Описание и отзывы

Трекер стоимости

| Месяц |

Минимальная цена |

Макс. стоимость |

| Sep-16-2025 |

0.39 $* |

0.66 $* |

| Aug-16-2025 |

0.94 $* |

0.20 $* |

| Jul-16-2025 |

0.76 $* |

0.61 $* |

| Jun-16-2025 |

0.88 $* |

0.94 $* |

| May-16-2025 |

0.73 $* |

0.15 $* |

| Apr-16-2025 |

0.0 $* |

0.22 $* |

| Mar-16-2025 |

0.0 $* |

0.10 $* |

| Feb-16-2025 |

0.31 $* |

0.49 $* |

| Jan-16-2025 |

0.70 $* |

0.5 $* |

Характеристики

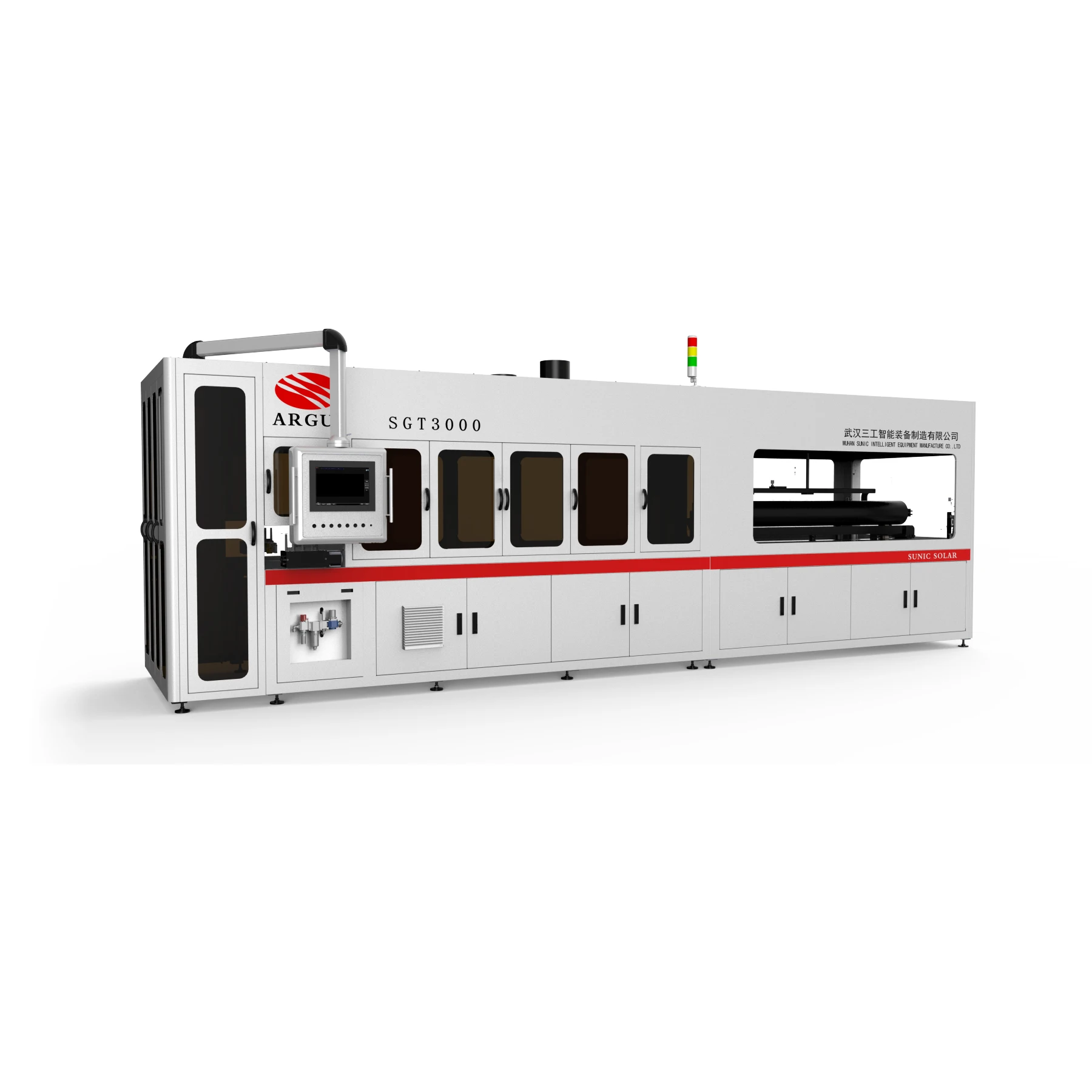

Argus Automatic Tabber Stringger solar cells soldering SGT1200 SGT3000 SGT4000

Equipment Performance

Tabber&Stringer adopts stress-free Hot-wind Wheel Soldering method, Servo motor Driving and Industrial CCD positioning&detection for defective solar cell excluding automatically. The soldering effect, such as Cell spacing, Cell numbers of single string, Soldering temperatures and etc, can be adjusted according to requirements. STS800 can be integrated with Automatic Layup machine to achieve the composing and locating of Solar cell Strings on Tempered glass.

Equipment Advance

1,Applicable for BIPV modules

2,Applicable for double side soldering

3,Proprietary soldering technology

4,Supportive for 5’’,6’’ and half cell size soldering

5,Exchange time less than 30mins from 3BB to 4BB, 5BB soldering head

6, Qualified soldering effect, which approves soldering pulling testing higher than 3N on cell surface(1.5mm ribbon, 180 degree pulling angle)

7,Exchange time less than 30mins for different sizes solar cells

8,Three Tabber&Stinger requires only one operator

9,Dual Solar string unloading basket to avoid working interruption

10,Ribbon extruding in advance before soldering

11,Pre-heating before soldering to avoid cell deformation efficiently

12,No manual operation works

13,Applicable for Solar cells thicker than 160um

14,Adjustable for Ribbon soldering spacing

15,Adjustable for Ribbon soldering length

16,Touchable integrated PC system is capable to resolve after-sales problem online

17,Can be integrated with other Solar equipment conveniently

18,Remote assistance by Internet

19,Adjustable for Solar cell spacing(1.5-35mm)

20,No pre-heating required for Ribbon before soldering

21,No specialized engineer required for maintenance

22,Solar cell soldering numbers per string can be set by PC

Equipment Hardware Specification

1.Machine body

