/minute | |

Liquid added Range | 0-10ml [precision ±0.5ml ;the coefficient of viscosity should under the 20000(cp)] | |||

Total Power | 2.8KW | |||

Power Supply Type | Single phase two wire 220V 50/60Hz | |||

Machine Noise | ≤64.9dB(A) | |||

Air Supply | 0.6-1.0 MPa | |||

Air Consumption | 300-500L/min (w-1.0/10 air compression machine is needed) | |||

Machine Dimension | L2800×W1080×H1800mm | L2800×W2800×H1800mm | L3000×W2800×H1800mm | |

Machine Weight | 1000KG | 1100KG | 1300KG | |

We make design of the machine according to the world advanced paper and non-woven packaging machinery technology, our wet wipes packing machine is suitable for the manufacture of moist towelettes in any size and Packaging. But it need to changed the different heater platens for manufacture different size moist towelettes , so good communication is the first step to letting us know which type wet wipes or what’s the size of the wet wipes you are preparing to produce.

Main Performance and Structural Features

1. The machine work steadily and continuously, it is suitable for four-side sealing products of all types wet wipes/tissue, alcohol swabs/pad and so on.

2. Single bag or two bags in row can be set freely (max. four bags in row for alcohol swabs).

3. Full automatic pouch forming, photo electricity correction, no blank edge and fault forming.

4. The tissue can be folded in different types. Max 8 folding vertical, and 4 folding horizontal, fold freely by unfold non-woven width, length.

5. Adopts Japan imported spray pump, make it accurate adding with tolerance of 0.01ml/time. Many kinds of liquid are available. It can add per liquid per bag or add all the liquid in the same bag.

6. Double times sealing better to ensure the liquid adding volume and avoid leaking.

7. The machine is easy to operate, PLC touch panel, could adjust the packing temperature and speed according to the packing material, product's thickness and length, servo motor, controlled by light, electric and air power, failures can be self- diagnosed and displays clearly. The language of operate system can be made in your local language as Spanish, French, Korean, Russian, Japanese, Arabic and so on.

8. The full machine is covered with stainless steel in good appearance, also easy to clear and durable. Low operation and maintenance cost.

9. The confined glass cover, to avoid contamination, less noise.

10. The sealing mold is made by aluminum alloy, have a very high thermal shock resistance, do not thermal deformation.

1 | Package film install unit | 2 | |

3 | 4 | Bag forming unit & Color code tracking mechanism | |

5 | 6 | Tissue insert and liquid adding unit | |

7 | 8 | Tissue cutting unit | |

10 | PLC and touch screen controller | ||

11 | Traction roller | 12 | Cutting unit |

13 | Folding tissue frame | 14 | Tissue roll unit |

Service 1

Providing photographer recording high precision video about installing, debugging and changing mould for you before shipment, cost paid by ourselves. The video helps you operate the machine better, which not provided by other suppliers.

Service 2

Different languages are available to be inputted in the touch screen, such as Russian, Arabic, French, Spanish etc., in order to help your machine operator understand and run machine smoothly.

Service 3

We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4

12 (twelve) months guarantee time. During this Warranty period, we will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice. We will also provide one set of spare parts/wear & tear parts to customer along with the shipment of the machine.

Service 5

Warmly welcome suggestions from customer, to help us grow better and provide much better machines. Meanwhile, welcome to have a visit or inspection the machine before order or shipping. We'll arrange the pick up and your following schedule in our city to bring you a nice journey.

Hunan Grand Packing Machinery Co., Ltd.

We're specialized in the pharmaceutical and packing machiney for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc..

Our machines were exported to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea, the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago, Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. Good reputation of the machine quality and after sales service always gained from customers. Various kinds of factories and companies in different fields are cooperating with us. Such as pharmaceutical, food , supplement, stationery, hardware, agrochemical factories. For pesticide, fertilizer, personal care products, like cosmetics, daily use products etc..

Our sales team are professional in communicating with customer about different aspects of our machines. We also have our own technical research group to do the new products development and professional group for customer overseas after sales service . For customer who doesn’t need our enginner for machine installation, we will provide them the detail and professional machine installation and running video for support and help.

Welcome to get in touch with us, we are always here for you...