SC200/200 33 м/мин 2 т строительный Лифт для

- Категория: >>>

- Поставщик: Dahan,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 35700.5 $* | 37485.1 $* |

| Aug-18-2025 | 35400.73 $* | 37170.82 $* |

| Jul-18-2025 | 29700.40 $* | 31185.80 $* |

| Jun-18-2025 | 34800.53 $* | 36540.87 $* |

| May-18-2025 | 30300.48 $* | 31815.12 $* |

| Apr-18-2025 | 34200.2 $* | 35910.1 $* |

| Mar-18-2025 | 33900.83 $* | 35595.32 $* |

| Feb-18-2025 | 33600.87 $* | 35280.7 $* |

| Jan-18-2025 | 33300.75 $* | 34965.67 $* |

Характеристики

|

SC200/200 33m/min 2T Building Construction Elevator For Construction |

PRODUCT ADVANTAGE:

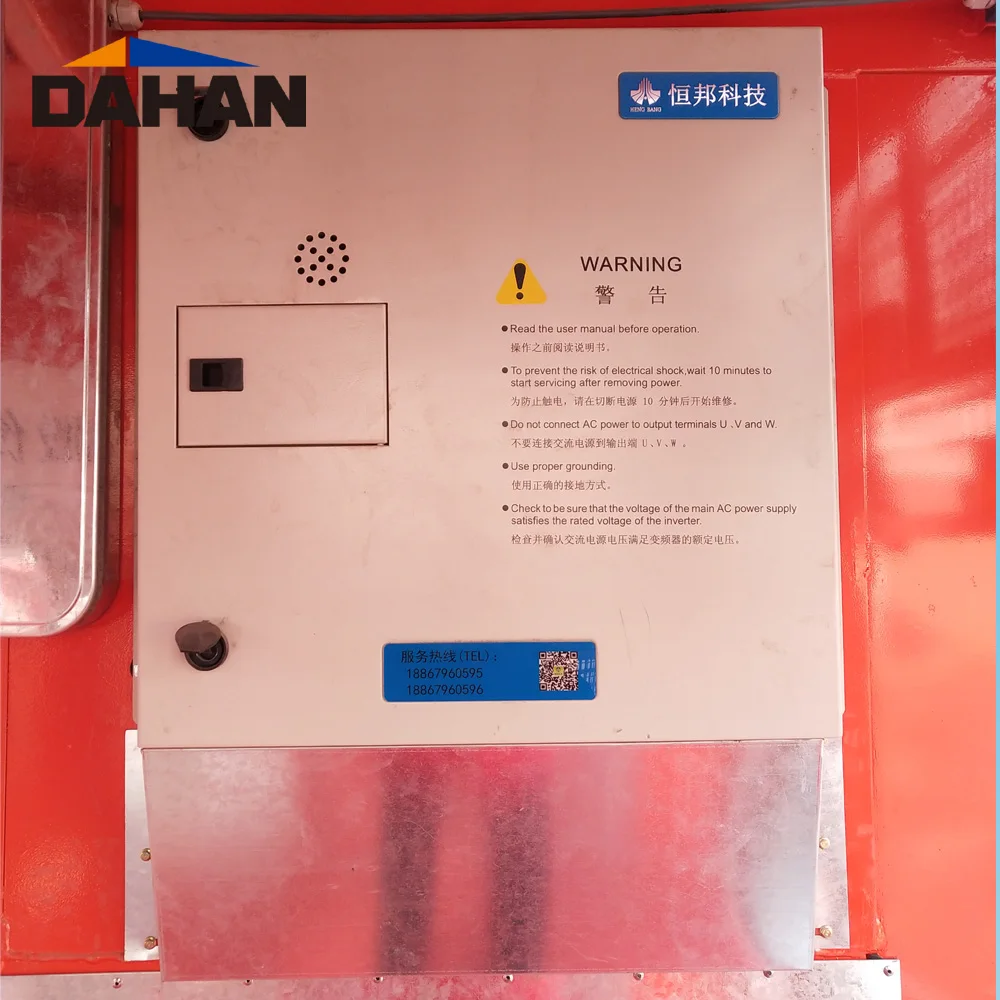

♦ The main electrical components adopt Schneider brand

♦ Each lift has undergone rigorous technical inspection and whole machine test before leaving the factory to ensure the quality.

