Вакуумная пескоструйная машина без

- Категория: Sandblaster >>>

- Поставщик: Qingdao,Antai,Heavy,Industry,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 8330.46 $* | 8747.3 $* |

| Aug-17-2025 | 8260.46 $* | 8673.31 $* |

| Jul-17-2025 | 6930.19 $* | 7277.13 $* |

| Jun-17-2025 | 8120.28 $* | 8526.10 $* |

| May-17-2025 | 7070.48 $* | 7424.4 $* |

| Apr-17-2025 | 7980.85 $* | 8379.57 $* |

| Mar-17-2025 | 7910.82 $* | 8306.52 $* |

| Feb-17-2025 | 7840.97 $* | 8232.10 $* |

| Jan-17-2025 | 7770.27 $* | 8159.71 $* |

Характеристики

Product Description

Vacuum abrasive blasting machinefeatures an integrated blast pot, media vacuum recovery system, and dust collection all in a

single compact unit(consists of suction blast machine with remote control, blast hose, blast head assembly, reclaimer & separator

and pneumaticlly generated abrasive recovery system, dust collector and cart). it is widely used for descaling, surface texturing,

and paint preparation, mainly used to clean rust removing at oil field, container renew, etc, and pneumaticlly generated abrasive

recovery system makes it to be used without dust and disposal problem.

Blast and recovery systems can be used to simultaneously blast and recover (closed circuit blasting) or can be used for open air

blast and then subsequent abrasive clean-up.

Simultaneous blast and recovery eliminates dust clouds, poor visibility and costly clean-up. The capability of independent blast

and recovery makes the BRS a productive and versatile tool suitable to many different applications.

Vacuum Blasting is ideal for big objects such as ship hulls, large tanks and concrete bridge surfaces.

single compact unit(consists of suction blast machine with remote control, blast hose, blast head assembly, reclaimer & separator

and pneumaticlly generated abrasive recovery system, dust collector and cart). it is widely used for descaling, surface texturing,

and paint preparation, mainly used to clean rust removing at oil field, container renew, etc, and pneumaticlly generated abrasive

recovery system makes it to be used without dust and disposal problem.

Blast and recovery systems can be used to simultaneously blast and recover (closed circuit blasting) or can be used for open air

blast and then subsequent abrasive clean-up.

Simultaneous blast and recovery eliminates dust clouds, poor visibility and costly clean-up. The capability of independent blast

and recovery makes the BRS a productive and versatile tool suitable to many different applications.

Vacuum Blasting is ideal for big objects such as ship hulls, large tanks and concrete bridge surfaces.

No. | Iteam Parameter |

1. | Motor Power:7.5kw |

2. | Air volume:600m3/h |

3. | Volume:200L |

4. | Air pressure:0.5-0.6 MPa |

5. | Consumption Volume:6.1m3/min |

6. | Suction hose :15m |

7. | Dimension:1800L*800W*1700H |

8. | Weight:370 Kg |

9. | Clean speed:10-20m2/h |

Direction for use

使用说明

This equipment adopts compressed air power, high-speed abrasive blast to the workpiece surface, after removing the rust dirt of

the surface, the surface reaches a certain cleanness and roughness, through vacuum pump (or high pressure fan) to produce negative

pressure, recycle of sand and dust, through the equipment's sand and dust separation system will separate the complete abrasive

and rust dust, the abrasive will continue to recycle and the rust dust and dirt into the dust collecting barrel.

the surface, the surface reaches a certain cleanness and roughness, through vacuum pump (or high pressure fan) to produce negative

pressure, recycle of sand and dust, through the equipment's sand and dust separation system will separate the complete abrasive

and rust dust, the abrasive will continue to recycle and the rust dust and dirt into the dust collecting barrel.

Description of application effect

使用效果描述

Features :

1. Portable system used for lead and asbestos abatement, indoor blasting, bridge and road maintenance, building restoration and

other steel and concrete cleaning applications

2. Flexible system can blast and recover simultaneously or independently

3. Available in 2.0, 3.5 and 6.5 cu. ft. systems with pneumatic or electric remote controls

4. Cyclone has large, quick-opening access door and two-part screen with removable center for easy access

5. Optional, adjustable, air wash cyclone improves abrasive cleaning

6. Automatic pulse jet prevents clogging of dust filters

7. Quick opening hatches make cartridges and filters easy to remove and replace

8. Urethane eductor pump is available with 225, 350, 440, or 550 cfm nozzle

9. Moisture separator and media vibrator ensure even flow of abrasive

1. Portable system used for lead and asbestos abatement, indoor blasting, bridge and road maintenance, building restoration and

