Машина для измельчения и соковыжимания груши 1 5 т/ч/машина производства фруктового

- Категория: Fruit & Vegetable juicer machine >>>

- Поставщик: Zhengzhou,Hento,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.96 $* | 0.70 $* |

| Aug-16-2025 | 0.28 $* | 0.19 $* |

| Jul-16-2025 | 0.64 $* | 0.67 $* |

| Jun-16-2025 | 0.68 $* | 0.4 $* |

| May-16-2025 | 0.89 $* | 0.48 $* |

| Apr-16-2025 | 0.14 $* | 0.57 $* |

| Mar-16-2025 | 0.85 $* | 0.22 $* |

| Feb-16-2025 | 0.69 $* | 0.81 $* |

| Jan-16-2025 | 0.90 $* | 0.87 $* |

Характеристики

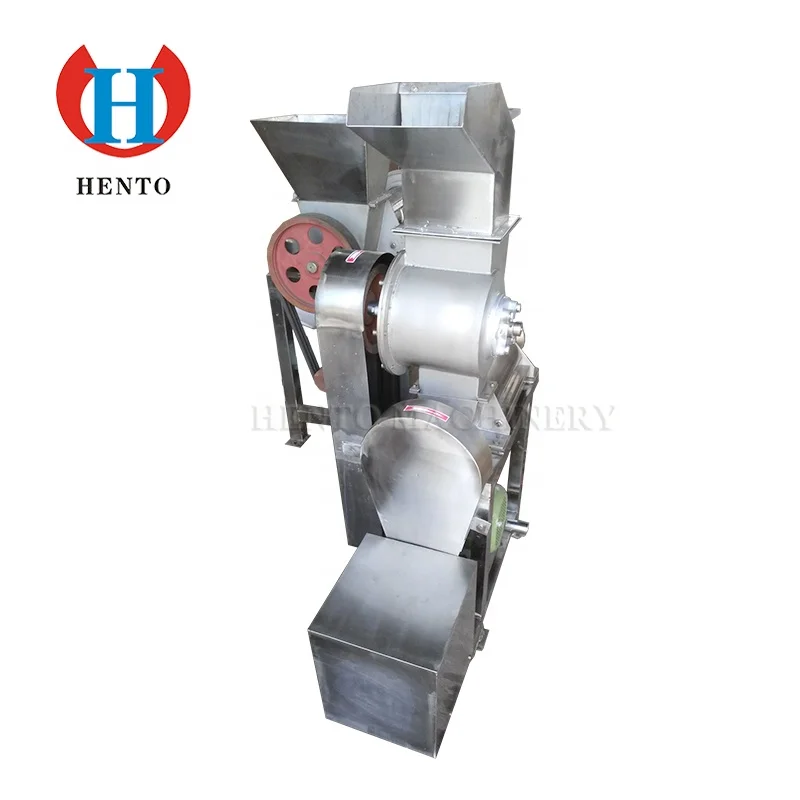

1.5T/H Pear Crushing and Juicing Machine / Fruit Juice Making Machine

The unit is suitable for all kinds of berry,kernel fruitand and vegetables, crush and juice at the same time, also can do the other larger fruit and vegetables cooked to soften for juicing. (tomato juice yield reached 45% ~ 45%).

The main component of this equipment is the hopper installed on the crushing plant. There are four groups of fly knife on the rotor, a group dead knife. Fly knife around its own axis in the bottom of a stationary knife gap in rotation. So that fruits and vegetables get broken particle size 2-5 mm,directly into the spiral juicing system,in order to improve the juice result. Then do screw spiral juicing,Spiral path along the bottom slag is expected to export direction gradually increase and screw Distance gradually reduce. When the material is spiral propulsion, for spiral cavity volume shrinking, form for material crushing. Screw spindle rotation direction from the feed hopper to slag trough direction, as the clockwise direction.

Raw material added to the feed hopper,under the propulsion of screw press,the squeezing the juice through the filter into the bottom of the juice machine,Waste is expelled through screw and annular gap formed between the conical part ,Regulating head along the axial movement cam adjust the gap size.Change the size of the gap,can change slag yield.

The structure diagram

1,Crusher boday

2,Broken shaft

3,Fracture of the stator

4,feed hopper

5,Crush rotor

6,side cover

7,Crush sword

8,Spiral juice machine

Installation operation and maintenance

1. The machine must be installed level, and the ground screw fixation.

2. When the device is started,should adjust the largest head make the annular gap,Then gap decreases,After reaching the technological requirements, with a fixed wheel brake bearing seat position.

3,Feed must be uniform,It is forbidden to hard foreign body into the hopper, so as not to damage the screen.

4,After each class job must wash with water and brush filter. If the fiber is more fine filtration of fruit juice,Must be according to the condition of production, increase a wash between network, squeezed the after all with hot water washing machine.

5,Replaced periodically loaded with embellish clean grease, bearing normal temperature less than 75 ℃

Application and usage:

Use to squeeze vegetables, celery, spinach, tomato, pineapple, pear, apple and orange and other fruit and vegetable juices.

Model | Capacity T/h | Power Kw | Size mm |

HT-PZJ-0.5 | 0.5 | 2.05 | 900*350*1100 |

HT-PZJ-1.5 | 1.5 | 5.5 | 1500*450*1640 |

HT-PZJ-2.5 | 2.5 | 12.5 | 1600*700*1760 |

If you need further information, please contact us freely, we will do our best to cooperate with you. Our contact information is as follows: