Высокомощные лазерные режущие станки IPG высокой мощности 12000 Вт лазерная резка для стальных станков из нержавеющей

- Категория: Industry Laser Equipment >>>

- Поставщик: Gweike,Tech,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.2 $* | 0.50 $* |

| Aug-19-2025 | 0.30 $* | 0.44 $* |

| Jul-19-2025 | 0.29 $* | 0.50 $* |

| Jun-19-2025 | 0.20 $* | 0.57 $* |

| May-19-2025 | 0.28 $* | 0.98 $* |

| Apr-19-2025 | 0.61 $* | 0.24 $* |

| Mar-19-2025 | 0.69 $* | 0.51 $* |

| Feb-19-2025 | 0.37 $* | 0.61 $* |

| Jan-19-2025 | 0.88 $* | 0.14 $* |

Характеристики

12000W High Power IPG High Power Fiber Laser Cutting Machines Laser Cutting For Steel Machines Stainless

Product Description

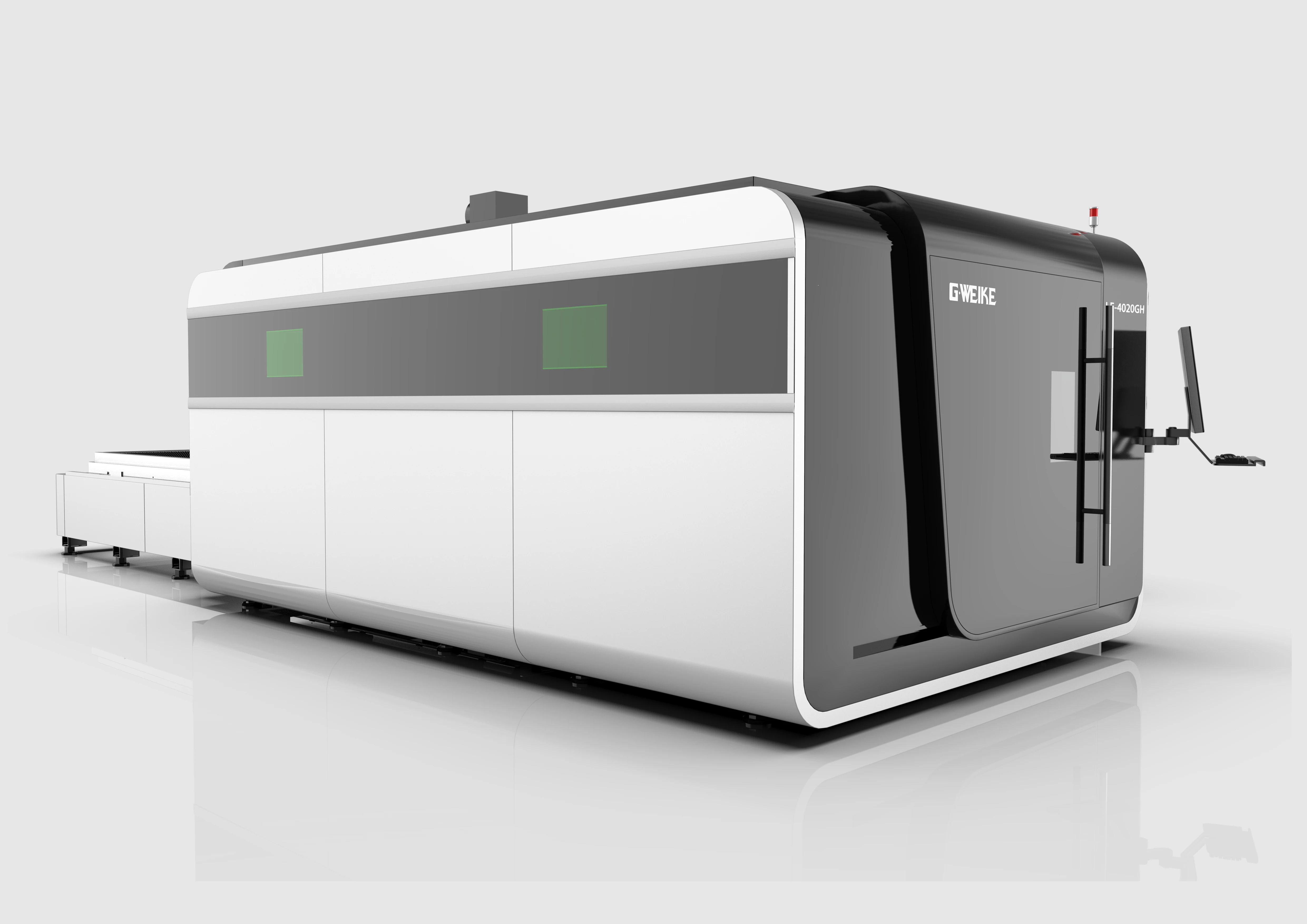

LF4020GA Fiber Laser Cutting Machine with a fully enclosed design;The observation window adopts an European CE Standard laser protective glass;

The smoke produced by cutting can be filtrated inside, it's non-polluting and environmentally friendly.

sample

Product features

1) Cutting with the possibility of physical marking.

