Пластиковая бетонная опалубка многоразового использования 50-60

- Категория: Formwork >>>

- Поставщик: Jinan,Alands,Plastic,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 26.10 $* | 27.27 $* |

| Aug-18-2025 | 26.60 $* | 27.37 $* |

| Jul-18-2025 | 22.94 $* | 23.70 $* |

| Jun-18-2025 | 26.43 $* | 27.88 $* |

| May-18-2025 | 22.51 $* | 23.69 $* |

| Apr-18-2025 | 25.67 $* | 26.10 $* |

| Mar-18-2025 | 25.74 $* | 26.64 $* |

| Feb-18-2025 | 25.36 $* | 26.32 $* |

| Jan-18-2025 | 24.14 $* | 25.77 $* |

Характеристики

Product description

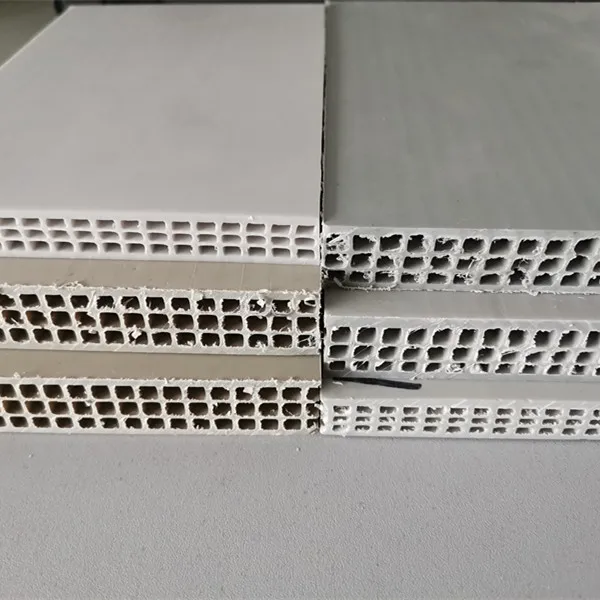

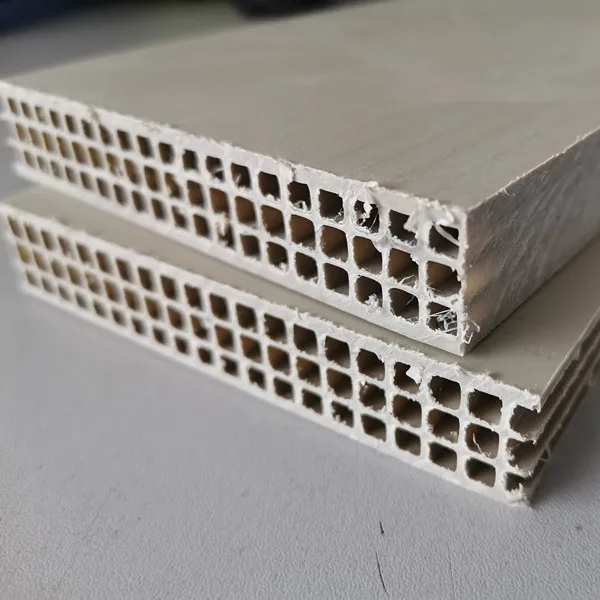

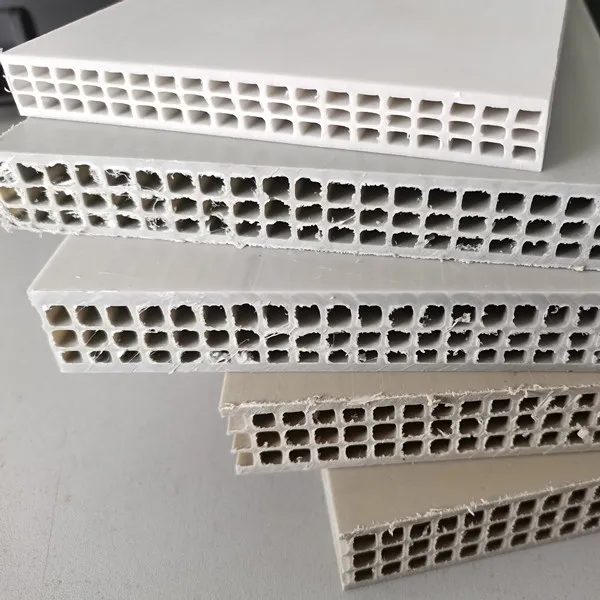

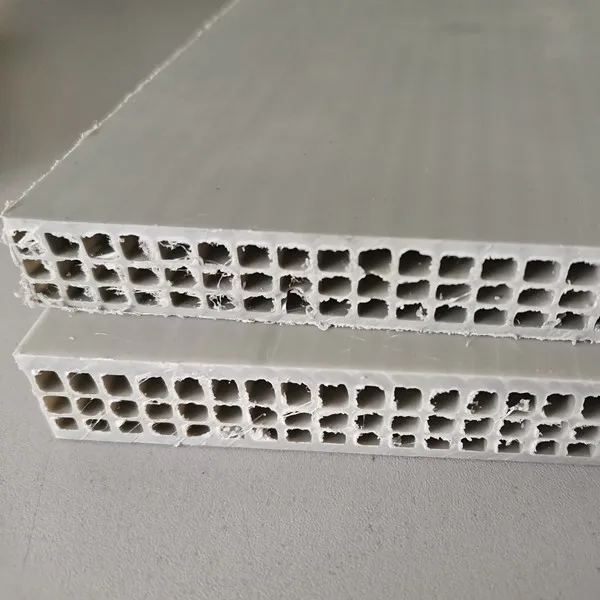

Our PP hollow construction formwork is an energy-saving and environmentally friendly product. It is another new generation product after wood template, combined steel template, bamboo-wood glued template, and all-steel template. Can completely replace the traditional steel formwork, wood formwork, square wood. It is energy saving and environmental protection, low amortization cost. Plastic building formwork can be used 50 times and can be recycled. Can be sawed, drilled, and easy to use. The flatness and smoothness of the surface of the formwork exceed the technical requirements of the existing clear concrete formwork. It has the functions of flame resistance, corrosion resistance, water resistance and chemical corrosion resistance, and has good mechanical properties and electrical insulation properties. It can meet the requirements of various cuboids, cubes, L-shaped, U-shaped building molds.

PP construction formwork | ||||||||

W X L (mm) | Thickness(mm) | Weight(kg) | ||||||

915 x 1830 | 11 | 10-11 | ||||||

915 x 1830 | 12 | 11-12 | ||||||

915 x 1830 | 15 | 13-14 | ||||||

915 x 1830 | 18 | 16-17 | ||||||

1220 x 2440 | 11 | 18-19 | ||||||

1220 x 2440 | 12 | 21-22 | ||||||

1220 x 2440 | 15 | 23-24 | ||||||

1220 x 2440 | 18 | 29-30 | ||||||

Application

Advantage

1. Flat and smooth surface.

8. Energy saving and environmental protection.

Formwork splicing is tight and smooth. After demolding, the concrete finish has smooth and clean surface, no need to plaster. Save labor and materials.

2. Light and easy to install.

Light weight, strong process adaptability, can be sawed, planed, drilled, nailed, can be composed of any geometric shape, to meet the needs of various shapes of building molds.

3. Easy demolding.

The concrete does not stick to the surface of the board, no mold release agent is needed, it is easy to demold, and it is easy to remove dust.

4. Stable weather resistance.

4. Stable weather resistance.

