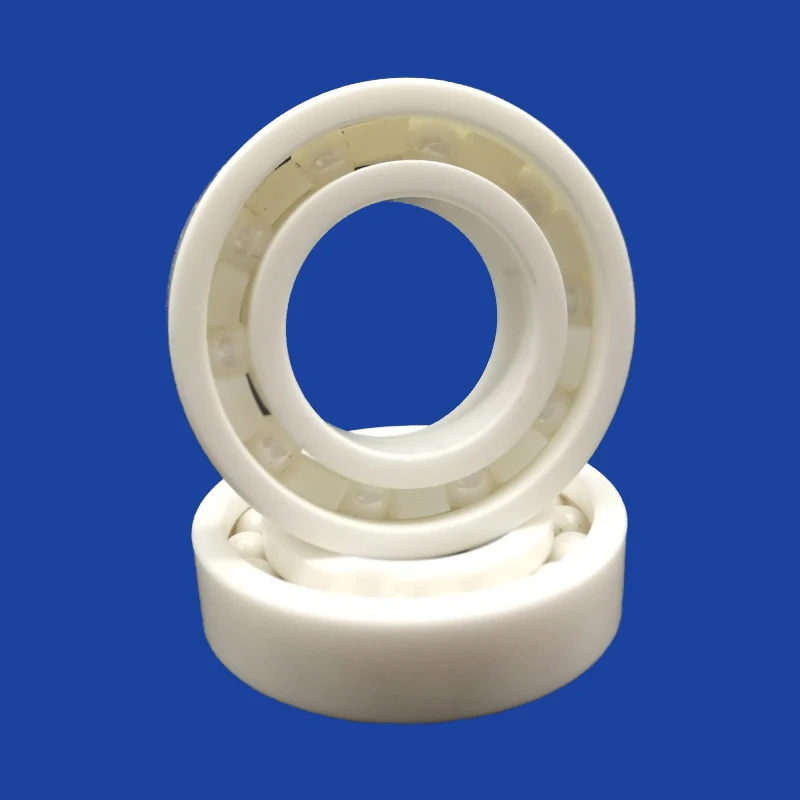

Высокопроизводительные керамические гибридные подшипники со стальными гонками и керамическими

- Категория: Керамические шарикоподшипники >>>

- Поставщик: Dongguan,Mingrui,Ceramic,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.16 $* | 0.98 $* |

| Aug-16-2025 | 0.99 $* | 0.51 $* |

| Jul-16-2025 | 0.86 $* | 0.98 $* |

| Jun-16-2025 | 0.98 $* | 0.2 $* |

| May-16-2025 | 0.1 $* | 0.4 $* |

| Apr-16-2025 | 0.74 $* | 0.99 $* |

| Mar-16-2025 | 0.88 $* | 0.5 $* |

| Feb-16-2025 | 0.89 $* | 0.84 $* |

| Jan-16-2025 | 0.35 $* | 0.86 $* |

Характеристики

High Perfomance Ceramic Hybrid Bearings with Steel Races and Ceramic Balls

Ceramic Hybrid Bearings have Steel races and Ceramic Balls. Ceramic Balls are suitable for applications where high loads, high speeds and extreme temperatures are factors. Long life and the need for minimal lubrication make this material appropriate for extreme applications. Ceramic is non-porous, non-magnetic, non corrosive and lighter than steel. In ball form, ceramic balls are also harder than steel and because ceramic balls are non-porous they are virtually frictionless and capable of spinning faster than steel balls.

Ceramic Balls are usually made of following materials:

Silicon Nitride (SiN4)

Alumina Oxide (Al2O3)

Zirconia Oxide (ZrO2)

Silicon Carbide (SiC)

