Абразивный шлифовальный

- Категория: Сварка и абразивы >>>

- Поставщик: Linyi,Hambo,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.26 $* | 0.25 $* |

| Aug-16-2025 | 0.73 $* | 0.18 $* |

| Jul-16-2025 | 0.16 $* | 0.7 $* |

| Jun-16-2025 | 0.60 $* | 0.52 $* |

| May-16-2025 | 0.78 $* | 0.60 $* |

| Apr-16-2025 | 0.22 $* | 0.58 $* |

| Mar-16-2025 | 0.75 $* | 0.88 $* |

| Feb-16-2025 | 0.69 $* | 0.73 $* |

| Jan-16-2025 | 0.29 $* | 0.22 $* |

Характеристики

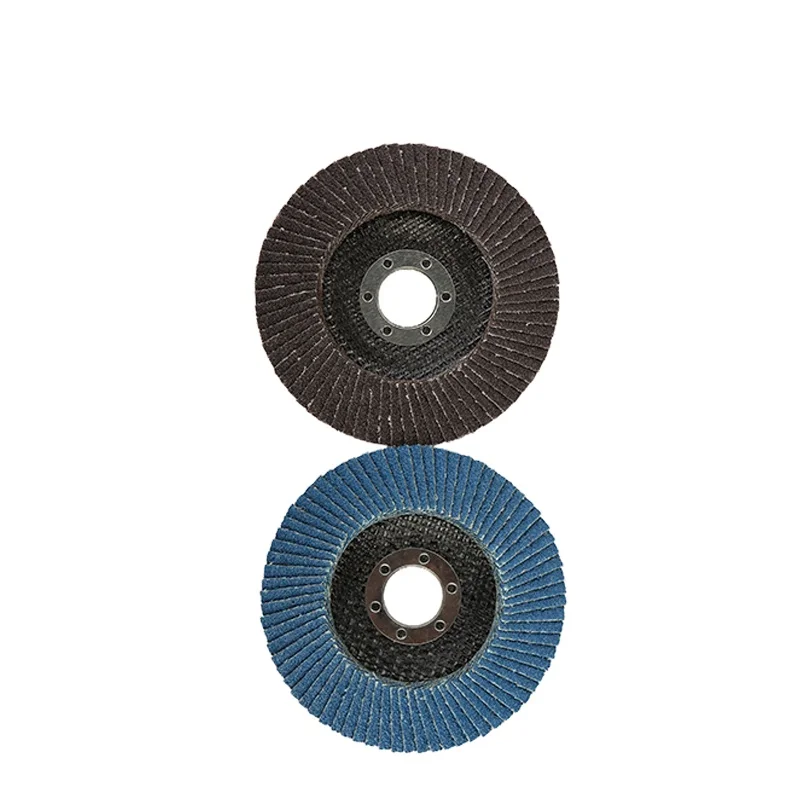

| FLAP DISC (CQL) | |||||||

| NO. | SPECIFICATION | MATERIAL | GRIT | M/S | PCS/CTN | G.W. | MEAS |

| 1 | 100X16-72 | ALUMINIUM OXIDE | 40#-120# | 80 | 200 | 13 | 55X23X23 |

| 2 | 115X22.23-72 | 80 | 200 | 15 | 47X25X24 | ||

| 3 | 125X22.23-72/80 | 80 | 200 | 17 | 51X26X24 | ||

| 4 | 150X22.23-100 | 80 | 200 | 26 | 61X31X28 | ||

| 5 | 180X22.23-120 | 80 | 100 | 21 | 38X38X30 | ||

| 6 | 100X16-72 | ZIRCONIA | 40#-120# | 80 | 200 | 13 | 55X23X23 |

| 7 | 115X22.23-72 | 80 | 200 | 15 | 47X25X24 | ||

| 8 | 125X22.23-72/80 | 80 | 200 | 17 | 51X26X24 | ||

| 9 | 150X22.23-100 | 80 | 200 | 26 | 61X31X28 | ||

| 10 | 180X22.23-120 | 80 | 100 | 21 | 38X38X30 | ||

Applications & Features It significantly improves life, grain retention and fray resistance.It's produced with raw material, stable and extremely high efficiency. | |||||||

-APPLICATION:

1.Bonded to extremely strong but durable fibreglass or plastic backing

2.Fast ,aggressive action for high pressure grinding, high efficiency

3.Blending and finishing all in one operation and will reduce process time, lower total grinding cost

4.Maximum contact with work surface with out loading

5.Consistent grinding and finishing performance

6.Excellent performance and efficiencies on stainless and carbon steel application.

-DIFFERENT TYPES:

Flap discs are used in heavy stock removal, often weld removal. They outperform Resin Fiber Discs due to their increased lifetime and last twice as long as Aluminum Oxide discs. To achieve a finish equivalent to a Resin Fiber Disc, always use a flap disc one grit coarser. e.g. If the operator is running a 60 grit Resin Fiber Disc, try a 40 grit flap disc. This 40 grit flap disc is made with Zirconia Alumina grain, which is ideal for stainless steel and metal applications while still working well with non-ferrous applications. The Type 29 angled face allows for 90% of the abrasive material to be in contact with work surface, yielding maximal grinding surface area for greater ease, effectiveness and speed. We use a high quality backing plate to help absorb vibration. Specific suited applications include: weld blending, removing weld slag, deburring, edge blending, surface conditioning and general metal fabrication.

-ADVANTAGES:

STRONGEST FIBER BACKING THAN OTHER PRODUCTS: 4 1/2 grinding wheels made for TOP-LEVEL Hard zirconia.Good material for griding wheel. This Flap Disc is constructed of industrial grade high density premium zirconia material, increased durability than standard flap discs, built for a more robust and economical grinding wheel.

LONGEST LASTING: Grinder sanding disc has long lasting time. Safe and Effective. Durable Material. Fast polishing,and it’s has durable fiberglass backing and fine crystal size.T29 flap disc construction with fiberglass backing plate effectively absorbs vibrations without smear during usage, bring more stable & efficient grinding.

We are Linyi Hambo Trade Co.,Ltd from China, a professional manufacturer of abrasives like flap wheels, cutting wheels and grinding wheels.

Question: How many years have been in this field ?

Answer: We are main deal with Abrasives, Cutting tools for more than ten years.

Question: Do you provide samples ? is it free or extra ?

Answer: Yes, free samples can be prepared for quality test , but costomers have to bare the cost of freight.

Question : How many days you need to prepare the samples?

Answer: We need 5-20 working days to prepare the samples

Question : Where is the loading port.

Answer: All ports in China, or as your requestment.

Question: How long is your delivery time?

Answer: Generally it is 15 days for our own brand DOME and 45 days after all details confirmed for OEM order.

Question: What is your terms of payment ?

Answer: T/T, L/C, Western Union, Money Gram, 30% T/T in advance ,balance before shippment.