Аппарат для смешивания компоста на органических

- Категория: Compost Making Machines >>>

- Поставщик: Harbin,Dadi,Biology,Organic,Fertilizer,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 265280.40 $* | 278544.29 $* |

| Aug-18-2025 | 263050.68 $* | 276203.51 $* |

| Jul-18-2025 | 220695.57 $* | 231730.46 $* |

| Jun-18-2025 | 258592.84 $* | 271522.84 $* |

| May-18-2025 | 225153.70 $* | 236411.54 $* |

| Apr-18-2025 | 254133.55 $* | 266840.61 $* |

| Mar-18-2025 | 251904.15 $* | 264499.36 $* |

| Feb-18-2025 | 249675.64 $* | 262159.16 $* |

| Jan-18-2025 | 247446.71 $* | 259818.88 $* |

Характеристики

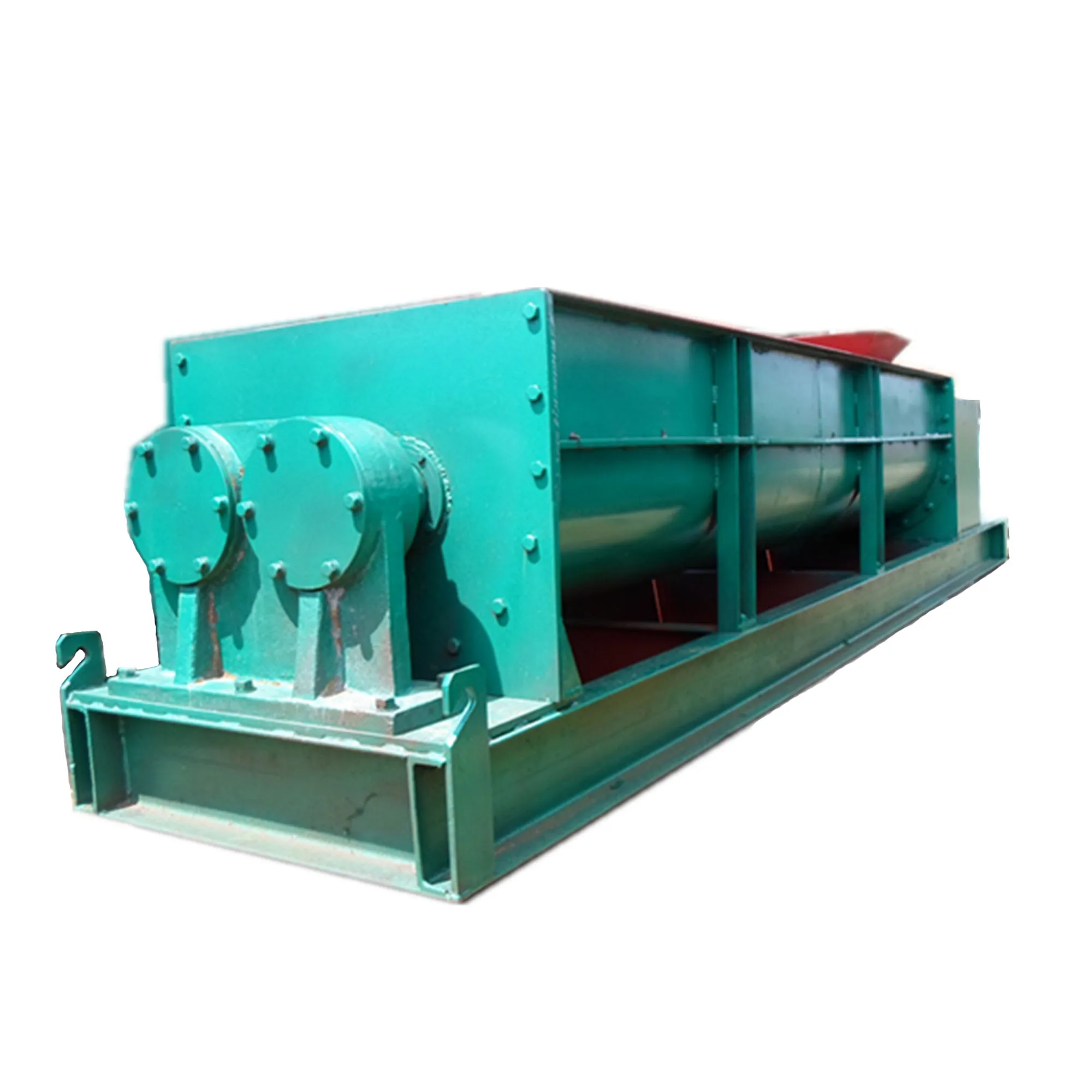

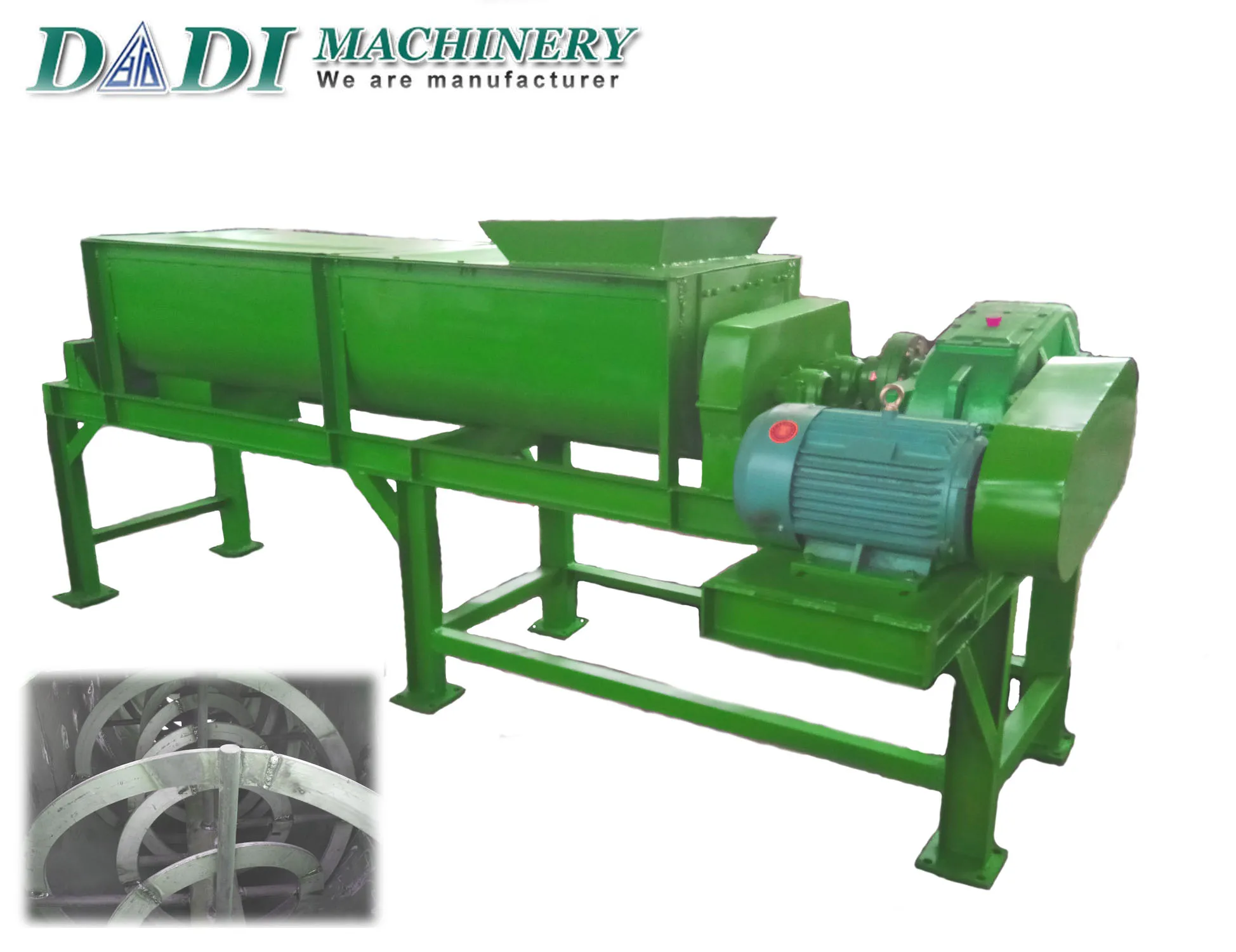

Compost mixing machine in organic fertilizer plant

Capacity:1-8 Tons per hour Compost mixing machine

The raw materials for fertilizer granulation should be mixed evenly after batching according to the formula, so raw material mixer equipment is an essential component in the production of organic fertilizer. As usual the single shaft horizontal mixer used for compound fertilizer (organic materials add chemical / mineral raw materials) , and double shaft mixer used for organic raw materials .

Mixer is mainly used to humidify and mix powdery materials in the fertilizer industry. The machine uses shaft(s ) with spiral blades mounted to mix the materials. As the spiral blades have multiple angles, raw materials can be mixed quickly and effectively, regardless of their shape, size and density. The shifts mixer ( blender ) is also suitable for mixing viscous material with about 20%-40% moisture content.