Ceramic Hybrid Bearing Benefits

High loads, high speeds and extreme temperatures are factors

Increased bearing life and decreased down time

Minimal need for lubrication

No cold welding between ceramic balls and races

Multi-purpose use in variety of machines and different production lines

High efficiency, low weight and small size

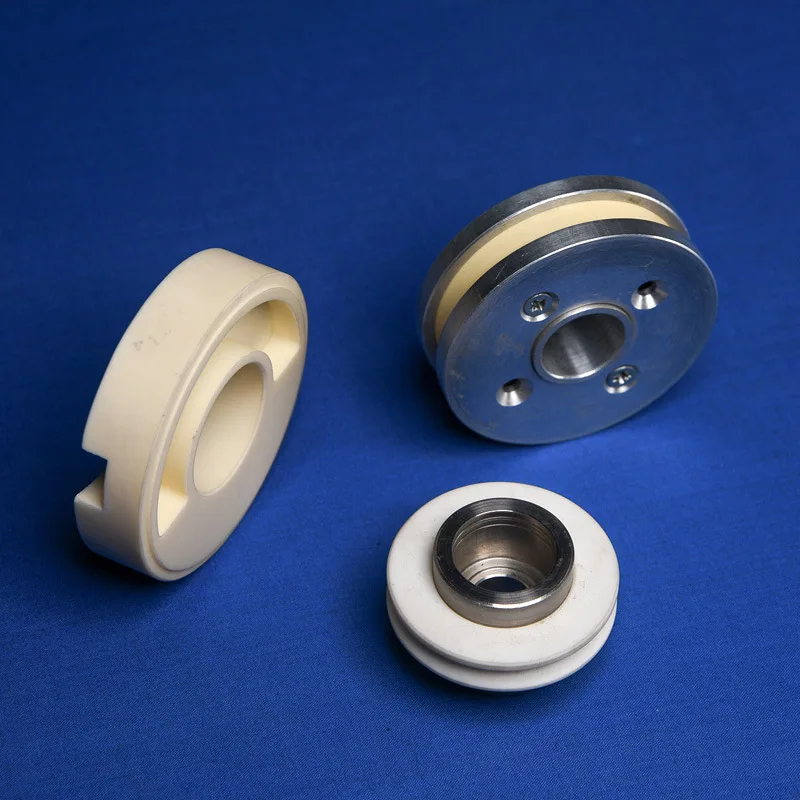

Ceramic Hybrid Bearing Applications

Ceramic hybrid bearings are widely used in electric motors, aerospace applications, performance racing vehicles, laboratory equipment, under water applications and more. Any application that requires higher speeds, lower friction and longer life are ideal for ceramic hybrid bearings.

| Precision | P0, P6, P5 or as requested |

| vibration | ZV1, ZV2, ZV3 or as requested |

| Clearance | C0, C2,C3 or as requested |

| Type | 60 series, 62 series, 63 series, 67 series, 68 series and 69 series |

| 511 series and all kinds of thrust bearing | |

| 70 series , 72 series and 79 series | |

| Feature | High temperature resistant,low density, strong solidity, low friction coefficient, abrasion resistance, magnetic resistance, Non-magnetic Insulating , acid and alkali resistance, good resistance to wear and tear, electric insulation, high speed,self-lubrication. |

| Quality standard | ISO9001:2000/ SGS |

| Quality Control Process | 1.Assembly |

| 2.Windage test | |

| 3.Cleaning | |

| 4.Rotary test | |

| 5.Greasing and gland | |

| 6.Noise inspection | |

| 7.Appearance inspection | |

| 8.Rust prevention | |

| 9.Product packaging | |

| Application | Ceramic bearings can be widely used in skateboard, aviation, spaceflight, navigation, petroleum, chemical industry, automobile, electronics, metallurgical, power, textile, pumps, medical equipment and scientific research. Electro plating, electro polishing ,Food processing, vacuum applications.fiber processing, conveyor processing. Medical radiation, photo processing,Computer assembly, electronics applications, Medicine equipment, wet applications. |

Ceramic material composition:

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

...

The properties of ceramic:

·Excellent physical & chemical stability ·High temperature resistance

·Excellent wear & pressure & corrosion& insulation resistance and thermal conductivity...

| Properties | Units | AL2O3 | ZrO2 | SiC | Si3N4 |

| Density | g/cm3 | 3.65-3.93 | 5.95-6.0 | 3.12 | 3.23 |

| Water absorption | 0 | 0 | 0 | 0 | 0 |

| Poission`s ratio | / | 0.21-0.22 | 0.3 | 0.17 | 0.26 |

| HV hardness hv | MPa | 1650 | 1300-1365 | 2800 | 1500 |

| Flexural strength | MPa | 310 | 950 | 390 | 720 |

| Heat conductivity | W/m*k | 26-30 | 2-2.2 | 120 | 25 |

| Electrical resistivity | Ω*mm2/m | >1016 | >1015 | >103 | >1013 |

| Dielectric constant | / | 9.6 | 29 | 9.66-10.03 | / |

| Dielectric strength | KV/mm | 8.7 | 9 | / | / |

| Coefficientof thermal expansion | 10-16/k | 7.9-8.5 | 10.5 | 3 | 3.2 |

| Modulus of elasticity young`s mod | GPa | 280-340 | 210 | 440 | 300 |

| Flexural strength(700℃) | MPa | 230 | 210 | 380 | 450 |

| Compressive strength | MPa | 2200 | 2000 | 1800 | 2300 |

| Max use temperature | ℃ | 1750 | 1050 | 1550 | 1050 |

| Resistance to acid alkaline | / | high | high | high | high |

| Thermal shock resistance | T(℃) | 180-220 | 280-350 | 230-260 | / |

| Fracture toughness | MPa*m1/2 | 4.2 | 10 | 3.9 | 6.2 |

| Tensile strength | MPa | 248 | 250 | / | / |

Manufacturing parameters:

| Additional Information:

| |||||||||||||||||||||||||||||

As a manufacturer of ceramic parts, we offer customization of ceramic for special sizes and shapes.High Precision, Fast Delivery Time, High Composition.

CULTURE

We are a leading manufacturer of industrial ceramic parts, who has years of R&D experience in China. And very advanced technologies in the production of zirconia and alumina ceramic tube, ceramic rod, ceramic plate, ceramic ring, ceramic sleeve, ceramic valve, ceramic piston plunger pump, and semiconductor ceramics, etc.

They are applicable to Electrical, Appliance, Mining, Oil & Gas, Energy & Power, Food & Medical, Agriculture, Aerospace, even other high-end fields.

Dongguan Mingrui Ceramic Tech. Co. Ltd.

Add: No.21 Chuangxing Rd., the 2nd Industrial Zone of

Shangsha,Chang'an town, Dongguan city, Guangdong,China

Tel: +86 0769 85090316

Fax: +86 0769 85090326

Skype: +86 18122972636

Mobile: +86 18122972636

Official website: http://www.cerampart.com/