Изготовление на заказ по порошковой металлической стойке из углеродистой стали и деталям шестерни в инженерной

- Категория: Metal & Metallurgy Machinery Parts >>>

- Поставщик: Shanghai,United,Metal,Materials,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.33 $* | 0.79 $* |

| Aug-17-2025 | 0.79 $* | 0.25 $* |

| Jul-17-2025 | 0.76 $* | 0.14 $* |

| Jun-17-2025 | 0.55 $* | 0.97 $* |

| May-17-2025 | 0.39 $* | 0.97 $* |

| Apr-17-2025 | 0.5 $* | 0.93 $* |

| Mar-17-2025 | 0.33 $* | 0.19 $* |

| Feb-17-2025 | 0.97 $* | 0.0 $* |

| Jan-17-2025 | 0.1 $* | 0.29 $* |

Характеристики

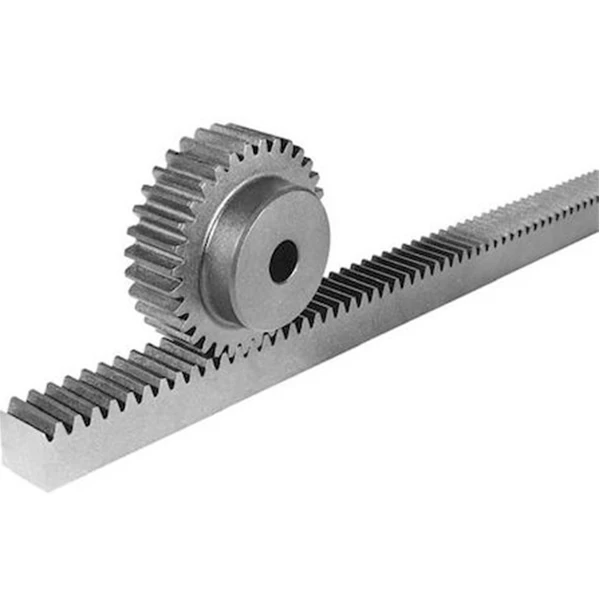

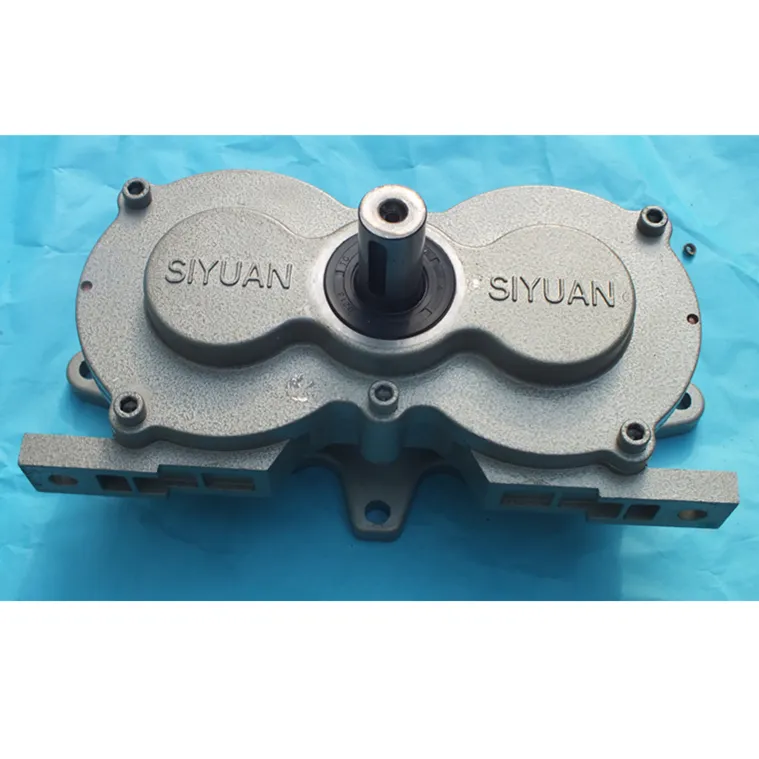

Products Show

Technology/Characteristics | PM | MIM | Machining | Precision casting |

Precision (um) | 0.1 | 0.3~0.5 | <0.1 | 0.5~1.0 |

Density (%) | 88 | 98~99 | 100 | 99 |

Part Weight (Available) (g) | 5~2,500 | 0.01~200 | 1~10,000 | 1~10,000 |

Complexity Level | High | High | High | Medium |

Capacity | High | High | Medium | Medium |

Supply Ability | High | High | Low | Medium |

Mechanical Properties (%) | 70 | >95 | 100 | >95 |

Surface Roughness (Ra um) | 2~5 | 1 | 0.2~4 | 5 |

Characteristics | MIM | Precision Casting |

Hole Diameter (Min.) | 0.4mm | 2mm |

Blind Hole Diameter (2mm) | 20mm | 2mm |

Wall Thickness (Min.) | <1 mm | 2 mm |

Wall Thickness (Max.) | 10 mm | Unlimited |

Tolerance of 4mm Diameter | +/-0.06 mm | +/-0.2 mm |

Surface Roughness | 1 μm | 5 μm |

Materials for MIM

MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc.

Stainless Steel (SS316L/17-4PH/SS304/SS440C)

Iron-Based Alloy (Fe2Ni/Fe4Ni/Fe8Ni)

Typical MIM materials and applications:

Material Item | Composition | Typical Application |

Stainless Steel | 316L,17-4PH, 420, 440C | Medical instruments, watch case and buckle, clocks, IT electronics |

Low Alloy Steel | Fe-2Ni, Fe-8Ni | Automotive, machinery and other industries (particularly in structural components) |

Tool Steel | CrMo4, M2 | Power tools, blade |

Carbide | WC-Co | tools, watches, clocks |

Heavy Alloy | W-Ni-Fe, W-Ni-Cu, W-Cu | 3C communications, The arm industry, counter weight |

Titanium | Ti, Ti-6Al-4V | Medical industry and military structural part |

Magnetic Materials | NdFeB, SmCo, AlNiCo, Ferrite | Magnetic properties of the various components |

