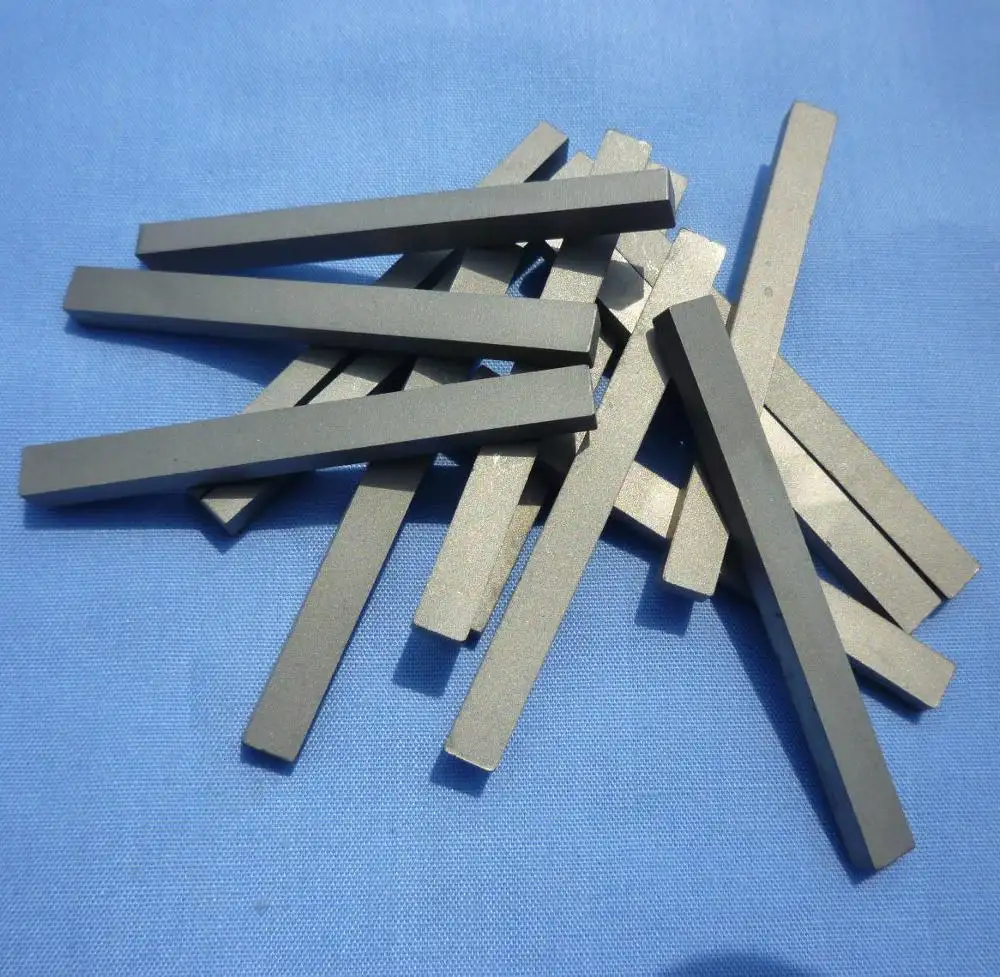

Наконечники из карбида вольфрама для резаков бамбука и

- Категория: Цементированный карбид >>>

- Поставщик: Zhuzhou,Xinpin,Cemented,Carbide,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.6 $* | 0.98 $* |

| Aug-16-2025 | 0.40 $* | 0.58 $* |

| Jul-16-2025 | 0.47 $* | 0.76 $* |

| Jun-16-2025 | 0.33 $* | 0.0 $* |

| May-16-2025 | 0.97 $* | 0.13 $* |

| Apr-16-2025 | 0.17 $* | 0.98 $* |

| Mar-16-2025 | 0.29 $* | 0.74 $* |

| Feb-16-2025 | 0.95 $* | 0.77 $* |

| Jan-16-2025 | 0.66 $* | 0.43 $* |

Характеристики

Competitive Advantage of TCT Carbide tips

More than 10 years manufacture experience in tungsten carbide

Implement strict quality testing and control procedure to make superior quality. (ISO9001)

Fexible payment terms(L/C, T/T, etc.)

