Печатная машина оборудование для пост-прессования Автоматическая ИК-сушилка кварцевой вспышки устройство

- Категория: Post-Press Equipment >>>

- Поставщик: Guangzhou,Disen,Electromechanical,Equipment,Co.,Ltd

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 6664.59 $* | 6997.0 $* |

| Aug-16-2025 | 6608.37 $* | 6938.88 $* |

| Jul-16-2025 | 5544.40 $* | 5821.18 $* |

| Jun-16-2025 | 6496.25 $* | 6821.69 $* |

| May-16-2025 | 5656.31 $* | 5939.34 $* |

| Apr-16-2025 | 6384.13 $* | 6703.17 $* |

| Mar-16-2025 | 6328.73 $* | 6644.76 $* |

| Feb-16-2025 | 6272.58 $* | 6586.31 $* |

| Jan-16-2025 | 6216.0 $* | 6527.44 $* |

Характеристики

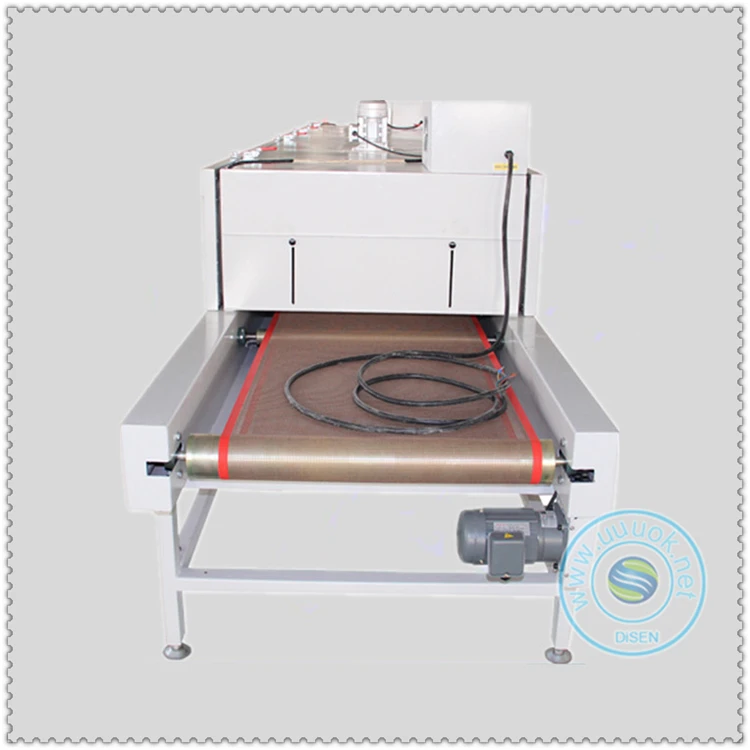

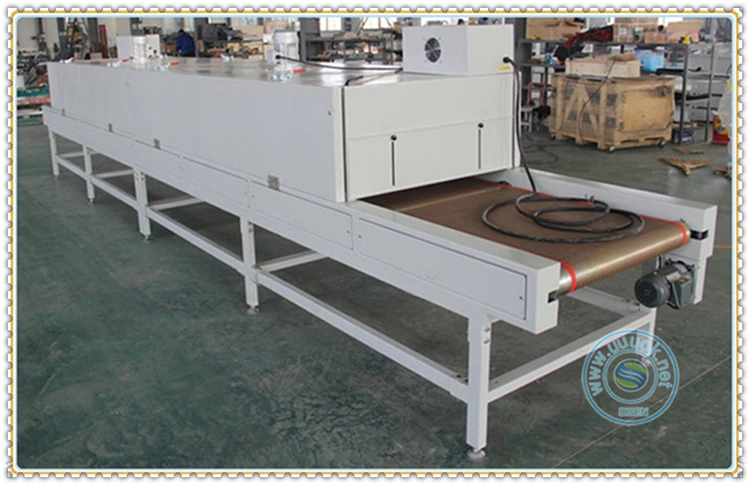

Feature description Application / Application Model: DSS-XF60100 Tunnel Dryer |

Screen printing refers to the use of a screen as a substrate, and through the photosensitive plate making method, a screen printing plate with graphics. Screen printing consists of five major elements, screen plates, squeegees, inks, printing stations, and substrates. The mesh of the screen printing plate can be transmitted through the ink, and the non-image portion of the mesh can not be printed through the basic principle of the ink. When printing, the ink is poured into one end of the screen printing plate, and a certain pressure is applied to the ink portion on the screen printing plate by the squeegee, and at the same time, the other end of the screen printing plate is moved at a constant speed, and the ink is scraped from the graphic during the movement. Part of the mesh is squeezed onto the substrate. screen printing flash dryer,automatic flash dryer,infrared flash dryer,t-shirt screen printing flash dryer,silk screen flash dryer,flash dryer auto,flash dryer lamp,flash dryer ir lamp.flash cure dryer,auto ir quartz flash dryer flash cure unit flash dryer.

Screen printing has the advantages of large batch size, low price, bright color, long shelf life and fast delivery. It is recognized by more and more industries and widely used. In the circuit boards of household appliances, patterns on textiles, T-shirts, cultural shirts, patterns on shoes, refrigerators, televisions, text on washing machine panels, decoration on ceramics, glass, wall tiles; various commercial advertisements , packaging, outdoor, fixed, mobile and other advertising platforms; in the packaging and decoration industry, high-end packaging boxes, packaging bottles, cigarette packets, wine bags, especially the super large outer packaging and product shape decoration - screen printing applications are abnormal Widely connected with our lives, its technology is mainly controlled by many printing houses, and the small and personalized screen printing technology is rarely taught in China, and the market is extremely broad! screen printing flash dryer,automatic flash dryer,infrared flash dryer,t-shirt screen printing flash dryer,silk screen flash dryer,flash dryer auto,flash dryer lamp,flash dryer ir lamp.flash cure dryer,auto ir quartz flash dryer flash cure unit flash dryer.

Screen printing consists of five major components, namely screen plates, squeegees, inks, printing stations, and substrates. The basic principle of screen printing is to use the basic principle of the screen printing part of the mesh to penetrate the ink, the non-image part of the mesh is not transparent to the printing. The ink is poured on one end of the screen printing plate during printing, and a certain pressure is applied to the ink portion on the screen printing plate by the squeegee blade while moving toward the other end of the screen printing plate. The ink is squeezed from the mesh of the graphic portion onto the substrate by the squeegee during movement. Due to the viscous action of the ink, the imprint is fixed within a certain range. During the printing process, the squeegee is always in line contact with the screen printing plate and the substrate, and the contact line moves with the movement of the squeegee due to the screen printing plate and the substrate. A certain gap is maintained between them, so that the screen printing plate at the time of printing generates a reaction force against the squeegee by its own tension, and this reaction force is called a resilience force. Due to the resilience, the screen printing plate and the substrate are only in a moving line contact, and the other portions of the screen printing plate are separated from the substrate. The ink and the screen are broken and the printing is ensured to ensure the dimensional accuracy and avoid the dirty substrate. When the squeegee scrapes across the entire layout, it is lifted, and the screen plate is lifted, and the ink is gently scraped back to the original position. This is a printing trip. screen printing flash dryer,automatic flash dryer,infrared flash dryer,t-shirt screen printing flash dryer,silk screen flash dryer,flash dryer auto,flash dryer lamp,flash dryer ir lamp.flash cure dryer,auto ir quartz flash dryer flash cure unit flash dryer.

|