Basic properties of main MIM materials

Materials | Brand | Density (g/cm³) | Hardness | Tensile strength (MPa) | Extensibility |

Fe-based Alloys | MIM-3865 (sintered) | 7.65 | 62HRB | 25415 | 25 |

MIM-4750 (sintered) | 7.65 | 100HRB | 600 | 15 | |

Stainless Steel | MIM-316L | 7.85 | 52HRB | 580 | 45 |

MIM-17-4PH | 7.68 | 27HRC | 950 | 15 | |

Tungsten Alloy | 95%W-Ni-Fe | 18.1 | 31HRC | 930 | 10 |

Hard Alloy Carbide | YG8X | 14.9 | 90HRC | Bending strength 2300 MPa | / |

Common-used MIM Products in Different Fields

Aerospace | Aircraft wing chain, Rocket nozzle, Missile tail, Ceramic turbine blade core |

Automotive | Ignition control lock parts, Turbocharger rotor, Valve guide parts, Automotive brake parts, Automotive anti technology backbone parts |

Electronics | Disk drive unit, Cable connector, Electronic housing, Computer print head, Electronic package, Heat sink |

Military | Mines, Rotors, Plates, Triggers, Armor, Hearts, Constellations, Cluster arrows, Small arrows |

Medical | Dental orthodontic brackets, Internal suture needles, Living tissue sampling forceps and Child radiation screen cover |

Machinery | Special milling cutter, Cutting tool, Pinion gear |

Daily Necessities | Watchcase, Watchband, Buckle, Golf tee, Shoe buckle, Sports and sports firearms parts, Document binding punch |

Recommend Products

Why Choose Us

Why Choose BRM

* More than 20 years metal injection molding manufacturing experience

* IATF16949/ISO9001/ISO14001/ISO18001 certification

* Professional sales and service team

* Daily output>200000pcs;5000m2 factory area

* Density after sintering can reach 7.97g/cm3

* Part thinckness can achieve 0.2mm

* Secondary treatment can be finished in-house such as PVD, sand blasting, polish etc.

Factory

Manufacture Equipment

Continuours sintering furnace

Injection Machine

Sizing Workshop

Deburring

Debingding Furnace

Inspection Equipment

3D Measuring instrument

Rheometer

Rockwell Hardmeter

Micro Vickers

SEM Scanning Electron Microscope

Projector

Customers

Certifications

Packing & Delivery

Packaging:

BRM can packing the products with sea or air standards, such as carton, PP bag, wooden case. We can offer OEM service as a professional chinese supplier.

