MS-3012HD Козловой Пламени и плазменной резки с

- Категория: Оборудование для резки металла >>>

- Поставщик: Changzhou,Heavth,Science,&,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 8806.48 $* | 9246.61 $* |

| Aug-17-2025 | 8732.83 $* | 9169.95 $* |

| Jul-17-2025 | 7326.38 $* | 7692.3 $* |

| Jun-17-2025 | 8584.69 $* | 9013.12 $* |

| May-17-2025 | 7474.11 $* | 7848.2 $* |

| Apr-17-2025 | 8436.54 $* | 8858.63 $* |

| Mar-17-2025 | 8362.44 $* | 8780.88 $* |

| Feb-17-2025 | 8288.75 $* | 8702.29 $* |

| Jan-17-2025 | 8214.48 $* | 8625.10 $* |

Характеристики

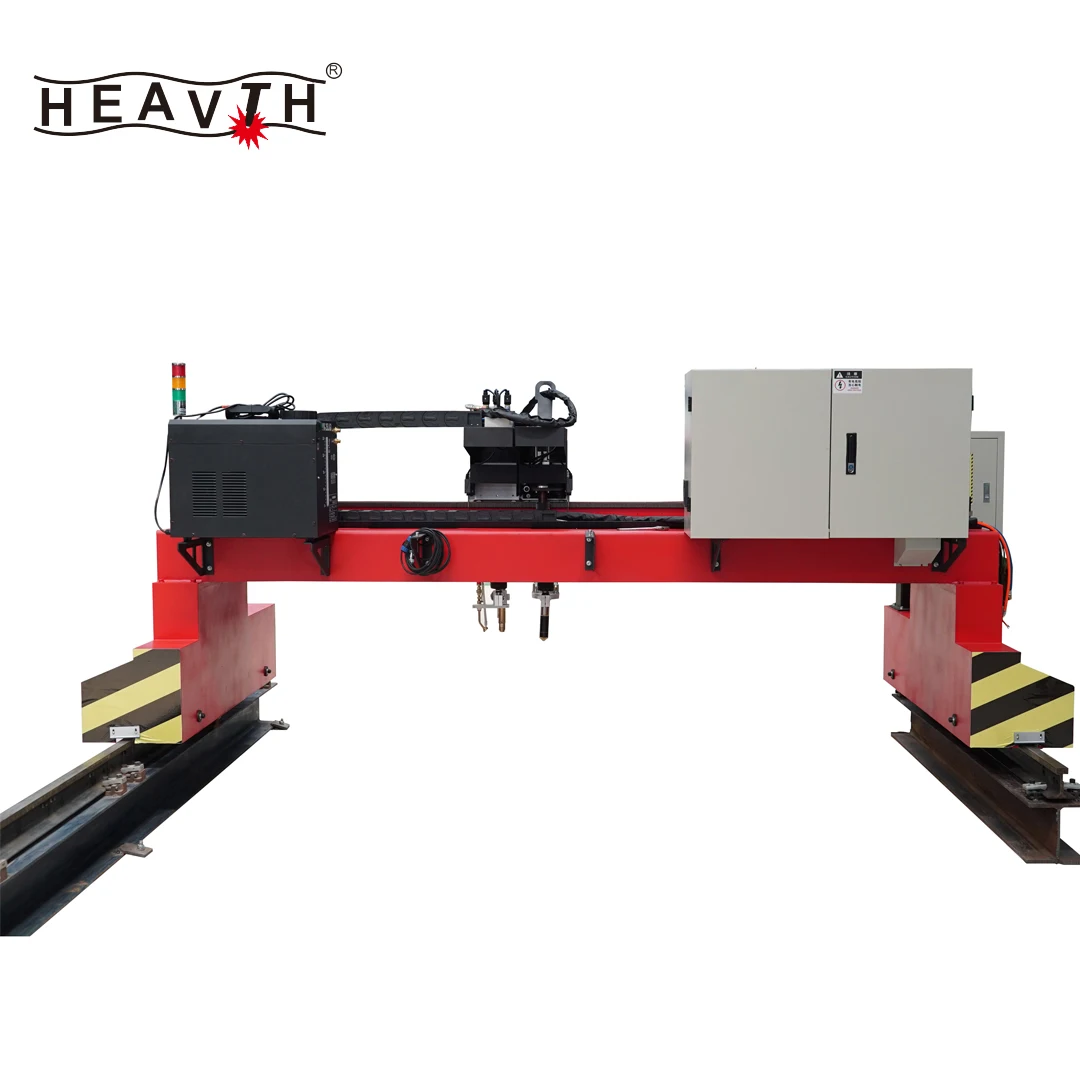

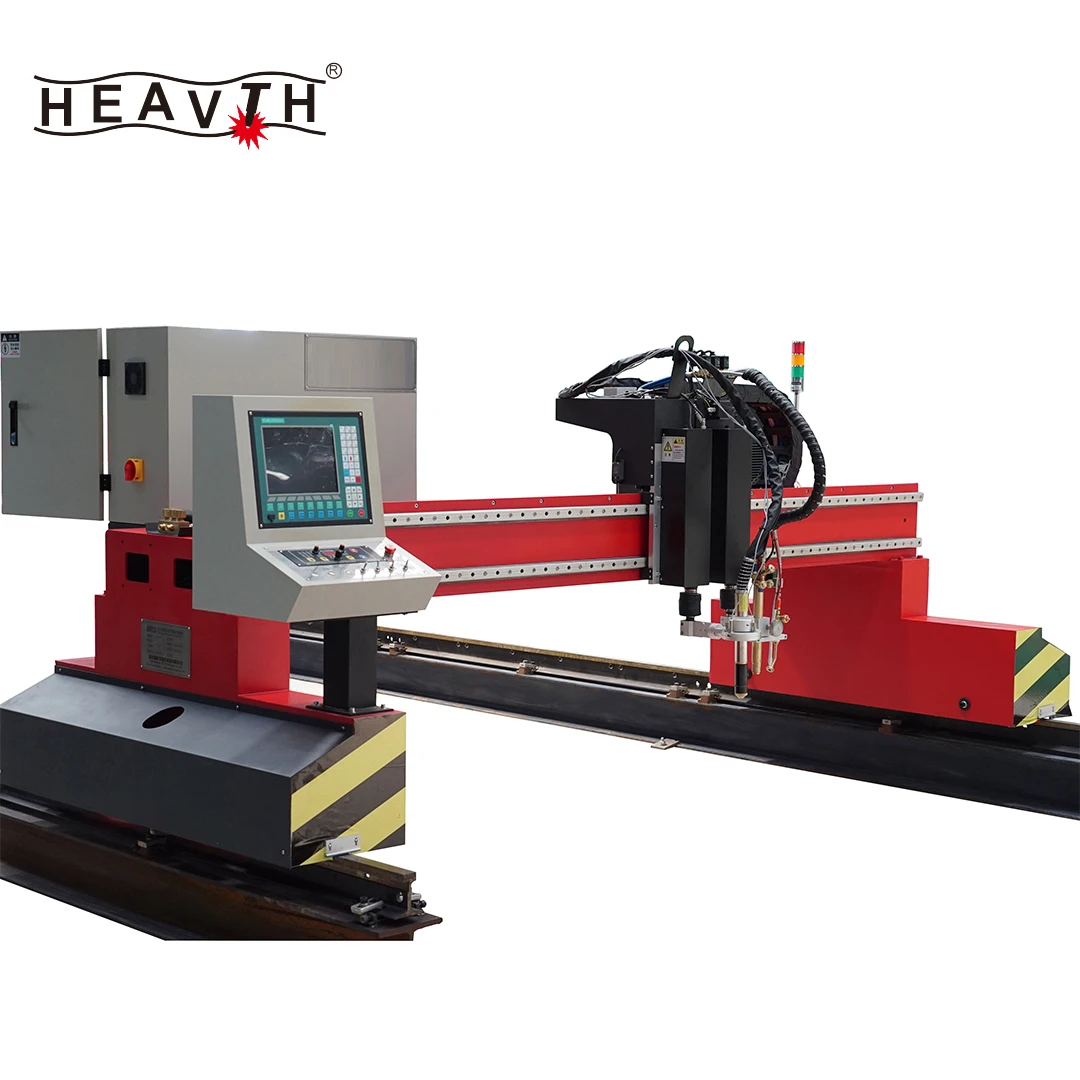

MS-3012HD Gantry Flame and Plasma CNC cutting machine

Gantry CNC cutting machine series of flame / plasma cutting machine is a high efficiency and high performance equipment, which uses gantry type, single drive or double drive. This machine uses advanced CNC system from abroad, such as Spanish FAGOR and American Hypertherm. Its excellent cutting parameters, reliable and stable features ensure the perfect cutting effect. CNC flame/plasma torch has auto height regulator and auto ignition functions, which is convenient for use.

Gantry Flame and Plasma CNC cutting machine is mainly used in all kinds of metal plates (such as: carbon

steel, stainless steel, aluminum, low alloy steel, aluminum alloy), but also in the complex pattern of the

above materials Processing.

Technical Specification | |

Product Name | MS-3012HD Gantry Flame and Plasma CNC cutting machine |

Model | MS-3012HD |

| Control system | Fang Ling F2300A |

Motor | Panasonic servo motor |

Color | Red,Blue,Yellow. |

Cutting Mode | Plasma Cutting+ Flame Cutting |

Flame Cutting Gas | Oxygen with propane or acetylene |

Plasma Torch Gas | Compressed air/N2/O2 |

Working Area | 2200mm*10500mm |

Cutting thickness | 0-150mm |

Cutting speed | 0-8000mm/min |

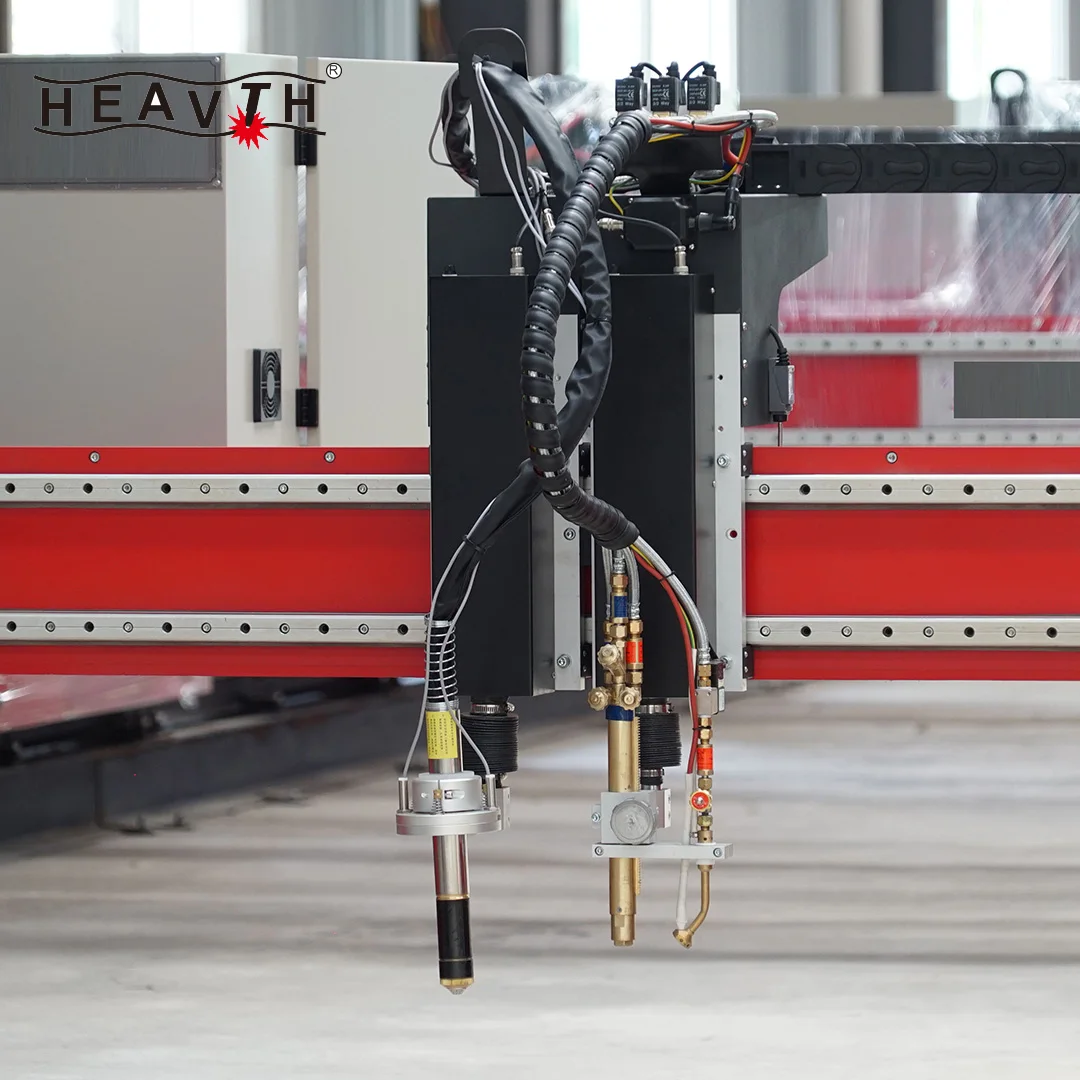

Operation precision | 0.2mm/m |

MS-4C series CNC plasma cutting machine is one of Messer's most mature models. It adheres to the high-quality and excellence manufacturing process that Messer CNC has always had.The machine runs smoothly and has rich configuration functions. High cost performance. The whole machine is made by laser cutting of the national standard 8mm steel plate, and the top and bottom are bent to improve the rigidity. The moving front plate is processed by a gantry planer, which greatly improves the rigidity of the whole machine and prolongs its service life. The structure of the whole machine is reasonably designed according to the golden section ratio. It uses the conventional central electrical control cabinet and central centralized gas path control design. The cable and gas pipe layout is reasonable, and the machine has good grounding and anti-electromagnetic interference performance. The requirements are configured with different numbers of plasma flame cutting heads to meet the requirements of different customers.

Main Features:

