Высококачественный полностью автоматический кромкооблицовочный клеевой станок для

- Категория: Wood Based Panels Machinery >>>

- Поставщик: Jinan,Goodcut,Cnc,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.60 $* | 0.58 $* |

| Aug-20-2025 | 0.84 $* | 0.32 $* |

| Jul-20-2025 | 0.99 $* | 0.65 $* |

| Jun-20-2025 | 0.9 $* | 0.68 $* |

| May-20-2025 | 0.9 $* | 0.27 $* |

| Apr-20-2025 | 0.72 $* | 0.31 $* |

| Mar-20-2025 | 0.41 $* | 0.63 $* |

| Feb-20-2025 | 0.3 $* | 0.87 $* |

| Jan-20-2025 | 0.30 $* | 0.79 $* |

Характеристики

Top quality full automatic edge banding glue machine for cabinet

Application:

The machine is suitable for such plates: MDF, block board, solid wood board, particleboard, polymer door plates, plywood etc, straight line edging and trimming. Function: pre-milling,gluing,edge cutting,end trimming, rough trimming, fine rimming, corner trimming, scraping, buffing, slotting and so on. Edging smoothly and edging line is straight. The machine is stable, reliable and durable, with favorable price. It is especially suitable for large and medium-sized furniture manufacturers.

1.Safety and thickness limitation ----Avoid wrong panel putting and hand pressing 2.Double rail fast end cutting ----Improve efficiency 3.Pneumatic pressing 4.Pre-milling ---- Milling the damaged part of the plate edge to achieve better edge sealing effect 5.Double glue pot ---- Save time and increase efficiency 6.Four heads corner trimming ---- Improve efficiency and effectiveness 7.Coding precise control --- Precisely control tape cutting and conveyor,saving edge tape

8.Pneumatic double trimming --- Better trimming and higher efficiency 9.Auxiliary feeding --- Optional for narrow plate safe feeding 10.Pneumatic scraping 11.Fracture wire and pneumatic polishing --- Pneumatic swing polishing better effect;Remove the shaved wire, avoid twining on the buffing wheels caused the motor stalled and burned out. 12.Automatic knife adjustment system --- No professional engineer required to adjust the machine |

Model | GC-EB |

Function | For edge banding machine, we have basis function: Gluing, End cutting, Fine trimming, Rough trimming, Scraping, Buffing. |

Electrical Lift | Yes |

Motor Power | 19kw |

Overall size(L*W*H) | 9200*1000*1900mm |

Feed Speed | 0-28m/min |

Panel Width | ≥60mm |

Panel Thickness | 10~60mm |

Edge Tape Width | 15~65mm |

Edge Tape Thickness | 0.4-3mm |

Advantage:

1.Adopt domestic famous motor and high quality electrical components.

2.The fuselage is firm and steady,thus increasing the stability of the whole machine.

3.Aluminum alloy beam is a relatively advanced method, its precision and straightness are far superior to cast iron.

4.Auto cleaning, high precision, high efficiency.

5.The machine can be customized.

6.Automatic and precise gluing procedure as well integrated double finishing side within one workflow .The end cutting can be done at the rear side of the machine.

7.Multiple Air cylinder will assembled on the machine, mainly used for positioned location assured the panel materials processing accuracy in a very high level.

8.Secondary Dust Exhaust System, mainly used for sawdust collection during processing period, to keep the material smooth and clean.

9.The machine adopts the devices of sound insulation, controlling of dust, platform frame Micro adjustment by manual operation.

1)The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

2)The buffing device adopt the board processed by cotton polishing wheel, by end- polishing to make a more smooth surface.

3)End-cutting mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the Cutting surface smoothly.

