High Modulus Polyethylene HMPE 1600D Rope Fiber 1600D/440F UHMWPE

- Категория: UHMWPE Fiber >>>

- Поставщик: Shenzhen,Guodun,Armor,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.13 $* | 0.0 $* |

| Aug-17-2025 | 0.92 $* | 0.5 $* |

| Jul-17-2025 | 0.20 $* | 0.69 $* |

| Jun-17-2025 | 0.22 $* | 0.42 $* |

| May-17-2025 | 0.70 $* | 0.22 $* |

| Apr-17-2025 | 0.66 $* | 0.4 $* |

| Mar-17-2025 | 0.70 $* | 0.17 $* |

| Feb-17-2025 | 0.7 $* | 0.85 $* |

| Jan-17-2025 | 0.98 $* | 0.19 $* |

Характеристики

Product Description

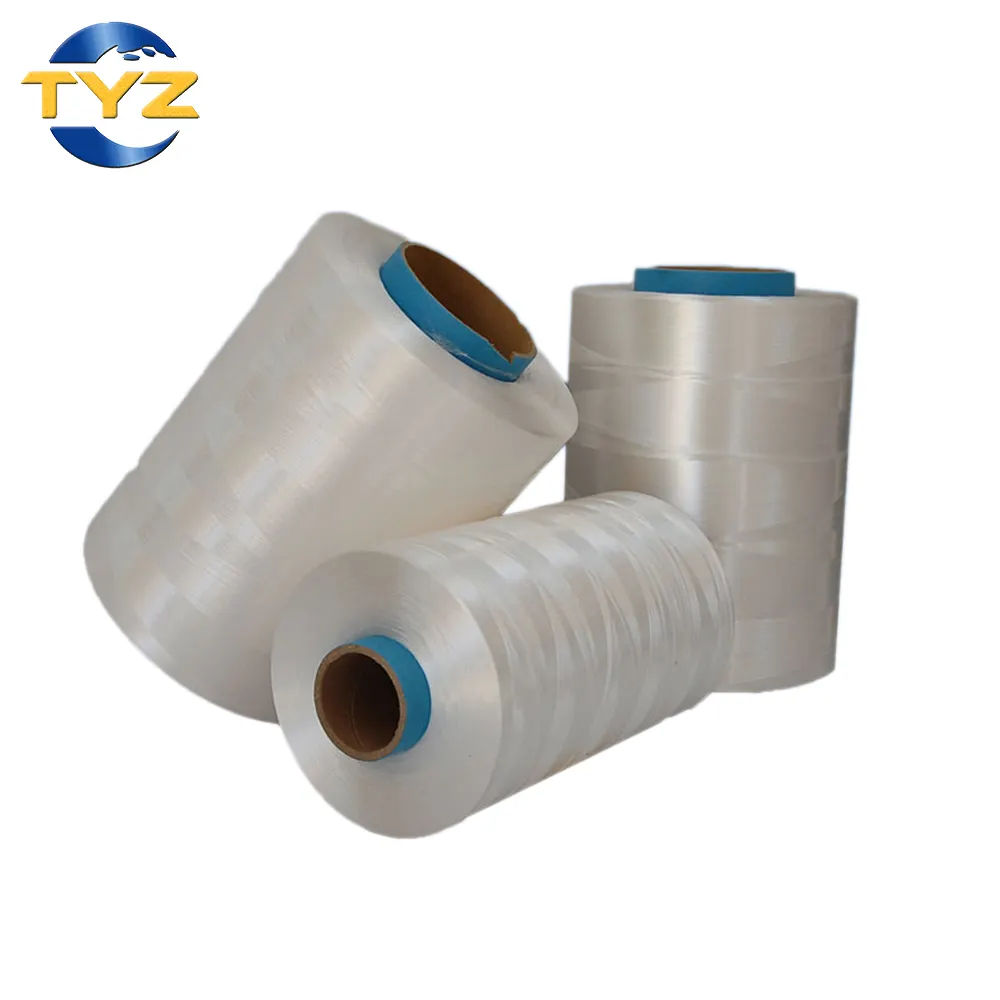

High Modulus Polyethylene HMPE 1600D Rope Fiber 1600D/440F

Typical Technical Properties:

1) After 1500 Sunshine hours, its remaining strength is more than 80%.

2) After 6 months in most chemicals (seawater, gas, etc), its remaining strength is 100%.

3) The UHMWPE ropes remaining strength is 100% after 1000 times loaded rotative test.

4) Its rotative times until break of Abrasion proof are more than 110 to 103.

5) Its rotative times until break of Winding proof are more than 240 to 103.

6) Its strength of annelation is 12 up to 18g/d. its 10 up to 15g/d for collusion.

7) Melting Point is around 135-145, Highly resistant to abrasion, cutting, tearing

8) Color is bright white and poor for dyeing.

STANDARD DELIVERY TYPES:

1. Design to coat / knit EN388 level 5 cut resistant gloves: 400D/240F

2. Design to make bulletproof or protective clothing: 600D/240F

3. Design to braid strongest ropes, cordages, fishing nets: 1200D/400F, 1600D/440F, 1800D/480F, 2400D/620F

For more detailed information, please contact us to get the catalogue and test report.

1) After 1500 Sunshine hours, its remaining strength is more than 80%.

2) After 6 months in most chemicals (seawater, gas, etc), its remaining strength is 100%.

3) The UHMWPE ropes remaining strength is 100% after 1000 times loaded rotative test.

4) Its rotative times until break of Abrasion proof are more than 110 to 103.

5) Its rotative times until break of Winding proof are more than 240 to 103.

6) Its strength of annelation is 12 up to 18g/d. its 10 up to 15g/d for collusion.

7) Melting Point is around 135-145, Highly resistant to abrasion, cutting, tearing

8) Color is bright white and poor for dyeing.

STANDARD DELIVERY TYPES:

1. Design to coat / knit EN388 level 5 cut resistant gloves: 400D/240F

2. Design to make bulletproof or protective clothing: 600D/240F

3. Design to braid strongest ropes, cordages, fishing nets: 1200D/400F, 1600D/440F, 1800D/480F, 2400D/620F

For more detailed information, please contact us to get the catalogue and test report.

Phoebe Zhu

Email: fiber@guodunarmor.com

Email: fiber@guodunarmor.com

Skype:phoebe@police21.com

Web: www.GuodunArmor.com

Web: www.GuodunArmor.com

Application

Certifications

Company Introduction

FAQ

1.Do you are factory or trading company?We have factory with 350000 square,pass the ISO90001:2008.

2.what's is your advantage?

*reliable--we are company that has 13 years UHMWPE manufacturing and exporting experience ,we delicate in Win-win .

*professional --we can offer the perfect products that exactly you want.

*Factory--we have factory,we offer you the best price.

3.Can you offer samples?

yes.

2.what's is your advantage?

*reliable--we are company that has 13 years UHMWPE manufacturing and exporting experience ,we delicate in Win-win .

*professional --we can offer the perfect products that exactly you want.

*Factory--we have factory,we offer you the best price.

3.Can you offer samples?

yes.

Похожие товары

TYZ High Strength Colored Uhmwpe Yarn 400D 440dtex

US $18.00-$25.00

СВМПЭ волокно 800D для пуленепробиваемого UD листа

US $18.00-$25.00

Полиэтилен с высоким модулем, волокно HMPE 1600D

US $30.00-$60.00