Карбид вольфрама Kongsberg биты ESKO лезвие ножа

- Категория: Packaging Machinery Parts >>>

- Поставщик: Xiamen,Pktol,Advanced,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 24.35 $* | 25.15 $* |

| Aug-17-2025 | 24.9 $* | 25.81 $* |

| Jul-17-2025 | 20.65 $* | 21.80 $* |

| Jun-17-2025 | 23.82 $* | 24.12 $* |

| May-17-2025 | 20.20 $* | 21.85 $* |

| Apr-17-2025 | 23.0 $* | 24.8 $* |

| Mar-17-2025 | 23.32 $* | 24.65 $* |

| Feb-17-2025 | 22.38 $* | 23.0 $* |

| Jan-17-2025 | 22.4 $* | 23.52 $* |

Характеристики

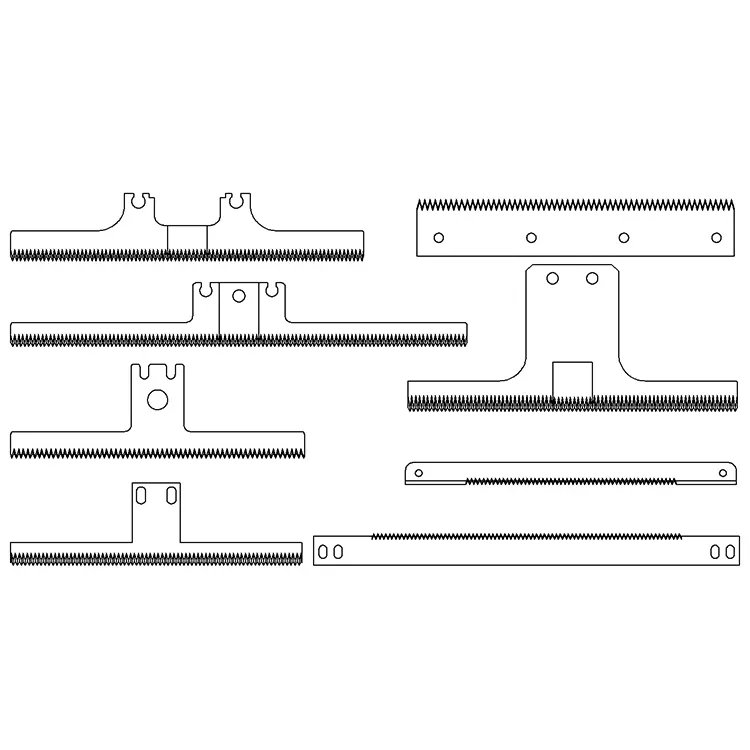

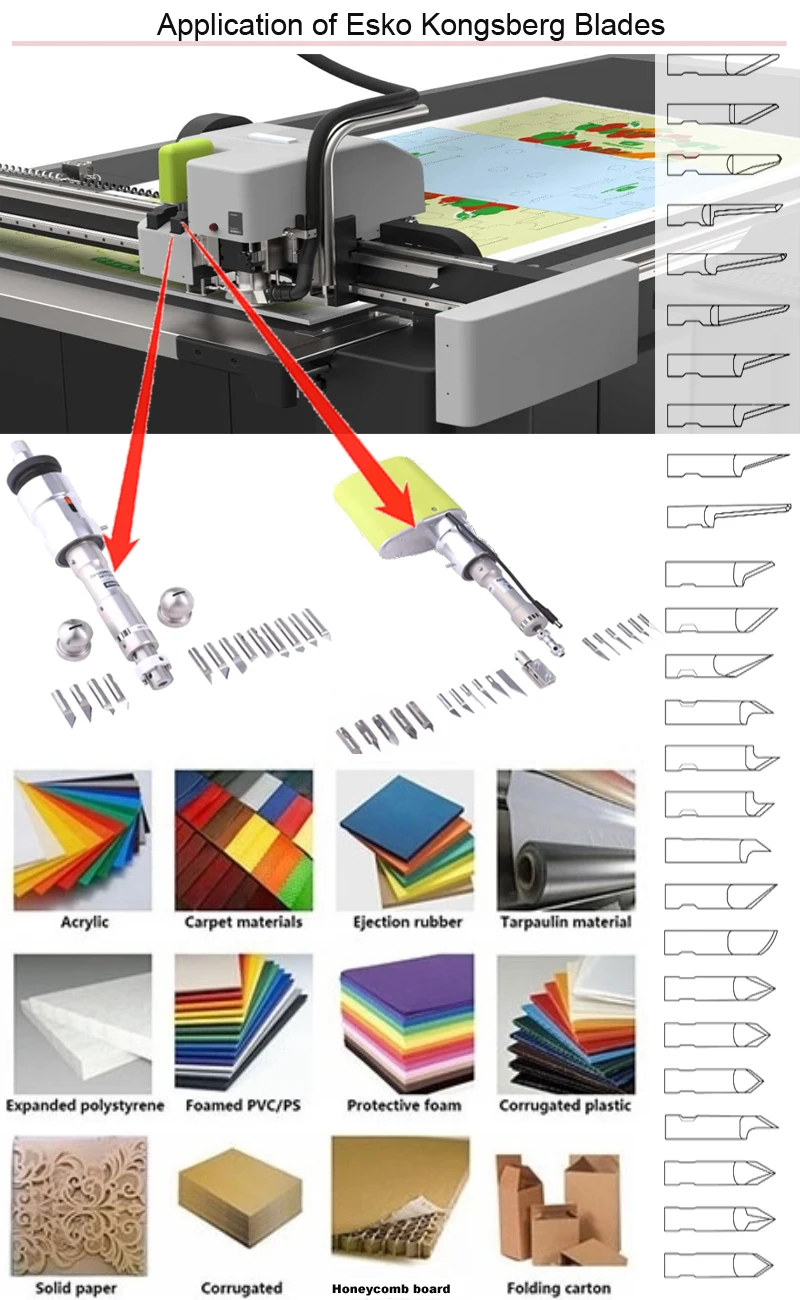

Long life tungsten carbide blade for thinner flexible materials such as folding carton, polyester film, leather, vinyl and paper. For use in the RM Knife tool. Length: 40mm. Cylindrical 8mm. Maximal cutting thickness about 6,5mm. 30' cutting edge.

Place of Origin: | China (Mainland) | Brand Name: | PKTOL | ||

Product name: | BLD-SR8172, Oscillating Blade | Type: | for Esko kongsberg cutter | ||

Material: | Tungsten Carbide, YG8X, YG10X, YG12X etc. | Shank Diameter: | 6mm, 8mm | ||

MOQ: | 50 pcs | OEM service: | Available | ||

Tolerance: | Length±0.2mm; Width±0.05mm; Thickness of edge±0.02mm | ||||

Packing: | Simple packing/Plastic box packing/Blister packing | ||||

10 years experience

1). Size standard or as per your requirements;

2).Very advantageous price.

3).Good English communication;

4).Professional technology on product;

5).Could accept trial order.

Quality guarantee

1). High-quality raw materials and years of processing and production experience ensure stable product quality;

2). Strict inspection process to ensure that each product is qualified.

24-hour service

1). 7×24 hours online service, tracking the progress of the order at any time, and timely feedback to the customer.

2). Provide other services to customers

Quality and service

1). Quality Inspection and Warranty

China Cutting Edges products are strictly checked over 20 inspection process from powder to completed. We can keep and improve our quality, and are very pleased to hear that customers are satisfied with PKTOL stabilized products.

2). OEM &ODM Service is highly welcomed.

1)customized Logo/Brand;

2)help products design;