The Solar cell district and Soldering district are totally enclosed on machine body. The solar string unloading basket can be integrated with Automatic Layup machine, or be transferred to string box.

The equipment adopts PLC control mode, with servo motor driving and multiply alarm system for safety guarding.

2.Rotary cell basket group

Servo motor driving+Liner Guide rail support+Double ball screw transmission

No friction during cell up&down process, to reduce cell breakage rate

Stratified Cell blowing structure to reduce cell breakage rate

Alarm notify when cell basket is empty

3.Cell Tilted Positioning CCD structure

Industrial CCD: 1 Mage Pixels

High resolution industrial camera lens

Servo motor driving+Liner Guide rail support+Double ball screw transmission

Flotation type positioning table

Automatically regulation when cell position is tilted.

Solar cell pre-heating

4.Soldering processing structure

High precision fiber sensor

Adjunctively Ribbon downwards structure

DC gear motor driving

Soldering flux immersing structure for Ribbon

5.Solar cell soldering structure

Hot-wind wheeling soldering method, and wheeling controlled by servo motor driving

Wheeling pressure adjustable

Soldering temperature adjustable

6.Unloading structure

Translation movement driven by servo motor

Lifting movement controlled by Guide Rod Cylinder

Solar cell rotary&overturn function

Dual Solar string basket structure

Alarm system for unloading vacuum control

7.Software control system

Specialized software for conveniently edit and modification

Friendly Human-machine interface for easy operation and control

Adjustable for edit and modification of soldering orbit according to requirement

Centralized Parameters can be set by keyboard through software window

Main parameters can be set and saved by software directly

Exchange between Automatic and Manual mode for convenient debugging

Soldering counting function

Error Alarm function

ABOUT US

Wuhan Sunic Photoelectricity Equipment Manufacture Co.,Ltd (Sunic Laser) have been engaged in manufacture of laser equipments since 1998. We are specialized in designing, manufacture, sales and service for laser processing machines and whole equipments for Solar PV production line, and supply complete turnkey solutions with laser application for customers all over the world.

![FBB.jpg]()