4) Scraping unit for a perfect finishing of the applied edge.

| 1 | Gluing, Fine trimming, Buffing. |

| 2 | Gluing, Fine trimming, Scraping, Buffing. |

| 3 | Gluing, Rough trimming, Fine trimming, Scraping, Buffing. |

| 4 | Gluing, End cutting, Fine trimming, Buffing. |

| 5 | Gluing, End cutting, Fine trimming, Scraping, Buffing. |

| 6 | Gluing, End cutting, Rough trimming, Fine trimming, Scraping, Buffing. |

| 7 | Gluing, End cutting, Rough trimming, Fine trimming, Scraping, Slotting, Buffing. |

| 8 | Gluing, End cutting, Rough trimming, Fine trimming, Scraping, Buffing. |

| 9 | Gluing, End cutting, Rough trimming, Fine trimming, Corner rounding, Scraping, Buffing. |

| 10 | Premilling, Gluing, End cutting, Rough trimming, Fine trimming, Corner rounding, Scraping, Bu |

Introduction for edge banding machine:

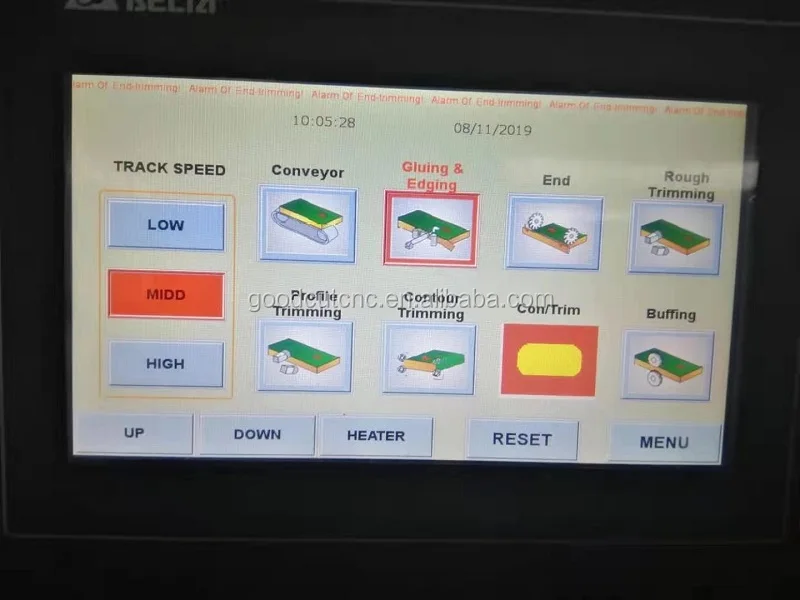

Jinan GoodCut automatic edge banding machine is equipped with Delta touch screen ,any errors of the machine are visiable in the touch screen control panel ,easier to repair and operate .Also the fine trimming sectionapplys high speed motor,ensure the high performance for trimming .Standard machine functions include gluing ,end cutting ,fine trimming ,flat scraping and buffing .All in one model that can meet your demands for various work for panel furniture edging . |

Features for GoodCut high quality China edge bander woodworking pre milling edge banding machine in Uzbekistan:

1 The glue mechanism adpot a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination. 2 The buffling device adopt the board processed by cotton polishing wheel, by end-polishing to make a more smooth surface. 3 Scraping unit for a perfect finishing of the applied edge. 4 Fine trimming unit using automatic tracking contour wheels and high speed motors ensure edges of panels smooth when trimming. 5 Rough trimming use flat knife which can prevent the thin veneer cracked.Besides rough trimming can be the first banding process of PVC and acrylic. This can reduce the cutting forces and wear of fine trimming cutter. |

Applications:

1.Cabinet,closet,panel furniture,office furniture,hospital furniture,bank furniture,children furniture.

2.It's mainly used for plywood,fiber board,partical board edge banding.

3.Various wooden door edge banding.

Edge Banding Effect:

High efficiency full automatic edge banding machine has additional functions such as corner trim and pre-milling etc., material edge banding work. This banding machine is widely used for kitchen cabinet, wardrobe, office table etc. furniture edging treatment, The edge banding material can be PVC, Acrylic, Veneer etc, It’s your idea selection for full functions automatic edge banding machine.

Smile Ji

Jinan GoodCut CNC Machinery Co.,Ltd.

Wechat/Whatsapp: 008618396857273

Email/Skype: smileji AT goodcutcnc.com