Лидер продаж партиями по 4 рулоном гидравлическая листопрокатного машины с фокусным расстоянием 25

- Категория: >>>

- Поставщик: Jiangsu,Longsheng,Machine,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 51170.29 $* | 53729.78 $* |

| Aug-16-2025 | 50740.15 $* | 53277.79 $* |

| Jul-16-2025 | 42570.75 $* | 44699.17 $* |

| Jun-16-2025 | 49880.30 $* | 52374.33 $* |

| May-16-2025 | 43430.83 $* | 45602.84 $* |

| Apr-16-2025 | 49020.7 $* | 51471.75 $* |

| Mar-16-2025 | 48590.85 $* | 51020.3 $* |

| Feb-16-2025 | 48160.82 $* | 50568.59 $* |

| Jan-16-2025 | 47730.58 $* | 50117.80 $* |

Характеристики

Four roller plate rolling machine/rolling bending machine

* High performance

* High efficiency

* High quality with low price

* Easy control

* CE & ISO9001:2000 certification

* Can bend many material such as carbon steel, stainless steel, aluminum, alloy and etc.

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

Hydraulic Station

1. About the Valve, we use Yuken brand, it's from Japan. Its performance is very stable, and it's very durable.

2. The design of this hydraulic station is very energy efficient, can reduce power waste, and can reduce heat sources.

Control System & Display Screen

1. We use the self-developed four-roller rolling machine CNC system to achieve automated rolling.

2. Our display screen is SIEMENS, it's famous brand, normally, this display won't be going to be used badly.

3. About the display screen, you can choose a plastic cover to protect the screen. This is very necessary if used outdoors.

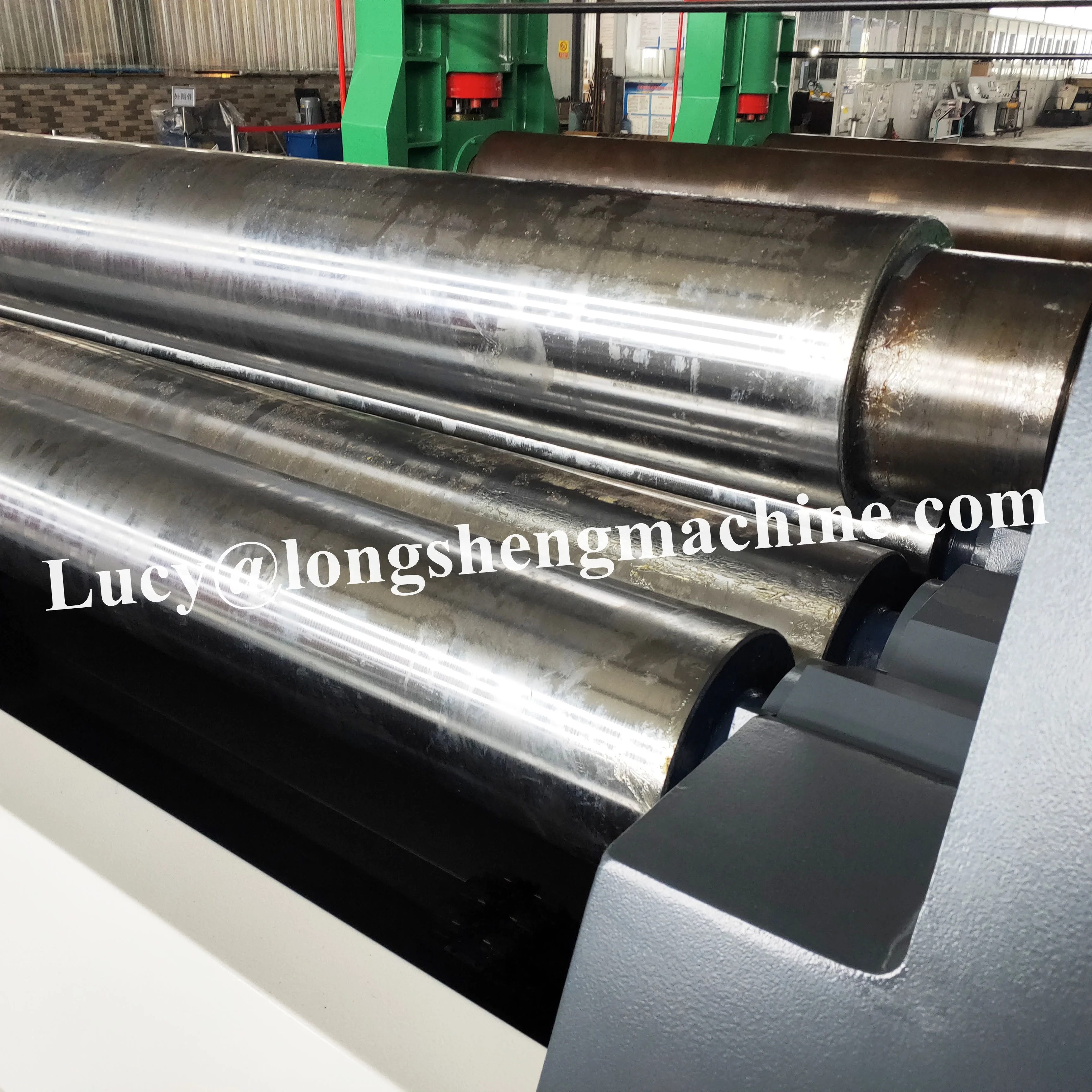

Rollers of rolling machine

1. The rollers are machined on a lathe and heat treated twice to ensure the strength and hardness of the rollers.

2. Finally, it needs to be polished by a cylindrical grinding machine to improve the parallelism of the roller shaft.

Motion detector

1. We use a rod-type displacement sensor(motion detector), which has the advantage of accurate positioning and no elastic deformation of the cable-type encoder.

2. This type motion detector cost is higher than normal cable-type encoder.

Protective cover

1. We use a protective cover to protect the hydraulic valve from iron filings, making it dirty and inconvenient to clean.

2. We arrange all the tubing wires in the wire trough to protect the tubing and wires from damage.

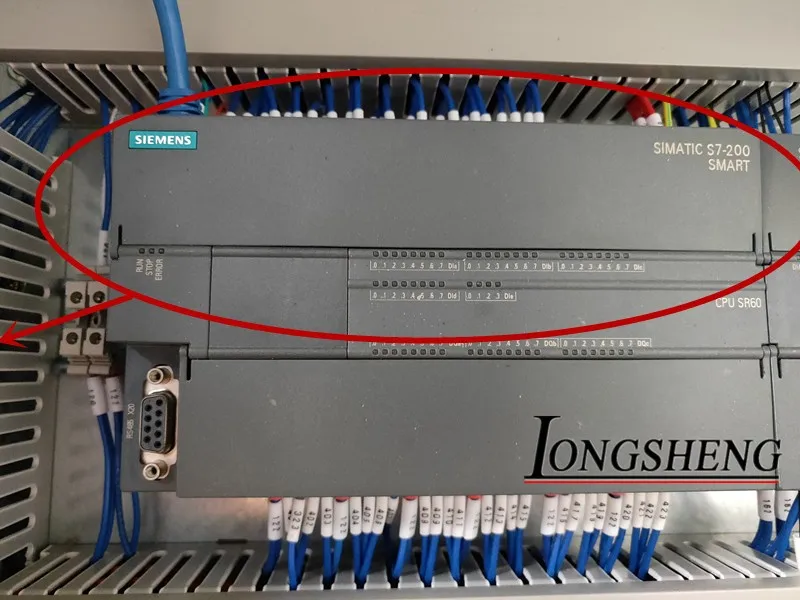

PLC

1. We use PLC from SIEMENS, it can be programmed, and can be real-time display of the position of each roller and the information of the rolling.

2. The SIEMENS PLC has a power-down memory function that is transmitted to the system in real time even after the position of the roller shaft changes after a power failure.

Electrical components

1. We use SIEMENS electrical components, it's safe, stable and not easy to break.

2. And in any country, you can buy this electrical component if it is really broken.

Hydraulic motor

1. This hydraulic motor is JST from China, it's famous brand in China.

2. It has a timely brake that can be stopped accurately to ensure the accuracy and effectiveness of the rolling.

Wear plate on both sides of the cylinder

1. We use wear-resistant copper plate, which has the advantage of being very wear-resistant but relatively costly. This is an optional accessory. If you need to use this wear-resistant copper plate, you need to tell me.

Jiangsu Longsheng Machine Tool Manufacturing Co.,Ltd is a competitive company, which is dedicated to development, production and sales of plate rolling machine/rolling bending machine and other sheet metal equipment with over 13 years. Adhering to the advanced European design concept, Longsheng follow the technology of Spain Sahinler and Italy Davi, combine with the actual needs of customers, and make well-structured and high-quality sheet metal fabrication equipment.Most importantly, it makes us be the professional sheet metal processing equipment supplier.

15 years experience

We are engaged in the manufacturing of rolling machine for 13 years. Exporting to many countries.

Quality guarantee

We use EU standards to ensure product quality.

24-hour service

24-hour online service to solve all problems of the products.

Custom packaging

We strive to create better service for our customers - to meet the requirements of customization.

Standard package

Our standard packaging is for protecting customers' rolling machine.

Loading and delivery

Helping arrange the shipping for customer.

Tel: +86-513-88281688

Mobile/Whatsapp/Viber/Wechat: +86-15951415788

Email: lucy@ longshengmachine.com

Http://www.longshengmachine.com