♦ Frequency speed regulating hoist Smooth running,Energy saving and environmental protection and with long service time.

| No. | Item | Unit | Parameter | Note |

| 1 | Rated Load | kg | 2 x 2000 | Double cage |

| 2 | Install/disassemble Reted load | kg | 2 x 1000 | Double cage |

| 3 | Lifting Speed | m/min | 33 | Reducer Ratio 1:16 |

| 4 | Max. Height | m | 200 | |

| 5 | Cage Dimension(LXW) | m x m | 3x1.5/3.2x1.5 | |

| 6 | Distance Between Foundation And Cage Bottom | m | 0.46 | |

| 7 | Distance between Anchor | m | ≤9 | |

| 8 | Free End Height | m | ≤9 | |

| 9 | Power Supply | V | 380V±5% | |

| 10 | Motor Power | kw | 2x3x11 | JC=25% |

| 11 | Rated Current | A | 2x3x24 | |

| 12 | Safety Device Model | SAJ40-1.2A |

PRODUCT DETAILS

-----------------------------------------

Dahan Technology Co., Ltd.

Construction Hoist:

♦ The main structural parts of the hoist are made of Q355B material.

♦ 36 patented technologies

♦ The main electrical components adopt Schneider brand

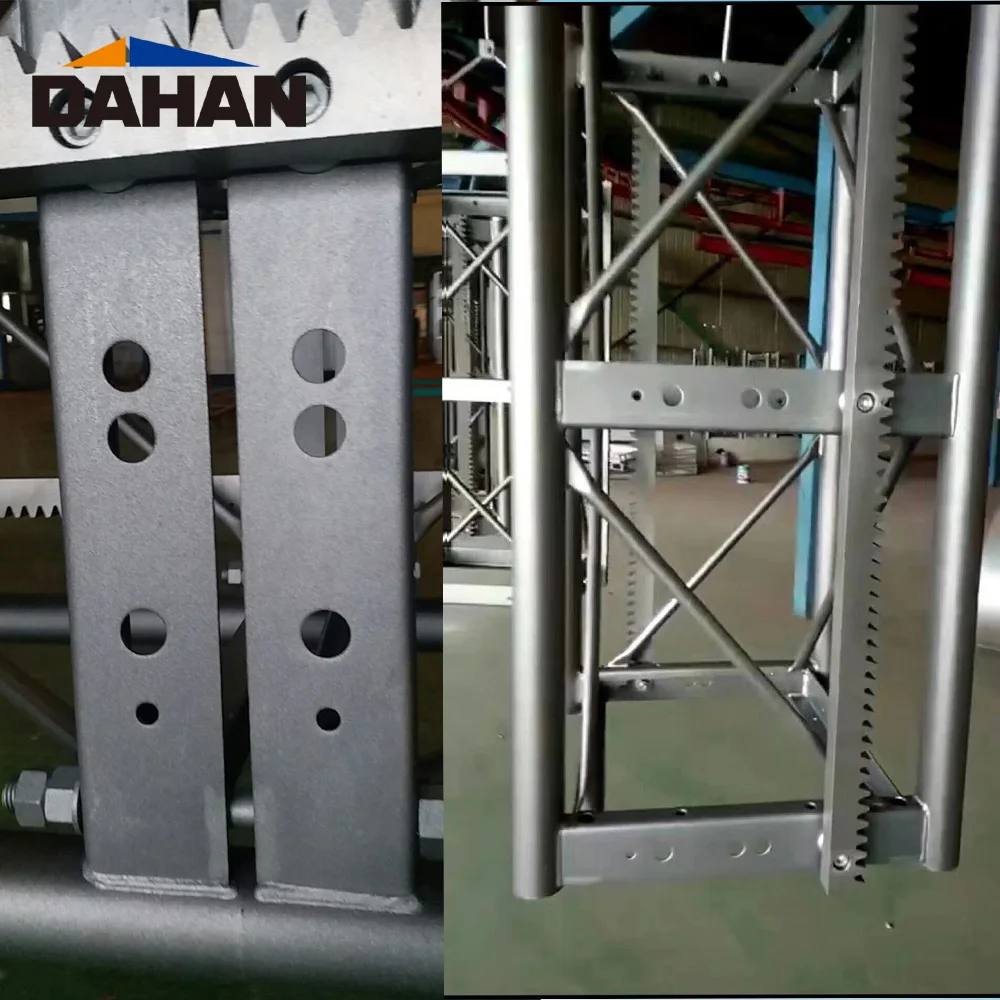

♦ Rack and pinion transmission

| The hoisting cage adopts the overall post-weld processing technology to ensure the precision of the hoisting cage processing. The machine has low noise, low vibration and stable and no impact when the machine is running at high speed. |