other steel and concrete cleaning applications

2. Flexible system can blast and recover simultaneously or independently

3. Available in 2.0, 3.5 and 6.5 cu. ft. systems with pneumatic or electric remote controls

4. Cyclone has large, quick-opening access door and two-part screen with removable center for easy access

5. Optional, adjustable, air wash cyclone improves abrasive cleaning

6. Automatic pulse jet prevents clogging of dust filters

7. Quick opening hatches make cartridges and filters easy to remove and replace

8. Urethane eductor pump is available with 225, 350, 440, or 550 cfm nozzle

9. Moisture separator and media vibrator ensure even flow of abrasive

Detailed Images

Size Information

1.8*1*1.8m

Related Products

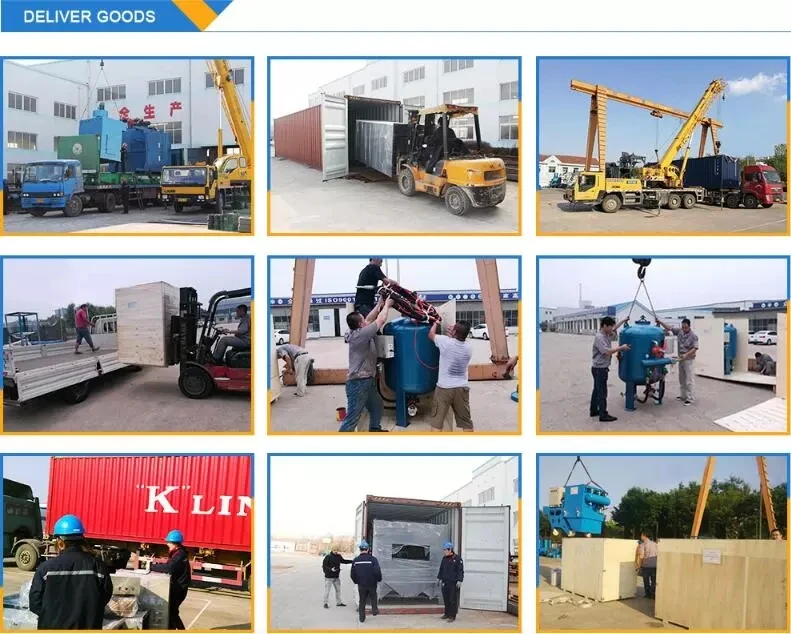

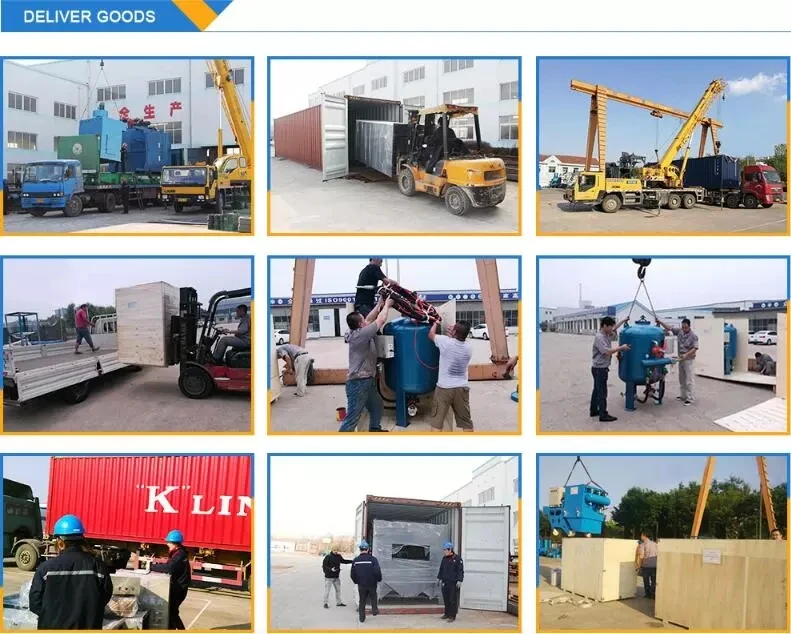

Packing&Shipping

1.Equipment painting completed before shipment, With Stretch film to avoid rub off the surface paint, It can used wooden cases

packaging according to users requirements.(Key parts such as electric cabinet with shockproof packaging material and then packed

in wooden cases. )

2. We have 15 experienced engineers, With 108 skilled workers insure good quality of our machines and prompt delivery.

3.Meanwhile our company has a long-term cooperation with ACL, CSCL, CCNI, CNC, COSCO etc insure the goods to the port on time.

packaging according to users requirements.(Key parts such as electric cabinet with shockproof packaging material and then packed

in wooden cases. )

2. We have 15 experienced engineers, With 108 skilled workers insure good quality of our machines and prompt delivery.

3.Meanwhile our company has a long-term cooperation with ACL, CSCL, CCNI, CNC, COSCO etc insure the goods to the port on time.

