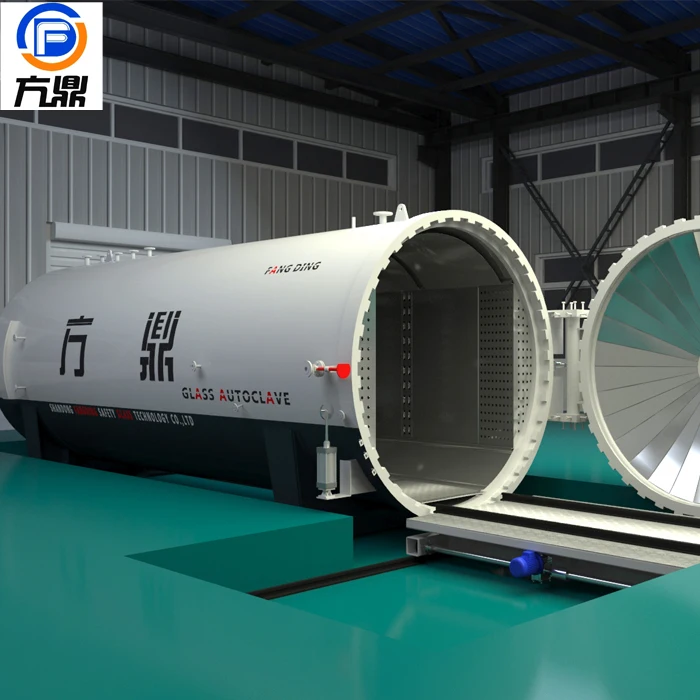

Автоклав для ламинирования стекла высокого давления Fangding

- Категория: Сосуды высокого давления >>>

- Поставщик: Fangding,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 85680.24 $* | 89964.46 $* |

| Aug-16-2025 | 84960.76 $* | 89208.12 $* |

| Jul-16-2025 | 71280.76 $* | 74844.50 $* |

| Jun-16-2025 | 83520.76 $* | 87696.29 $* |

| May-16-2025 | 72720.98 $* | 76356.56 $* |

| Apr-16-2025 | 82080.72 $* | 86184.73 $* |

| Mar-16-2025 | 81360.94 $* | 85428.28 $* |

| Feb-16-2025 | 80640.16 $* | 84672.32 $* |

| Jan-16-2025 | 79920.20 $* | 83916.38 $* |

Характеристики

High yield laminated glass autoclave for PVB film glass laminating

Technical parameters

Machine model: | ZCKJ-2500 |

Rated power | 370KW |

Processing glass size | Max:2500x6000mm |

Max glass thickness 60mm | |

Floor space | L*W:9000*4000mm |

Voltage | 220V-440V |

Net Weight | 20000kg |

Working temperature | 60degree--135degree |

Efficiency | 4 hours |

Max production capacity:400 Sq.m/cycle |

1.About us

Fangding Technology Co., Ltd. is a professional manufacturer of laminated glass machine and EVA film, the whole PVB laminating line for 17 years.

Our laminated glass machine have been sold to 68 countries and regions, most import to Europe.

Our equipment is self-development, and sales Top one in china. So we have rich experience in machine loading and delivery.

For PVB laminating line:

1.Our company has an independent research and development department, and acceptance team, from the source to carry out quality control for each detail, ingenuity quality, made in Fangding.

2.Provide a complete set of solutions for laminated glass technology, a technical team with 30 years of experience, on-site guidance installation training, and provide comprehensive after-sales service.

3.Our company has the qualification of pressure vessel production and is designed and developed in strict accordance with the GB150-2011 "pressure vessel" standard. The welding work employs a certified senior technician, which is strictly inspected according to the pressure vessel inspection standard before leaving the factory.

2.Workshop & Packing

We make strict Quality testing before packing by professional staff and engineer.

The machine packed with standard package, will be fixed firmly in the container.

It makes sure the machine arrived our customers’ factory with good condition.

3.Exibition

Fangding attend large exhibition both domestic and abroad every year!

We take both EVA laminated glass machine and autoclave to the exhibition, showing customers FangDing's advanced technology.

4.Certifications

Our company has the qualification of pressure vessel production and is designed and developed in strict accordance with the GB150-2011 "pressure vessel" standard. The welding work employs a certified senior technician, which is strictly inspected according to the pressure vessel inspection standard before leaving the factory.

1. Adopting new heating technology, the heating element is surrounded by four sides, strong wind convection cycle design, to achieve temperature balance in the autoclave, to ensure product quality, save energy and improve production efficiency.

1. Adopting new heating technology, the heating element is surrounded by four sides, strong wind convection cycle design, to achieve temperature balance in the autoclave, to ensure product quality, save energy and improve production efficiency.

2. Touch screen, PLC and other electrical appliances are equipped with international brands such as Siemens, South Korea LS, etc., with paper recording and data storage functions, real-time monitoring of temperature and pressure changes in the autoclave. Temperature and pressure with interlock control function, automatic temperature compensation, pressure compensation, to ensure pressure and temperature stability.

3. Unique cooling technology of high, middle and low grades can adjust the cooling speed according to the needs of customers or products to ensure the yield. As a main cooler, the fin heat exchanger has a large heat dissipation area and high heat exchange efficiency.

4. Device software can realize data exchange, output and storage. Call more than 40 sets of process parameters. With fault alarm and other functions.

5. Use 80mm environmentally friendly aluminum silicate insulation material, superior thermal insulation performance and reduce energy consumption.

6. All lines adopt the external wiring mode, which effectively prevents aging problems caused by excessive temperature in the furnace, prolongs the life of the line, and facilitates equipment maintenance and overhaul.

7. The company has the qualification of pressure vessel production, and the welding employs a senior technician with a certificate. Before leaving the factory, it is strictly inspected according to the pressure vessel inspection standard.

8. The company has an independent research and development department, acceptance team, from the source to the quality control of each detail, ingenuity quality.

9. With pressure detection device, multiple temperature detection, safe and reliable.

10. The vacuum line is reserved inside to facilitate the production of special process glass such as special shape and smart glass.

11. Provide a complete set of solutions for laminated glass technology, a technical team with 30 years of experience, on-site guidance installation training, and provide comprehensive after-sales service.9. With pressure detection device, multiple temperature detection, safe and reliable.

12. The vacuum line is reserved inside to facilitate the production of special process glass such as special shape and dimming.

13. Provide a complete set of solutions for laminated glass technology, a technical team with 30 years of experience, on-site guidance installation training, and provide comprehensive after-sales service.

FAQ:

Q: Could your machines laminate bent tempered laminated glass?

Re: Yes. Our machines can laminate large-size bent tempered laminated glass in one step, which is very easy to operate.

Q: How many stages your machines can set?

Re: Normally we set 5 stages from low to high temperature.

Q: When will your machine ready for delivery after our prepayment?

Re: It depends on your requirements.

Q: What about the terms of payment?

Re: Normally 30% prepayment, 60% before shipment by T/T, balance 10% should be paid after installation and sommissioning. L/C and other terms are also available.

Q: Does you machine have any certifications?

Re: Yes, we do. Especially for autoclave, we have "Manufacture License of Special Equipment", which is rarely owned by others suppliers. We can also apply for the certificate you need according to your requirements.

Q: How to operate the machine? Is it difficult?

Re: No, our machine is very easy to operate. The machine will work automatically after you set the parameters through the touch screen. We will send experienced senior engineers to teach you operating skills and production experience until you are proficient in operation.