2) Rapid response when controlling height. The control system is equipped with a capacitive contactless height controller, which provides quick response and accuracy, thus avoiding collisions between the laser head and the surface and achieving optimal focusing.

3) Jogging function in the cutting process, the function of reverse cutting, which allows to return to the uncut section in case of violation of process conditions, linear / circular interpolation and cut-off compensation function, automatic or manual combination.

4) Application of a number of technologies to increase the cutting speed.

5) Adjust the power of the laser to improve the quality of processing corners.

6) Edge search: the function allows you to place the laser head on the edge of the sheet, after which the system can automatically monitor the position and direction allowing the operator to adjust the position on the sheet.

7) The laser head allows cutting under gas pressure up to 3.0 MPa. High pressure gas lines enable the cutting of hard metals.

8) The machine has an automatic smoke exhaust system that ensures high cutting quality and no contamination of the environment.

9) Easy installation, operation and maintenance allows the machine to work 24 hours a day.

10) Machine body: the table is made by welding from sheet steel subjected to high-temperature annealing, processed on a foreign high-precision large-sized milling machine. The final product has a high mechanical strength and rigidity.

11) Under the working table, a system for collecting slag and small waste is installed.

12) The cooler provides high safety of work due to the presence of overflow protection, excessive pressure, incorrect connection of power supply, low voltage, overload, etc. The device is created on a completely imported element base and is characterized by stable operation and easy maintenance.

Technical Parameters

Product name | SALES! Short-time medium 4020 4000W CNC metal steel aluminum fiber laser cutting machine for UK | |

Quantity(set) | 1 | |

N.W(kg)/set | 8500 | |

G.W(kg)/set | 9000 | |

CBM(m3)/s et | 84 | |

Payment | T/T | 30% T/T deposit before production, 70% T/T balance before shipping |

Machine Modle | LF4020GA | |

Laser power | 500W 750W 1000W 2000W 3000W 4000W 6000W 8000W(Optional) | |

Delivery time | 45 working days | |

Working area | 4000mm x 2000mm

| |

Position accuracy, X, Y axis | ±0.03mm

| |

Repeat positioning accuracy | ±0.02mm

| |

Max. running Speed, X, Y axis | 120m/min

| |

Max. acceleration | 1.5G | |

Time of exchanging platforms | 15 - 17s | |

Max. Loding weight of sheet metal | 1100kg | |

Width of guide linear rail, X axis | 25mm | |

Width of guide linear rail, Y axis | 35mm | |

Voltage and frequency | 380V/50HZ/60HZ | |

Configuration of machine

SALES! Short-time medium 4020 4000W CNC metal steel aluminum fiber laser cutting machine for UK

1.Germany Precitec laser head, manual or automatic adjusting focal length (optional).

2.GERMANY IPG fiber laser generator.

3. Double exchanging platforms.

4. Protective cover from laser cutting working area.

5.Japan Yaskawa servo motor system.

6.Taiwan HIWIN guide linear rails.

7.Cypcut controlling system.

8.BEST Germany Atlanta double racks and pinions.

9.Germany Neugart reducer.

10. Pneumatic components, SMC from Japan/ Airtac from Taiwan.

11. Electrics components, Schneider from France.

12. Automatic lubrication system.

13. Smoke exhausting system.

14. Water cooling system.

15. Electronic cabinet with air conditioner.

using and maintainence cost

1. Electricity consumption: 29.1KW/hour.

2. Gas is needed to help cutting metals.

There are 3 choice of gas.

(1). Compressed air. Most cheapest choice.

(2). liquid nitrogen or nitrogen gas. it could keep color of original materials. Consumption of nitrogen gas: 80L/hour.

(3). Oxygen. It helps cutting fast.

3. List of quick-wear parts:

| Name | Life time | unit price |

| Protector mirror | 600 hours | $20 |

| Collimating lens | $250 | |

| Focus lens | $260 | |

| nozzle | 600hours | $13 |

| Ceramic ring | $50 |

Cutting parameter

| 2000W | 3000W | 4000W | 6000W | ||

| Material | Thickness | speed m/min | speed m/min | speed m/min | speed m/min |

| Carbon steel (Q235A) | 1 | 24--30 | 30--40 | 33--43 | 35--44 |

| 2 | 4.7--6.5 | 4.8--7.5 | 15--25 | 20--28.0 | |

| 3 | 3.0--4.8 | 3.3--5.0 | 7.0--12 | 13--17 | |

| 4 | 2.8--3.5 | 3.0--4.2 | 3.0--4.0 | 3.0--4.5 | |

| 5 | 2.2--3.0 | 2.6--3.5 | 2.7--3.6 | 3.0--4.2 | |

| 6 | 1.8--2.6 | 2.3--3.2 | 2.5--3.4 | 2.5--3.5 | |

| 8 | 1.2--1.8 | 1.8--2.6 | 2.0--3.0 | 2.2--3.2 | |

| 10 | 1.1--1.3 | 1.2--2.0 | 1.5--2.4 | 1.8--2.5 | |

| 12 | 0.9--1.2 | 1.0--1.6 | 1.2--1.8 | 1.2--2.0 | |

| 14 | 0.7--0.8 | 0.9--1.4 | 0.9--1.2 | 1.2--1.8 | |

| 16 | 0.6-0.7 | 0.7--1.0 | 0.8--1.0 | 0.8--1.3 | |

| 18 | 0.4--0.6 | 0.6--0.8 | 0.6--0.9 | 0.6--0.9 | |

| 20 | 0.5--0.8 | 0.5--0.8 | 0.5--0.8 | ||

| 22 | 0.4--0.8 | 0.4--0.8 | |||

| 25 | 0.3--0.55 | ||||

| 30 | 0.3--0.55 | ||||

| Stainless steel (201) | 1 | 24--30 | 30--35 | 32--45 | 42--52 |

| 2 | 9.0--15 | 13--21 | 16--28 | 20--33 | |

| 3 | 4.0--6.5 | 6.0--10 | 7.0--15 | 15--22 | |

| 4 | 3.0--4.5 | 4.0--6.0 | 5.0--8.0 | 10--15 | |

| 5 | 1.8-2.5 | 3.0--5.0 | 3.5--5.0 | 8.0--12 | |

| 6 | 1.2-2.0 | 2.0--4.0 | 2.5--4.5 | 4.8--8.0 | |

| 8 | 0.7-1.0 | 1.5--2.0 | 1.2--2.0 | 3.0--4.0 | |

| 10 | 0.6--0.8 | 0.8--1.2 | 1.6--2.5 | ||

| 12 | 0.4--0.6 | 0.5--0.8 | 0.8--1.5 | ||

| 14 | 0.4--0.6 | 0.6--0.8 | |||

| 20 | 0.3--0.5 | ||||

| 25 | 0.2--0.4 | ||||

| Aluminum | 1 | 15--25 | 25--38 | 35--45 | 42--55 |

| 2 | 7--10 | 10--18 | 13--24 | 20--40 | |

| 3 | 4.0--6.0 | 6.5--8.0 | 7.0--13 | 15--25 | |

| 4 | 2.0--3.0 | 3.5--5.0 | 4.0--5.5 | 9.5--12 | |

| 5 | 1.2--1.8 | 2.5--3.5 | 3.0--4.5 | 5.0--8.0 | |

| 6 | 0.7--1.0 | 1.5--2.5 | 2.0--3.5 | 3.8--5.0 | |

| 8 | 0.6--0.8 | 0.7--1.0 | 0.9--1.6 | 2.0--2.5 | |

| 10 | 0.4--0.7 | 0.6--1.2 | 1.0--1.5 | ||

| 12 | 0.3-0.45 | 0.4--0.6 | 0.8--1.0 | ||

| 16 | 0.3--0.4 | 0.5--0.8 | |||

| 20 | 0.5--0.7 | ||||

| 25 | 0.3--0.5 | ||||

| Brass | 1 | 10--16 | 20--35 | 25--35 | 35--45 |

| 2 | 4.5--7.5 | 6.0--10 | 8.0--12 | 20--30 | |

| 3 | 2.5--4.0 | 4.0--6.0 | 5.0--8.0 | 12--18 | |

| 4 | 1.5--2.0 | 3.0-5.0 | 3.2--5.5 | 5.0--8.0 | |

| 5 | 0.9--1.2 | 1.5--2.0 | 2.0--3.0 | 4.5--6.0 | |

| 6 | 0.4--0.7 | 1.0--1.8 | 1.4--2.0 | 3.0--4.5 | |

| 8 | 0.5--0.7 | 0.7--1.2 | 1.6--2.2 | ||

| 10 | 0.2--0.5 | 0.8--1.2 | |||

| 12 | 0.3--0.5 | ||||

| 14 | 0.3--0.4 | ||||

Related products

Jinan Gweike Science & Technology Co.,Ltd is professional manufacturer of fiber laser cutting machine, CO2 laser engraving cutting machine since 2004 year. All machines are approved with CE, ISO9001, certificates.

Our strengthen:

1. Self-owned research & development team.

First principle of our company -- QUALITY PRIORITY.

Our quality is well acknowledged on market.

So that our agents always keep stable relationship with us.

2. Reliable supplier with more than 350 stuff, 500m2 office and R&D space, 32,000m2 factory space, annual production ability is 3000 sets.

3. Price is lower and more competent than supplier of same glass.

4. 3-years warranty for whole machine.

On market most suppliers offer warranty 1 year or 2 years.

Contact us