After Sales Service

What Service Antai can supply?

1. Our engineers can work separately according to the requirements of design for clients of the equipment. and send a customer

confirmation to help customers to save costs.

2. During the manufacture of the equipment, we photograph product production progress, and sent to the customer to track the

progress.

3. The goods hair go, we will send the original documents for the customer (such as packing list, bill, CO, Form E, Form A, Form

F, Form M, B/L etc.)

4. We can provide customers with free English foundation drawing, installation drawings, manuals, maintenance manuals and parts

drawings.

5. We can send our engineers to installation and debugging overseas, and free training of operators and maintenance workers.

6. We have a set of After-sales service system, A ID will be sent to each customer, they can log in this system that view all

information to buy equipment and parts by it. We provide 24-hour online consultation.

confirmation to help customers to save costs.

2. During the manufacture of the equipment, we photograph product production progress, and sent to the customer to track the

progress.

3. The goods hair go, we will send the original documents for the customer (such as packing list, bill, CO, Form E, Form A, Form

F, Form M, B/L etc.)

4. We can provide customers with free English foundation drawing, installation drawings, manuals, maintenance manuals and parts

drawings.

5. We can send our engineers to installation and debugging overseas, and free training of operators and maintenance workers.

6. We have a set of After-sales service system, A ID will be sent to each customer, they can log in this system that view all

information to buy equipment and parts by it. We provide 24-hour online consultation.

Company Introduction

FAQ

1. How many days do you need to produce this machine?

This is specially designed machine according to your specific requirement. From engineers designing to production completion, it

needs about 45-55 days.

2. What does your factory do regarding quality control?

We pay much attention to quality control from the very beginning to the end. Each machine is assembled and carefully tested before

shipment.

3. What's your machine quality guarantee?

Quality guarantee time is one year. We choose world famous brand components to keep our machine in perfect working condition.

4. Could you give installation and commissioning overseas? How long will it take?

Yes, we supply overseas service, but customers need to pay for the engineers flight tickets and hotel, food.

Small machines usually takes 5 days, while big machines usually takes about 20 days.

5. How can I trust you to deliver the right machine as I ordered?

We will absolutely deliver a good quality machine as we discussed and confirmed in the order. The core of our company culture is

innovation, quality, integrity and efficiency. Antai id ALIBABA's golden supplier with BV and Tuv assessment. You can check with

ALIBABA. We have never got complaint from our customers.

If the machine is not suitable for your workpiece, please tell us the following information:

1) What kind of workpiece will you clean?

2) The size of workpieces(length, width and height of maximum workpiece,Length, width and height of minimum workpiece?)

3) How many the weight of maximum and minimum workpiece?

4) Please tell us your requirement cleaning efficiency?

According to your infomation, the most suitable machines will be designed for your workpieces.

This is specially designed machine according to your specific requirement. From engineers designing to production completion, it

needs about 45-55 days.

2. What does your factory do regarding quality control?

We pay much attention to quality control from the very beginning to the end. Each machine is assembled and carefully tested before

shipment.

3. What's your machine quality guarantee?

Quality guarantee time is one year. We choose world famous brand components to keep our machine in perfect working condition.

4. Could you give installation and commissioning overseas? How long will it take?

Yes, we supply overseas service, but customers need to pay for the engineers flight tickets and hotel, food.

Small machines usually takes 5 days, while big machines usually takes about 20 days.

5. How can I trust you to deliver the right machine as I ordered?

We will absolutely deliver a good quality machine as we discussed and confirmed in the order. The core of our company culture is

innovation, quality, integrity and efficiency. Antai id ALIBABA's golden supplier with BV and Tuv assessment. You can check with

ALIBABA. We have never got complaint from our customers.

If the machine is not suitable for your workpiece, please tell us the following information:

1) What kind of workpiece will you clean?

2) The size of workpieces(length, width and height of maximum workpiece,Length, width and height of minimum workpiece?)

3) How many the weight of maximum and minimum workpiece?

4) Please tell us your requirement cleaning efficiency?

According to your infomation, the most suitable machines will be designed for your workpieces.

Похожие товары

Пескоструйная машина для удаления ржавчины и краски

US $1600-$6800

Industrial Sand Blaster filter cloth sandblasting

US $850.00-$1100

Small Automatic Sandblasting Machine Conveyor Type Sand Blaster

US $850.00-$1100