High mechanical strength, no shrinkage, no swelling, no cracking, no deformation, stable size, alkali resistance, anticorrosion, flame retardant and waterproof, rodent and insect resistance under the temperature of -10 ℃ to + 80 ℃

5. Easy to maintain.

5. Easy to maintain.

The template does not absorb water and does not require special maintenance or storage.

6. Strong variability.

6. Strong variability.

The type, shape, and specification can be customized according to the requirements of the construction project.

7. Low costs.

7. Low costs.

Can be used 50-60 times.

8. Energy saving and environmental protection.

All leftover materials and waste formwork can be recycled and reused, and zero waste is discharged, which saves a lot of timber resources for the country, and plays a huge role in protecting the environment, optimizing the environment and reducing carbon emissions. It also adapts to the direction of national industrial policy development, and is a new revolution in formwork materials for building construction projects.

Packing and shipping

Company Profile

1. The company has eight imported hollow plate production lines imported from Italy UNION and Wuhan Hyundai. With advanced production equipment, strong technical force, complete testing equipment and an annual production capacity of more than 10,000 tons. It has 120 employees and 29 senior and intermediate engineering technicians.

3. China's earlier and large-scale plastic hollow plate manufacturing and national import and export enterprises have advanced production equipment, strong technical force, complete testing equipment, and annual productivity can reach more than 10,000 tons.

4. Products are inspected, and products with quality problems can be replaced or remade at any time. Professional customer service team will make you more secure before and after sale. Alands Plastics will escort your products with actions.

2.The company's main plastic hollow board products are lightweight (hollow structure), non-toxic, non-polluting, water-repellent, shock-proof, anti-aging, corrosion-resistant, product color variety, exquisite printing on the board, and can be recycled .

3. China's earlier and large-scale plastic hollow plate manufacturing and national import and export enterprises have advanced production equipment, strong technical force, complete testing equipment, and annual productivity can reach more than 10,000 tons.

4. Products are inspected, and products with quality problems can be replaced or remade at any time. Professional customer service team will make you more secure before and after sale. Alands Plastics will escort your products with actions.