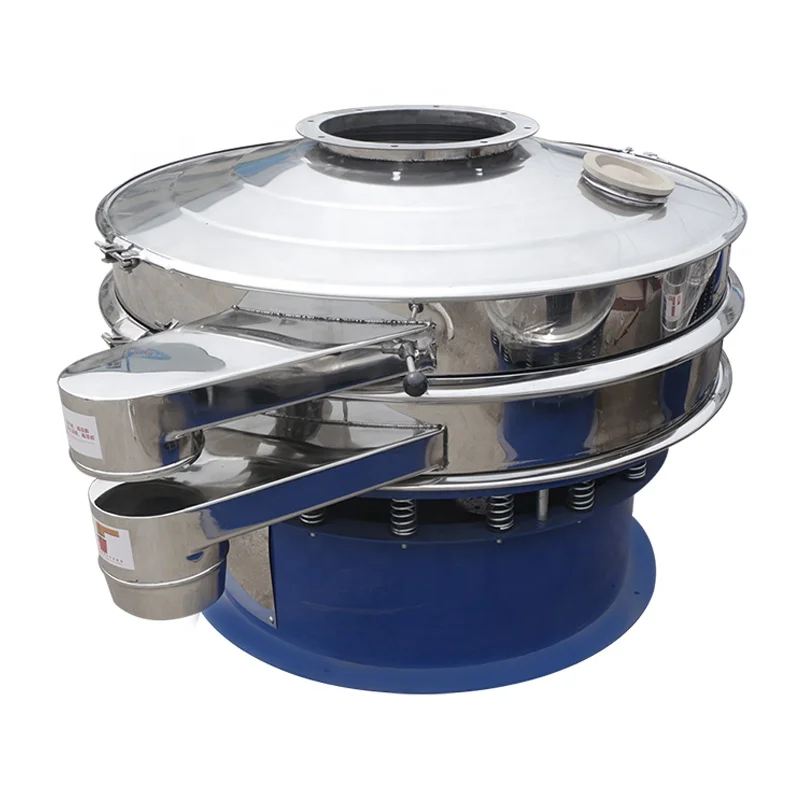

Автоматический просеивающий порошковый сортировочный вращающийся вибрационный экран для корма животных с

- Категория: Вибрационное сито >>>

- Поставщик: Henan,Chunying,Environmental,Protection,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.35 $* | 0.49 $* |

| Aug-16-2025 | 0.34 $* | 0.58 $* |

| Jul-16-2025 | 0.44 $* | 0.28 $* |

| Jun-16-2025 | 0.19 $* | 0.70 $* |

| May-16-2025 | 0.75 $* | 0.23 $* |

| Apr-16-2025 | 0.45 $* | 0.24 $* |

| Mar-16-2025 | 0.40 $* | 0.49 $* |

| Feb-16-2025 | 0.48 $* | 0.34 $* |

| Jan-16-2025 | 0.9 $* | 0.47 $* |

Характеристики

Automatic Sieving Powder Grading Rotary Animal Feed Vibrating Screen with ASTM Apparatus

Product Description

Rotary vibrating screen uses upright motor as the source of vibration, and it is equipped eccentricity hammer on the both sides of motor. Adjust the phase angle on the both sides of the top and bottom to change the movement orbits of the screen surface. It can be equipped with screen cloth cleaning device to avoid clogging effectively. The vertical horizontal and inclined movement of the machine, the track of materials on the screen can be controlled by adjusting the angle of the two eccentric weights.

Model | Power(kw) | Valid Diameter of screen(mm) | Volume(mm) | Layers |

CY-600-1S | 0.55kw | 550mm | 800*800*680 | 1 |

CY-800-1S | 0.75 kw | 750mm | 900*900*780 | 1 |

CY-1000-1S | 1.1 kw | 950mm | 1160*1160*880 | 1 |

CY-1200-1S | 1.5 kw | 1150 mm | 1360*1360*980 | 1 |

CY-1500-1S | 2.2 kw | 1450mm | 1850*1850*1130 | 1 |

CY-1800-1S | 3 kw | 1750mm | 2200*2200*1360 | 1 |

Product Advantages

1. To reduce or not produce clear screen time.

2. Do not produce powder pollution.

3. Keep the mesh size, stable screening accuracy.

4. Decomposition of adhesive material, reduce on the screen.

5. Reducing frequency of screening.

Using Scope

Rotary vibro sieve with CE certificate is widely used in: food, chemical, abrasive, ceramic, mining, paint, metallurgy, geology, defense and electronic industries such as pulp, powder and granule production grading and filtering.

Especially for the ceramic slurry sieve, its effect is more significant, the effect is much better, more efficient, screening number can also be improved.

Pre-sale service:

a. According the user’s different needs, we work to recommend and guide for them

b. To help them select the appropriate equipment

Service during sale:

a. Do good communication with customers, so that each part can exchang the information.

b. Deliver on time as per the contract clause.

After-sale service:

a. To track the customer’s feedback after receiving the equipment

b. Do well about the work of maintenance and service

Q:How to choose the suitable machine?

A:The proper selection of the vibrating screen depends on the material, number of layers, every mesh size, capacity, material moisture, viscous and corrosive etc:

Name and feature of the raw material?

Aim of using: get rid of impurity, filtration, grading

Handling capacity: kg /h, L/h

The raw material size: (mesh or mm)

How many final materials you want, or how many layer you need?

Local power supply (voltage and frequency)

Note: You had better send us the relevant pictures about the details.

Please Fill Out Your Inquiry To Get The Exact Quotation!