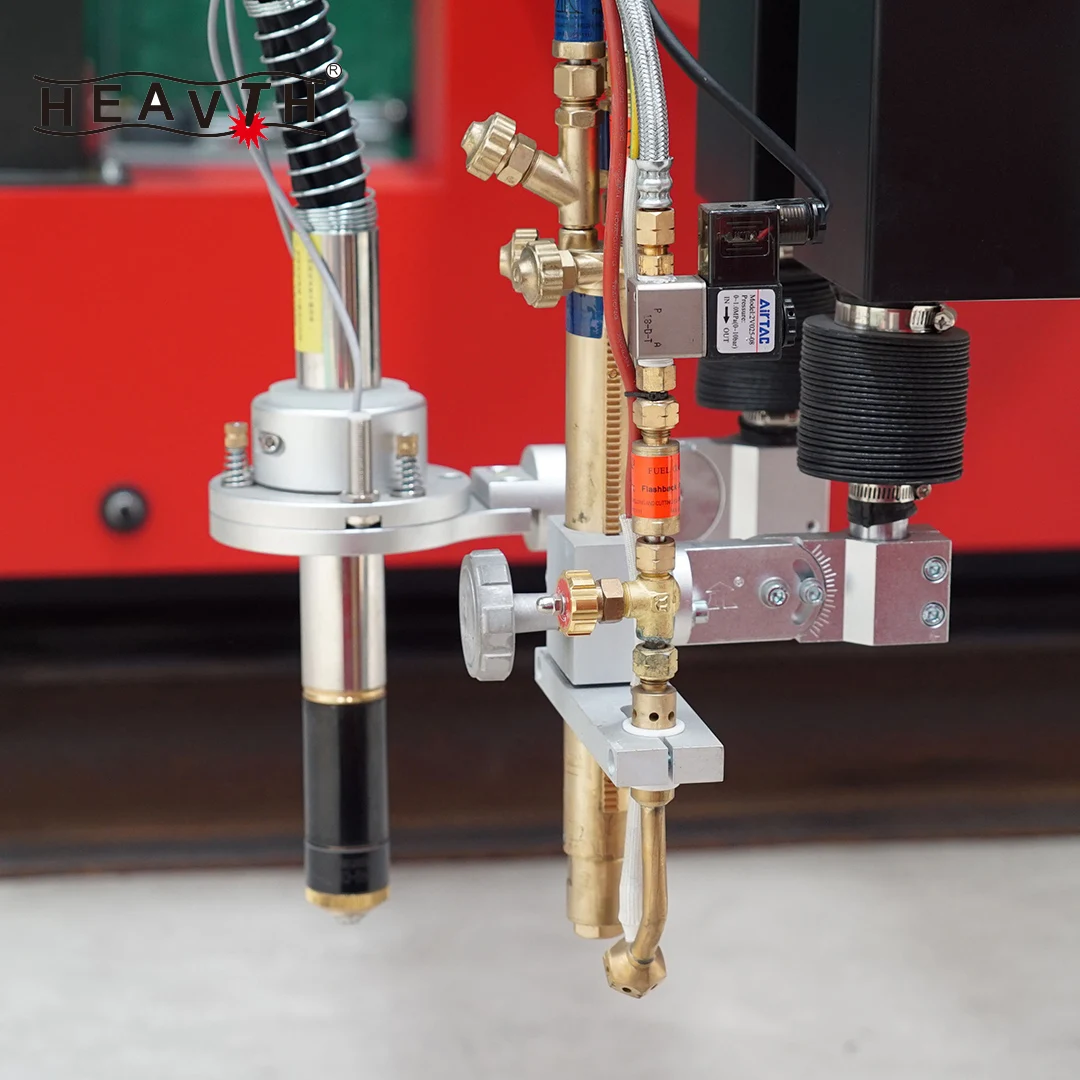

1.CNC gantry flame cutting is mainly suitable for cutting carbon steel within 5-200mm, and steel plates above 200mm require specific air valves; air pipes; and flame cutting torches

2.Flame cutting can realize automatic ignition device; it can greatly reduce the danger caused by industrial ignition and improve work efficiency;

3.Straight single cutting torch can perform high-precision cutting of 6-200mm carbon steel plates;

4.The straight flame cutting lifting device can manually adjust the cutting nozzle and steel plate scheduling manually;

5.Flame cutting gas source uses oxygen + gas (acetylene, industrial propane liquefied gas)

6.(Depending on the thickness of the steel plate; the size of the cutting nozzle used is different, see the flame and plasma reference table below for details)

QUALITY MANAGEMENT SYSTEM

Heavth CNC is one of the biggest suppliers among cutting equipment in east China. Company mainly engage in CNC Gantry cutting machine, CNC plasma cutting machine, CNC Pipe/Tube cutting machine, etc. Heavth CNC has 14 years history, serving more than 80 countries and regions.

Heavth CNC has strict quality control system and quality management team. Strictly adhere to the general standards of the industry and company guidelines. Implement quality monitoring from every aspect of R&D, production and after-sales of laser equipment, to ensure that each device can meet customer’s requirements.

Incoming Inspection

For every part of the machine, Heavth CNC is strictly control the quality.

Not only require suppliers to provide quality inspection reports, but also strict quality monitoring will be carried out when the parts are in the factory.

Plasma Source Test | Track and Rack Detection | Motor / Reducer Testing | |

| |||

Stability test and cutting test for plasma power source. | The precision and consistency between gear and rack are mainly tested | Load tester and oscilloscope are used to detect the consistency parameters and peak power of electronic components. | We will adjust the suitability of the machine through continuous empty experiments. |

Process Control