Step 1. The goods were well wrapped in plastic to keep surface perfect.

Step 2. Then they're put in suitable grid in carton and surrounded by copious amounts of soft foam for additional protection.

Step 3. These cartons are packed in firm crates against any shipping-induced trauma.

Step 2. Then they're put in suitable grid in carton and surrounded by copious amounts of soft foam for additional protection.

Step 3. These cartons are packed in firm crates against any shipping-induced trauma.

Delivery

Molding Time (T0) | Sample | Shipping Express |

25 days | 10 days | UPS, FedEx, DHL, TNT |

FAQ

1. What is MIM technology?

MIM (Metal Injection Molding) is a manufacturing technology that combines the shape making complexity of Plastic Injection Molding with the material flexibility of Powder Metallurgy.

2. Is the metal melted in mould during the injection process for the MIM parts?

No. During injection process, only the binder is melted in order to make the metal powders to flow like liquid material. Upon cooling the binders solidify giving the part strength for handling which is called 'Green part'. And green part must be subsequently sintered which can get high density and required mechanical properties. We call it 'Brwon part'.

3. What is the difference between MIM process and Conventional PM parts process?

Conventional PM uses high, uniaxially applied pressure to coarse metal powders in a die set to produce moderately complex components. Typically, no further densification is gained during the sintering process. Densities achieved by this method are typically in the range of 80-90% of theoretical which limit the physical properties that can be achieved for the given alloy. MIM parts are not limited in shape complexity due to the flexibility of the injection molding process. The fine metal powders used - combine with higher sintering temperatures to allow MIM to achieve near full density in the final article approximately near to 99%. It allows MIM parts to have similar properties as given alloy.

4. Will the metal injection molding parts shrink during removal of binders?

No, the size of metal injection parts will be not changed in the debinding process. However, in order to achieve near full density, the part will undergo a size change of up to 20% in sintering process.

5. Why use Metal Injection Molding technology (MIM)?

1). MIM parts (Metal injection molding parts) have an significant advantage in producing small, highly complex metal components. While conventional technologies such as PM, machining or casting can't produce it or its cost is very high.

MIM (Metal Injection Molding) is a manufacturing technology that combines the shape making complexity of Plastic Injection Molding with the material flexibility of Powder Metallurgy.

2. Is the metal melted in mould during the injection process for the MIM parts?

No. During injection process, only the binder is melted in order to make the metal powders to flow like liquid material. Upon cooling the binders solidify giving the part strength for handling which is called 'Green part'. And green part must be subsequently sintered which can get high density and required mechanical properties. We call it 'Brwon part'.

3. What is the difference between MIM process and Conventional PM parts process?

Conventional PM uses high, uniaxially applied pressure to coarse metal powders in a die set to produce moderately complex components. Typically, no further densification is gained during the sintering process. Densities achieved by this method are typically in the range of 80-90% of theoretical which limit the physical properties that can be achieved for the given alloy. MIM parts are not limited in shape complexity due to the flexibility of the injection molding process. The fine metal powders used - combine with higher sintering temperatures to allow MIM to achieve near full density in the final article approximately near to 99%. It allows MIM parts to have similar properties as given alloy.

4. Will the metal injection molding parts shrink during removal of binders?

No, the size of metal injection parts will be not changed in the debinding process. However, in order to achieve near full density, the part will undergo a size change of up to 20% in sintering process.

5. Why use Metal Injection Molding technology (MIM)?

1). MIM parts (Metal injection molding parts) have an significant advantage in producing small, highly complex metal components. While conventional technologies such as PM, machining or casting can't produce it or its cost is very high.

2). Part weight is 1~100g.

3). Part thinckness is thin and need high strength which PM and precision casting can't manufacture.

4). MIM can process those metal parts which PM can't achieve better strength and casting can't meet higher tolerance.

Похожие товары

Металлические части корпуса литья под давлением

US $0.25-$0.75

Запасные части для литья под давлением

US $0.67-$5.00

Мягкая машина для мороженого запчасть блендер конус рамка редуктор

US $1.00-$128.00