| Hanging cage floor adopts FRP grille mesh + galvanized checkered steel plate structure Corrosion resistance, long service life, long-term use of the bottom plate is not easy to deform, especially suitable for use in rainy and humid areas |  |

| The fixed shaft end of the back wheel of the new structure is twice as long as the original structure and the positioning cone pin is increased to improve the stress condition and avoid the back wheel from loosening during use Back wheel structure has been applied for patent, patent number:CN2012864635U |

| Bottom frame and attached wall frame adopts hot-dip galvanizing process |

|

| Increasing the mechanism section, the main section of the mast section is processed with grooves, which can be taken out directly when replacing gears, and the maintenance efficiency is increased by more than 6 times. |

|

PRODUCTION PROCESS

-----------------------------------------

Dahan Technology Co., Ltd.

| ||

| Mast section blanking assembly line: one-time molding using stamping dies to ensure dimensional accuracy and interchangeability of each part of the mast section | Mast section main limb tube blanking and boring processing line: CNC high-speed circular saw and special numerical control equipment are used to ensure the standard section main limb tube length. | |

| ||

| The drive frame adopts the overall post-weld processing technology, which completes drilling, milling, and tapping in one clamping to ensure the machining accuracy of the drive mechanism frame. The machine has low noise, low vibration, and no impact when running at high speed | Mast section main limb tube blanking and boring processing line: CNC high-speed circular saw and special numerical control equipment are used to ensure the standard section main limb tube length. | |

| ||

| The drive frame adopts the overall post-weld processing technology, which completes drilling, milling, and tapping in one clamping to ensure the machining accuracy of the drive mechanism frame. The machine has low noise, low vibration, and no impact when running at high speed | The mast section is shot blasted, washed, degreased, silane, dried, and then sprayed with an automatic spraying process. After drying and curing, cooling and other processes, the product has bright and stable color, good weather resistance and long service life. | |

| ||

| Assemble and install | Debugging | |

PRODUCT APPLICATION

-----------------------------------------

Dahan Technology Co., Ltd.

ABOUT US

-----------------------------------------

Dahan Technology Co., Ltd.

>> Dahan Technology Co., Ltd. is committed to the professional manufacturing of tower cranes and construction hoists. Our firm has manufactured and sold approximately 50 thousand sets of tower cranes and construction lifts. We have been exported to over 50 countries and regions.

>> Our product portfolio comprises 4 main series and over 60 types of products, such as high-top tower cranes, flat-top tower cranes, luffing jib tower cranes and construction hoists. All products come with ISO, CE, and other certificates.

>> Our company proudly employs 2,300 skilled, talented and dedicated workers, including an intelligent and innovative R&D staff of approximately 100 people. Our group now holds 28 national patents and we have participated in the revision of the Chinese national tower crane standard (GB13752).

>> Our materials from big companies as Baosteel, Schneider, and others. All materials go through appearance testing, tensile testing and other serials testing.

>> Our firm is the first to introduce welding robots to tower crane industry in China, We own the most advanced shot blasting and paint spraying line in the world

>> Both the CNC plasma panel cutting machine and CNC profile sawing machine provide high cutting performance which are precise to less than 1mm. Adopting 80% argon and 20% carbon dioxide as welding gas to make the welding quality more stable than before.

>> Transforming from a product supplier to a value-added service provider, we are dedicated to creating the top Chinese brand of tower cranes and becoming a globally competitive and specialized tower crane manufacturer. We are confident we can be your best choice!

more >>

FAQ

-----------------------------------------

Dahan Technology Co., Ltd.

Q : Are you trading company or manufacturer?

A: We are factory

Q : How about the installation?

A: We can send one engineer to your site for installing and inspect

Q: How long is your delivery time?

A : Generally 7 -15 days after advance payment.

Q : 4.How many countries have you been send?

A : About 30 countries.

If you have another question, pls feel free to contact us as below: