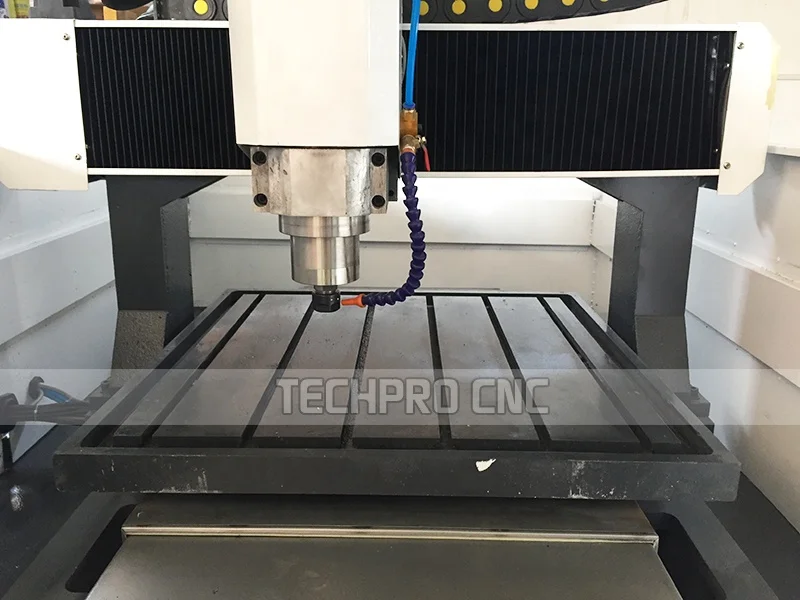

Китайский ЧПУ-роутер гравировальный станок для металла изготовление обуви ЧПУ-машина

- Категория: Оборудование для гравировки по металлу >>>

- Поставщик: Jinan,TechPro,CNC,Equipment,Co.,Ltd

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.88 $* | 0.52 $* |

| Aug-16-2025 | 0.76 $* | 0.65 $* |

| Jul-16-2025 | 0.3 $* | 0.40 $* |

| Jun-16-2025 | 0.64 $* | 0.45 $* |

| May-16-2025 | 0.20 $* | 0.32 $* |

| Apr-16-2025 | 0.0 $* | 0.46 $* |

| Mar-16-2025 | 0.8 $* | 0.89 $* |

| Feb-16-2025 | 0.94 $* | 0.97 $* |

| Jan-16-2025 | 0.38 $* | 0.69 $* |

Характеристики

Product Description

Application of Metal CNC Milling Machine:

The CNC milling machine is used for Iron, Copper, Aluminum, Stainless steel, mould steel, MDF sheets, PMMA, PVC Sheet, ABS sheet,KT sheet, Timber ,Gemstone, Marble, Aluminum and plastic composite panel, Iron, Copper, Aluminum, Plastics, etc.

1. It is suitable for engraving, milling and drilling compactly all sorts of materials such as steel, copper, aluminum and plastics.

2. It is widely used in automotive, injection mould, ironware mould and engrave mould industries.

3. It is especially designed for engraving and milling molds, eyeglasses, watch, panel, badge, brand, graphics and words of three-dimensional and outside surface's sleeking of large size molds.

Features Of Metal CNC Machine

1. Iron cast wholly frame, double-screw auto eliminating clearance ball screw, floor-type linear guide transmission.2. Breakpoint specific memory, power outages continued carving, processing time forecast, and other functions to ensure that accidental processing.

3. Vertical bracket, removable gantry, imported rack gear and ball screw transmission, Taiwan square linear orbit, can engrave 2mm-3mm little letter.

4. The CNC milling machine adopts advanced CNC system (NCstudio or DSP control system), has break point memory mode to make sure continuous working after electronic drop or other postpone situation.

5. Automatic oil lubrication system is easy to operate by one key press, equiped with dust proof and water proof for XY axis, make the maintenance operation easily.

6. Professional high flexibility anti-bending cable, the number of anti-bending can be up to 70,000 times.

7. Imported high-precision ball screw gap, smooth movement, to ensure that the machine tools high-precision.

8. Good three-axis and dust-proof structure to ensure that the machines longer service life.

9. Using well-known domestic brands of water-cooled brushless spindle, low noise, strong cutting ability, to ensure the long time working.

10. Designer perfectly, select the best machine accessories, to minimize the failure rate preferred.

11. High-performance driven motor to ensure that the machines high speed and accurancy.

12. The machine body is strong, rigid, high precision, reliable and durable. Whole steel structure, after high-temperature tempering, good rigidity and stability.

Machine samples

Detailed Images

Machine Configuration

Working Area: | 600*900mm |

Spindle Power: | China HQD 5.5kw constant water cooling spindle |

Spindle Rotating Speed: | 0-24000rpm |

Control System: | NC-Studio control system |

Power Supply: | AC380/220v±10, 50 HZ |

Worktable: | T-slot |

Driving Syestm: | Leadshine servo motors and drivers |

Transmission: | X,Y,Z: ball screw TBI and Hiwin square guide rail |

Locating precision: | <0.01mm |

Min Shaping Character: | Character:2x2mm,letter:1x1mm |

Operating Temperature: | 5°C-40°C |

Working Humidity: | 30%-75% |

Working Precision: | ±0.03mm |

System Resolution: | ±0.001mm |

Graphic Format Supported: | G code: *.u00, * mmg, * plt, *.nc |

Compatible Software: | ARTCAM, UCANCAM ,Type3 and other CAD or CAM softwares |

Packing&Shipping

Packaging detail:

1).Outside package: Standard marine export plywood case.

2). Inner package: Stretchy film and plastic film for humidity.

3). Machine packing size:1.25*1.55*1.8m ,GW: 300kg

2). Inner package: Stretchy film and plastic film for humidity.

3). Machine packing size:1.25*1.55*1.8m ,GW: 300kg

Shipping detail:

1) Machine has been adjusted and test 48 hours before delivery.

2) English software, User manual and detailed installation & training video in USB

3) Some extra spare parts (Pipe,limit switches etc)

2) English software, User manual and detailed installation & training video in USB

3) Some extra spare parts (Pipe,limit switches etc)

After Service

1.) Warranty: 3 years on parts from date of shipping date, Life-time technical support.

2.) Machine spare parts and repair service is offered in lifetime.

3.) Demand research, technical Seminar, application testing and samplings service.

4.) 30 domestic technicians, 10 oversea technicians, 5 online engineers, 24 hours technical online support by E-mail,Skype online contact software or door-to-door service.

Company Introduction

Jinan TechPro CNC Equipment Co., Ltd, Since 2007, it’s a high-tech enterprise producing CNC machine, focusing on the research and development and sales of industrial CNC products, Located in Jinan city (the hometown of CNC Machinery in China) ,has been steadily developing more than 10 years.We enjoy the advantage of strong international competitiveness and is a reliable partner for your long-term cooperation !