The assembly process of the machine will also affect the customer's feeling when using the machine, Therefore, in the process of machine assembly, Heavth CNC from the most basic machine bed to the final assembly of the whole machine is strictly followed by the quality management standard.

Machine Bed Welding | Gantry Milling | Guide Rack Mounting | Other Hardware Parts Installation |

| |||

The bed frame is welding by the China best steel plate | Heavth CNC has its own gantry milling, use planer processing to reduce secondary contact | The straightness of guide rack is guaranteed by using laser collimator | We install the motor reducer strictly according to standard production process |

Pre-delivery Inspection

The machine will accept a number of quality testing, respectively, from the performance, stability, fit, practical and other aspects of consideration, for non-compliance with the standard part of the arrangements for debugging and maintenance, To ensure that the final factory, the machine is in the best condition.

Inspection Report | Drawing Test | Cutting Test | Machine packing |

| |||

Every component of the machine, every performance, every parameter is carefully tested. | Ensure the cutting accuracy through drawing testing, and make sure the machine will be in the best condition. | Before delivery, different metal materials will be cut, observe the cutting effect, and then adjustment according to the need | The gantry equipment requires multiple protective measures during the packing process to ensure that each component is not affected by the collision |

Changzhou Heavth Science& Technogy CO.,LTD. was established in 2006.

We have many years of practical experience in motion control, software and hardware development, industrial automation, etc., .

Development and design of various types of CNC cutting machine and related accessories are widely used in the large number of industrial circle. Available to the user the best price, the most suitable CNC cutting machine. From the customer interests, according to the actual needs of customers, to provide the most economical and most effective CNC cutting solution.

Company research, production, operating as one, strong technical force, advanced production equipment, detection means complete, excellent product quality. Products covering the United States, Japan, Europe, South Korea, etc.