Reply your inquiry within 8 hours

We are professional factory, so our price is lower than others

Professional sales person

Perfect Oral English communication service

Description of TCT Carbide tips for bamboo and wood stick cutters

1.Advantages

1. HIP sintering ensures good density and strength

2. Removing products surface stress and enhancing hardness by special process

3. various surface finishing ,to satisfy different welding ways for best welding and cutting performance

2.Grade and application

Tungsten carbide tips for wood,steel,iron,and aluminum products introduction:

1.Tungsten carbide ( Cemented Carbide) tips (bit) Application:

Wood use tips: ordinary wood, hard wood, recycled wood,

Soft metal: aluminum and copper, lead and other non-ferrous metals, soft metals,

Panel : industrial plywood, MDF and sandwich panels, and other professional cutting,

Steel : professional cutting for steel, metal and other .

2. Carbide tips insert surface quality requirements:

Carbide tips surface must not be stratified, crack and bubbling, obvious decarburization and other defects. as for the cutting edge of saw balde, the maximum size of off-angle shall not exceed 0.15mm, off-angle not on the cutting adge shall not be greater than 0.3mm.

3. Carbide tips surface color requirements:

After surface treatment, saw blade uniform color, no debris, no oil and so on. After passivation the surface color is gray-black, after sandblasted the surface color is silver-gray, after coating is become silver-white.

4. Tungsten carbide tips welding recommendations: Can use resistance welding, the temperature should not be too high.

5.EJ Carbide tips package and transportation:

tips per 1Kg with plastic bottle, placed in a dry cardboard box, with paper or cotton Cypriot, the carton placed in wooden box, or plastic box. Each carton box weight shall not exceed 30Kg. Products should be transported to prevent moisture, not a violent collision. The product should be stored in a dry, acid and alkali atmosphere, to prevent corrosion.

Grade Chart

| Grade | Density(g/Cm³) | Hardness(HRA) | T.R.S(N/mm2) | Recommended Cutting Application |

| SM02 | 15.0-15.2 | 94.5-94.8 | ≥2200 | For chipboard,MDF&HDF,Jaminated board,etc. |

| SM03 | 15.0-15.2 | 94.0-94.4 | ≥2500 | For veneer board,MDF&HDF,aluminum extrusions,etc. |

| SM06 | 14.9-15.1 | 93.6-94.0 | ≥2600 | For hardwood,copper,aluminum,plywood,MDF and Acrylic,etc. |

| SM07 | 14.8-15.0 | 93.2-93.6 | ≥2700 | For solidwood,hardwood,cooper,aluminum,plywood,etc. |

| SM09 | 14.6-14.8 | 92.4-92.8 | ≥2800 | For ceramic tile,solidwood,hardwood and various woodworking tools,etc. |

| SM10 | 14.2-14.4 | 92.0-92.5 | ≥3000 | For hardwood,Non-ferrousMetal,PCB circuit board and various woodworking tools,etc. |

| SM12 | 14.2-14.4 | 91.8-92.3 | ≥3000 | For stainless and alloy steel,etc. |

| XF5 | 14.9-15.1 | 91.2-92.0 | ≥2100 | For solidwood,composite board and Non-Ferrous Metal,etc. |

| XF6 | 14.7-14.9 | 92.0-92.8 | ≥2200 | For solidwood,hardwood and composite board,etc. |

| XF8 | 14.5-14.7 | 91.0-92.0 | ≥2300 | For construction formwork,Non-ferrous Metal and various woodworking tools,etc. |

| XF10 | 14.3-14.5 | 90.5-91.5 | ≥2400 | For wolidwood,hadwood and various woodworking tools,etc. |

| XK10 | 14.8-15.0 | 90.5-91.5 | ≥2200 | For solidwood,hardwood,etc. |

| XK20 | 14.6-14.8 | 89.5-90.5 | ≥2400 | For softwood,solidwod,etc. |

| XP40 | 13.0-13.2 | 91.2-91.8 | ≥2800 | For alloy steel,stainless steel and high-manganese steel,etc. |

| XP30 | 13.1-13.3 | 91.4-92.0 | ≥2700 | For common steel,color steel tile,etc. |

| YG8C | 14.6-14.8 | 88.0-89.0 | ≥2700 | For weed,shrub,medium hard rock formation and natural stones,etc. |

| YG11C | 14.3-14.5 | 87.0-88.0 | ≥2600 | For marble,granite and various mining tools,etc. |

| YG15C | 13.9-14.1 | 85.5-86.5 | ≥2800 | For oil drill,stamping die material,etc. |

| YG20C | 13.4-13.6 | 83.0-84.0 | ≥3000 | For various stamping die material,etc. |