| Model | DSM-1 | DSM-2 | DSM2A | DSM-2B | DSM-3 |

| Capacity: t/h | 1-1.8 | 2-2.5 | 2.5-3.5 | 3.5-6 | 6-8 |

| Revolving speed :r/min | 4 | 4 | 4 | 4 | 4 |

| Power:KW | 7.5 | 15 | 15 | 15 | 22 |

| Size L×W×H:M | 2.5*1.4*0.8 | 3*1.4*1 | 3*1.4*1 | 3.5*1.6*1.1 | 3.5*-1.6*1.1 |

| Weight:KG | 1200 | 2200 | 2200 | 2400 | 2400 |

| Voltage:V | 380 V(it can be change under your need ) | 380 V | 380 V | 380 V | 380 V |

| LCL | FCL | |

| Way | Wooden cases with steel frame | Container |

| Packaging Details | The normal package is wooden box (Size:L*W*H).If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pefilm for packing or pack it according to customers special request. | Loaded into container |

1.You can enjoy drawing design, equipment building, installation and running etc.full one-stop services from us.

2.Pre-sales Service

1) View our Factory.

2) Sample testing support.

3) Design the production line for you.

4) Design factory layout according to your requests and factory size.

5) Proposing the most suitable scheme and equipment for you.

6) Offering comprehensive technical and business consultation services.

3.After-sales Service

1) Fast & Safe Delivery.

2) Providing technical exchanging.

3) Training how to install the machine, how to use the machine and maintain.

4) Engineers available to service machinery overseas.

5) Supply wearing parts and factory drawings needed.

1. Are you manufacturer or trading company?

We are manufacturer.

2.What is the payment terms?

We usually accept T/T.

T/T: 30% in advance as down payment, the balance before delivery.

We take pictures of finished products before delivery.

3.How about price?

We are factory and be able to give you the lowest price than market one.

4. Do you accept customized?

Yes , we have different customer make their own OEM product.So we also can make product as per your requirement.

5. Can I get some samples before place order and how long for a sample?

No. Because our product is big and high price.But we can test your material and send the video to you.

6. How is your shipping?

Shipping by sea.

Worldwide shipping service available

Please contact before order as shipping cost varies time to time.

7. How long is your guarantee?

12 months warranty but except quick wearing parts.

Main products:

Organic fertilizer granulator machine /Organic fertilizer production line

Animal feed pellet machine

Biomass fuel pellet machine

Rotary drum dryer

Rotary drum cooler

Crusher

Grading screen machine

Certification

Похожие товары

Горячая продажа буксируемый Компост Тернер машина

Компост Тернер машина, гриб Компост Тернер машина

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com