Однорычажный/двухрычажный смеситель песка для смолы

- Категория: Машины для литья металла >>>

- Поставщик: Qingdao,Hezhi,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 3451.45 $* | 3624.16 $* |

| Aug-16-2025 | 3422.44 $* | 3593.42 $* |

| Jul-16-2025 | 2871.23 $* | 3015.17 $* |

| Jun-16-2025 | 3364.10 $* | 3532.73 $* |

| May-16-2025 | 2929.39 $* | 3075.57 $* |

| Apr-16-2025 | 3306.68 $* | 3471.96 $* |

| Mar-16-2025 | 3277.48 $* | 3441.86 $* |

| Feb-16-2025 | 3248.49 $* | 3410.6 $* |

| Jan-16-2025 | 3219.37 $* | 3380.40 $* |

Характеристики

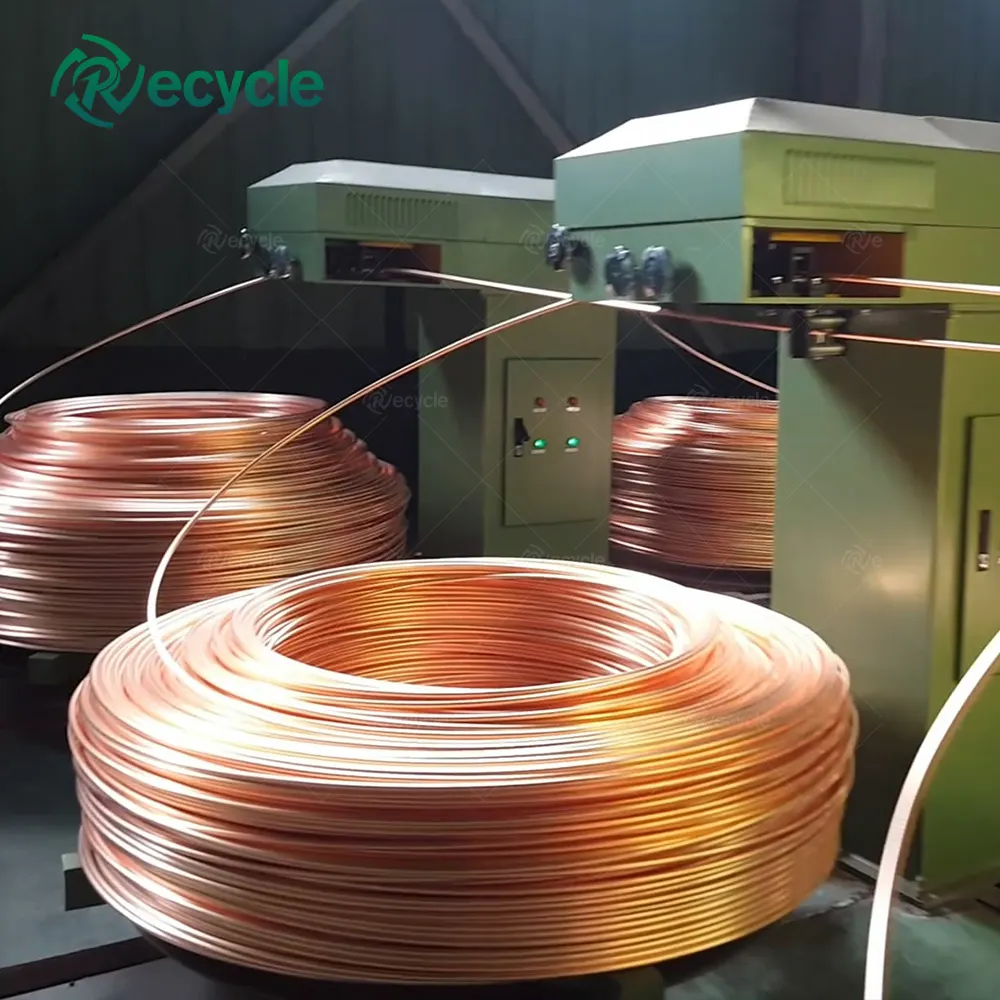

Resin sand mixer is a continuous operation of the resin sand mixing machine, Mixing outputs range from 3T per hour to 100T per hour, ideal for smaller foundries and catering for a number of individual customer requirements.

Resin sand mixer can be divided into: single arm resin sand mixer and double arms resin sand mixer .

Resin sand mixer can be divided into: single arm resin sand mixer and double arms resin sand mixer .

Resin sand mixer applies to single piece small batch manual molding ,also can be configured to core shooter and mould & core making production line.

Features of single arm resin sand mixer:Short mixing time,no head &tail sand, wide-open cage, easy to clean up the wal of sand , adjustable leaf, facilitate to operate and maintenance.

Model | S242 | S245 | S248 |

Productivity (t/h) | 2 | 5 | 8 |

Rotation rate (r/min) | 940 | 960 | 960 |

Motor power (kw) | 2.2 | 4 | 5.5 |

Gyration radius (mm) | R850 | R2000 | R2000 |

Curing agent for pump flow (l/h) | 49 | 49 | 75 |

Parameter | S255 | ||

Productivity | 5t/h | ||

Level 1 Sand Mixing Stirring Cage | Gyration Radius(m) | 2.5 | |

Gyration Range | 120° | ||

Motor Power (kw) | 2.2 | ||

Level 2 Sand Mixing Stirring Cage | Gyration Radius(m) | 1.35 | |

Gyration Range | 270° | ||

Motor Power (kw) | 4 | ||

We manufacture and design full scope of resin sand casting foundry equipment.

including Sand Mixer, Sand Feeder and Conveyor, Sand Moulding machine and Sand Reclamation Machines.

We also design custom Whole production line of resin sand casting produce.

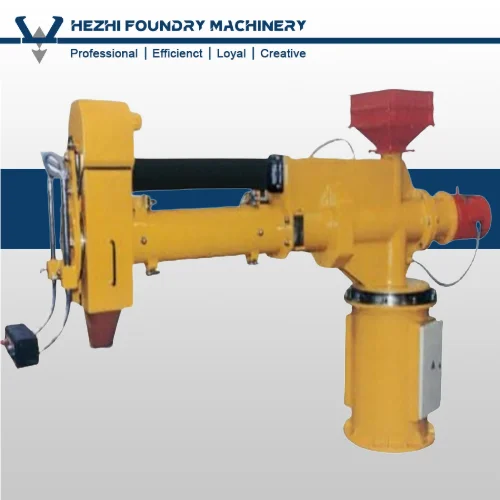

Finished Single arm resin sand mixer in Hezhi Workshop:

1. The split tube mixing trough and removable shaft ensure the system is easily maintained for greater longevity.

2. The pivotal mixer can be supplied with either the BASIC panel which excludes a PLC and has manually adjustable pumps. Or we can offer the PLUS panel which includes a PLC and all of the latest features automatic modes.

2. The pivotal mixer can be supplied with either the BASIC panel which excludes a PLC and has manually adjustable pumps. Or we can offer the PLUS panel which includes a PLC and all of the latest features automatic modes.

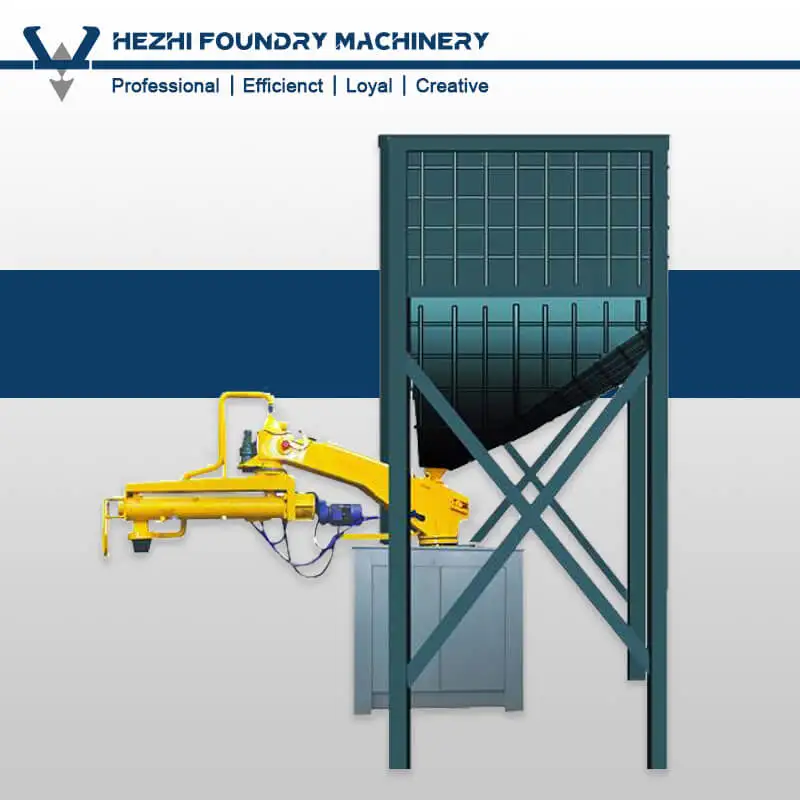

Finished Double arms resin sand mixer in Hezhi Workshop:

S25 series double-arm resin sand mixer is a new product designed and developed according to the operation requirements. The boom can be rotated by 180 degrees. If the arm is allowed, it can be rotated 360 degrees. The boom and arm are manually rotated. Both electric and electric remote control can be realized by electric, which enlarges the working area and makes the operation more flexible. It can meet the requirements of single-piece small batch manual modeling, and can also be arranged in the core shooting machine and mechanized modeling core production line. It can be used in a wide range of applications, mainly for the mixing of self hardening sand and water glass sand.

Resin sand mixer arm view:

Resin sand mixer control system and pump Parts:

Resin sand mixer pipes and valves :

Quality Control System In Hezhi Machinery Group:

1. The equipment raw materials (steel) and all accessories are strictly selected. Our suppliers are long-term cooperative and

reputable companies to ensure that the materials meet domestic and international standards.

2.Professional engineers with15 years rich experience provide professional & accurate detailed drawings and recommendations that meet customer all requirements, proficient in various technical parameters of the equipment,also will provide professional help

&solution for customers use and maintenance.

3. The workshop employees have many years of work experience in production and manufacturing, and the company also will regularly

train to ensure that production strictly follows all requirements of the process, drawings and contracts.

4. Workshop equipment is regularly maintained and optimized, and the company is still planning new workshops and introducing

moreadvanced new production equipment

5. The quality inspection department will conduct strict quality inspection on all raw materials, accessories and all products

produced to ensure the good quality of each equipment. Eliminate worries for customers

6. The client manager have many years of export experience, can better serve customers from various countries, and will also

participate in the inspection of equipment and work with the quality inspection department to ensure product quality.manager will

updating the production process to clients by sending pictures and videos every week.

7. Perfect after-sales service to solve customers' worries.

1. The equipment raw materials (steel) and all accessories are strictly selected. Our suppliers are long-term cooperative and

reputable companies to ensure that the materials meet domestic and international standards.

2.Professional engineers with15 years rich experience provide professional & accurate detailed drawings and recommendations that meet customer all requirements, proficient in various technical parameters of the equipment,also will provide professional help

&solution for customers use and maintenance.

3. The workshop employees have many years of work experience in production and manufacturing, and the company also will regularly

train to ensure that production strictly follows all requirements of the process, drawings and contracts.

4. Workshop equipment is regularly maintained and optimized, and the company is still planning new workshops and introducing

moreadvanced new production equipment

5. The quality inspection department will conduct strict quality inspection on all raw materials, accessories and all products

produced to ensure the good quality of each equipment. Eliminate worries for customers

6. The client manager have many years of export experience, can better serve customers from various countries, and will also

participate in the inspection of equipment and work with the quality inspection department to ensure product quality.manager will

updating the production process to clients by sending pictures and videos every week.

7. Perfect after-sales service to solve customers' worries.

Qingdao Hezhi is a manufacturer for Foundry Machinery & Shot Blasting Machine since 2005.

Products cover Moulding Equipment,Sand Reclamation Equipment, Sand Mixer, Dust Collector and full-line Shot Blasting Machines.

Products cover Moulding Equipment,Sand Reclamation Equipment, Sand Mixer, Dust Collector and full-line Shot Blasting Machines.

We owned 3600m2 work shop area for production with 2x10 cranes.

Another 2600m2 space is planned for extension.

ISO9001 is achieved. Full set of production ,QC(3 staff) and after-sales (3 staff) guarantee none-defective products.

3D Solidworks is used in designing. R&D staff with over 20 years expertise experience meet your customized requirements.

Our philosophy: Professional, Efficienct, Loyal,

Our mission: To creat core vlaue for our customer, our staff and our company.

Choose Hezhi,Get factory price and reliable Foundry Machinery!

Another 2600m2 space is planned for extension.

ISO9001 is achieved. Full set of production ,QC(3 staff) and after-sales (3 staff) guarantee none-defective products.

3D Solidworks is used in designing. R&D staff with over 20 years expertise experience meet your customized requirements.

Our philosophy: Professional, Efficienct, Loyal,

Our mission: To creat core vlaue for our customer, our staff and our company.

Choose Hezhi,Get factory price and reliable Foundry Machinery!

FAQ ---- About Resin Sand Mixer:

Q: Why is the amount of sand produced small?

A: 1. Check whether there is sand in the sand storage

2. Re-calibrate the sand outputof the sand mixer

3. The blade of the sand mixer is severely worn. Adjust the height of the worn blade or replace it with a newone.

4. The sand mixer's agitator cage has not been cleaned for a long time, resulting in agglomeration of the residual sand. When the

sand is mixed, the sand mixing space is small and the sand output is small.

Q:Why uneven curing?

A:1. Whether the ratio of resin and curing agent is uniform.

2. Check for leaks in the pipe joints of the hardener pump or resin pump.

3. Whether thepressure of the air supply source meets the requirements (0.4-0.6MPa).

4. The hardener pump, resin pump, and liquid valve need to be replaced.

5. Too much impurities in resin or hardener can cause blockage of pumps and pipelines.

6. Inspect the sand mixer blades for areas that need to be replaced.

7. As the temperature of the sand, the quality of the resin, the amount of the curing agent added, and the ambient temperature all

have a certain relationship, check whether the above conditions have changed.

FAQ ---- About Hezhi Machinery:

Q: Why is the amount of sand produced small?

A: 1. Check whether there is sand in the sand storage

2. Re-calibrate the sand outputof the sand mixer

3. The blade of the sand mixer is severely worn. Adjust the height of the worn blade or replace it with a newone.

4. The sand mixer's agitator cage has not been cleaned for a long time, resulting in agglomeration of the residual sand. When the

sand is mixed, the sand mixing space is small and the sand output is small.

Q:Why uneven curing?

A:1. Whether the ratio of resin and curing agent is uniform.

2. Check for leaks in the pipe joints of the hardener pump or resin pump.

3. Whether thepressure of the air supply source meets the requirements (0.4-0.6MPa).

4. The hardener pump, resin pump, and liquid valve need to be replaced.

5. Too much impurities in resin or hardener can cause blockage of pumps and pipelines.

6. Inspect the sand mixer blades for areas that need to be replaced.

7. As the temperature of the sand, the quality of the resin, the amount of the curing agent added, and the ambient temperature all

have a certain relationship, check whether the above conditions have changed.

FAQ ---- About Hezhi Machinery:

Q: How many days do you need to produce this machine?

A: It depends on the size of the machine. Usually20-30 days for shot blasting machine and sand machines, 45days around for production line equipments.

Q: What's your machine quality guarantee?

A: Usually it's one year. We will choose the world famous brand components to keep our machine in perfect working condition.

Q: Can you instal the machine overseas?How long will it take?

A: YES, we have rich-experienced install team to instal the machine for our customers worldwide.

More questions please contact with Anna, my phone No. is 0086 1995325 9235

Shot Blasting Machine

Похожие товары

Алюминиевые заготовки прокладок и по-прежнему для литья под давлением

US $18000-$200000

Литая машина для изготовления ювелирных изделий

US $339.71-$402.00