Note:HIP(hot isostatic pressing)can effectively eliminate the internal porosity of the alloy and significantly improve the bending strength of the product.

Date reported in the fable are standard typical values which maybe changed with our company's notice.

Dimension: Please see the below sizes, customized base on customer drawing or samples

| Type | L | T | L1 | α° | β° | γ° | R1 | W |

| JX3018602010-1.8 | 3.0 | 1.8 | 1.0 | 60 | 20 | 0 | 0.5 | 1.8 |

| JX4020652010-2.0 | 4.0 | 2.0 | 1.0 | 65 | 20 | 0 | 0.5 | 2.0 |

| JX5518602020-2.2 | 5.5 | 1.8 | 2.0 | 60 | 20 | 0 | 0.5 | 2.2 |

| JX6020602020-2.4 | 6.0 | 2.0 | 2.0 | 60 | 20 | 0 | 0.5 | 2.4 |

| JX7020602025-2.8 | 7.0 | 2.0 | 2.5 | 60 | 20 | 0 | 0.5 | 2.8 |

| JX8025602030-3.0 | 8.0 | 2.5 | 3.0 | 60 | 20 | 0 | 0.5 | 3.0 |

| JX8525602028-3.2 | 8.5 | 2.5 | 2.8 | 60 | 20 | 0 | 0.5 | 3.2 |

| JX9028652030-3.5 | 9.0 | 2.8 | 3.0 | 65 | 20 | 0 | 0.5 | 3.5 |

| JX9528602030-3.8 | 9.5 | 2.8 | 3.0 | 60 | 20 | 0 | 0.5 | 3.8 |

| JX10525603020-4.0 | 10.5 | 2.5 | 2.0 | 60 | 30 | 0 | 0.5 | 4.0 |

| JE7025602020-2.8 | 7.0 | 2.5 | 2.0 | 60 | 20 | 4.0 | 0.5 | 2.8 |

| JE7525602030-3.0 | 7.5 | 2.5 | 3.0 | 60 | 20 | 4.0 | 0.5 | 3.0 |

JE8025602030-3.2 | 8.0 | 2.5 | 3.0 | 60 | 20 | 4.0 | 0.5 | 3.2 |

| JE8525602028-3.4 | 8.5 | 2.5 | 2.8 | 60 | 20 | 4.0 | 0.5 | 3.4 |

| JE9028652030-3.8 | 9.0 | 2.8 | 3.0 | 65 | 20 | 4.0 | 0.5 | 3.8 |

| JP802575U-4.0 | 8.0 | 2.5 | 75 | 0.5 | 4.0 | |||

| JP802575C-4.0 | 8.0 | 2.5 | 75 | 1.25 | 4.0 | |||

| JY802560-4.0 | 8.0 | 2.5 | 60 | 0.5 | 4.0 |

Ralated Products

Production process

Certification

Packaging: Non-fumigation wooden case or as per customer’s request.

Delivery Time: 20-30 working days after receiving advance payment.

Delivery Methods: By express, by sea or air.

Q1: Are you trading company or manufacturer ?

A: We are manufacturer (factory).

Q2: How long is your delivery time?

A: Generally it is 5-15 working days if the goods are in stock. Or it is 20-30 working days if the goods are not in stock, it is according to the quantity.

Q3. What is your terms of delivery?

A: FOB, CFR, CIF,EXW, DAP etc.

Q4: Do you provide samples ? Is it free or extra ?

A: No, it should be paid because of high value.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6: What is your terms of payment ?

A: Payment≤1000USD, 100% in advance. Payment≥1000USD, 30% T/T in advance ,the balance should be paid before shipment.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q8: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.