3). When the order is confirmed, all the drawings and samples will be converted into CAD drawing. We will arrange time

schedule for producing customer order after design drawings are confirmed by both parties. During the producing period, we will update tracking and recording progress and feedback to customers regularly.

Q1. How do you control the quality?

A: First control is 100% raw material from WC supplier, 100% inspecting throughout each process. Importing state-of-the-art CNC machines and inspecting equipment from Germany and Japan. Continuous training for experienced engineers and workers.

Q2. How can I choose the right TC Grade for the carbide products?

A: If you cannot confirm which TC grade is right for your products, please kindly provide us with your purpose of usage, we would suggest the most suitable grade for you.

Q3. Why the short working life time of corrugated board knives?

A: 1. Is the grain size of the grinding wheel proper? Too coarse grain size of grind wheel: make a short working life time of knives.

2. Too frequent grinding; the grinding time is too long, or the grinding pressure is too high.

Q4. Why the edge of corrugated boards cut by knives with burr and dent?

A: 1. Please check the cutting edge of your blades. Is the cutting-edge keen enough?

2. The corrugated board is too wet.

Q5. Why the knife break?

A: 1. Improper assembly (e.g. deformed flange plate; improper screwing) will cause the quick break of blades. Any improper touch of the blades is strictly prohibited during the working.

2. Unstable swing grinding wheels break the knives, please check the bearing of grinding wheels.

3. Improper touch or strike with other hard things.

4. Accident collision of knives.

Q6. Why chips on the cutting edge after the grinding?

1.Unstable swing grinding wheels may cause this problem, even break the knives.

2. The strike of hard things may cause the chips on the cutting edge.

Q7. Why the edge of corrugated board is not straight?

A: Unmatched strength of the knives for the corrugated board with high density.

We hope that this information will help you. If you have any other questions, please call our 24-hour service hotline or you can leave a message on this website or via E-mail contact with PKTOL.