Прямые продажи с завода высокоэффективный сброс на водной

- Категория: Химикаты для очистки воды >>>

- Поставщик: Shanghai,Eastforever,Chemical,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.74 $* | 0.4 $* |

| Aug-16-2025 | 0.69 $* | 0.90 $* |

| Jul-16-2025 | 0.32 $* | 0.36 $* |

| Jun-16-2025 | 0.3 $* | 0.27 $* |

| May-16-2025 | 0.21 $* | 0.65 $* |

| Apr-16-2025 | 0.4 $* | 0.31 $* |

| Mar-16-2025 | 0.57 $* | 0.17 $* |

| Feb-16-2025 | 0.14 $* | 0.75 $* |

| Jan-16-2025 | 0.75 $* | 0.57 $* |

Характеристики

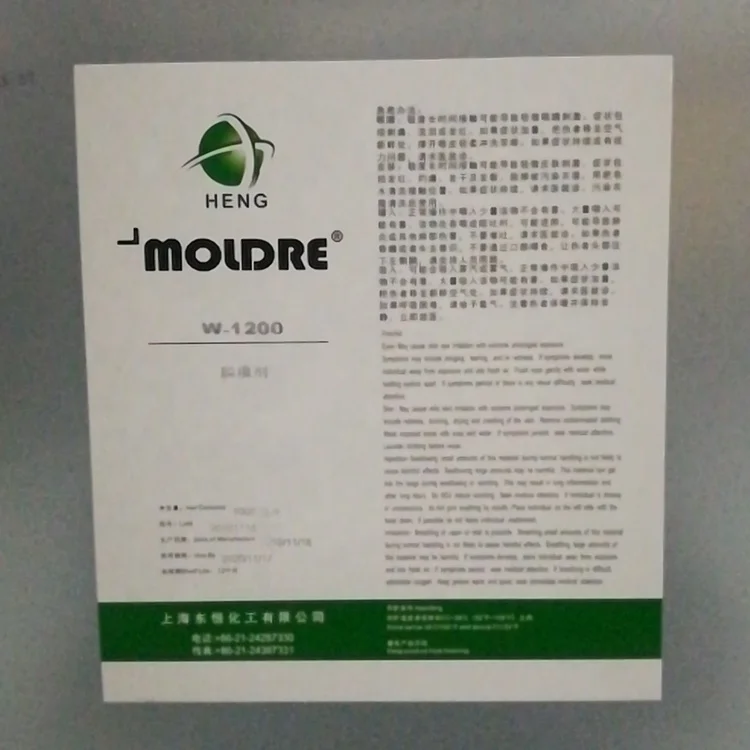

Factory direct sales high-efficiency release agent water-based release agent

| Alias | Mold release agent |

| Origin | China |

| Types | Syntheses Material Intermediates |

| Brand | MOLERE |

| Model | W-1200 water based release agent |

| Use | Mold release agent |

| Exterior | Liquid |

| MOQ | 1set |

| Appearance | white latex mold |

| temperature | 100-204 ℃ |

| Flash point | no flash point |

| bouquet | very weak |

| Note | under 40 ℃ to save |

| weight | 1.00 + / - 0.02 |

| Thermal stability after curing | 315℃ |

| Product advantages | Pollution transfer few,fast curing,Don't burn,Mold for many times,Low rework rate |

W-1200 is a water based semi-permanent release agent designed for rubber demoulding.In the correct coating on the preheated surface, it and the mold surface to produce a chemical combination, forming a layer of chemical inert, heat stable release agent layer, can be separated from all natural rubber and most of the synthetic rubber except fluorine glue and silica gel.

Mould ready

1.Mold surfaces should be thoroughly clean and dry.Any trace residue of the original release agent should be completely removed.Remove residual release agent can be cleaned with the mold water recommended by our company.Significantly thickened molds need to be polished (we can provide resin sand) to remove polymer residues and residual release agents.

2.Before spraying w-1200, the mold should be preheated to the lowest temperature of 100 ℃, and the maximum temperature can be 204℃. Operate the w-1200 with fine mist spraying mode. When the mold temperature is 60-150℃, adjust the spray gun so that the output is 90-120ml/ min, and when the mold temperature is higher than 150℃, the output is 120-150ml/min.At 100℃, release agent fully solidified after 10 minutes.At 150℃, w-1200 solidifies immediately, and full solidification takes 3-5 minutes.180℃ mold temperature, spray good, can immediately use.

Repair

Repair is needed when the release effect is poor.Reapply the mold release agent only where the release effect is poor to avoid mold thickening.The frequency of repair is affected by polymer type, mold formation and friction parameters.Follow the procedure above.

|  | |

|  |