Электрический нагревательный комбинированный резервуар из нержавеющей стали с 3 сосудами для пивоварения 500л 5HL

- Категория: Other Beverage & Wine Machines >>>

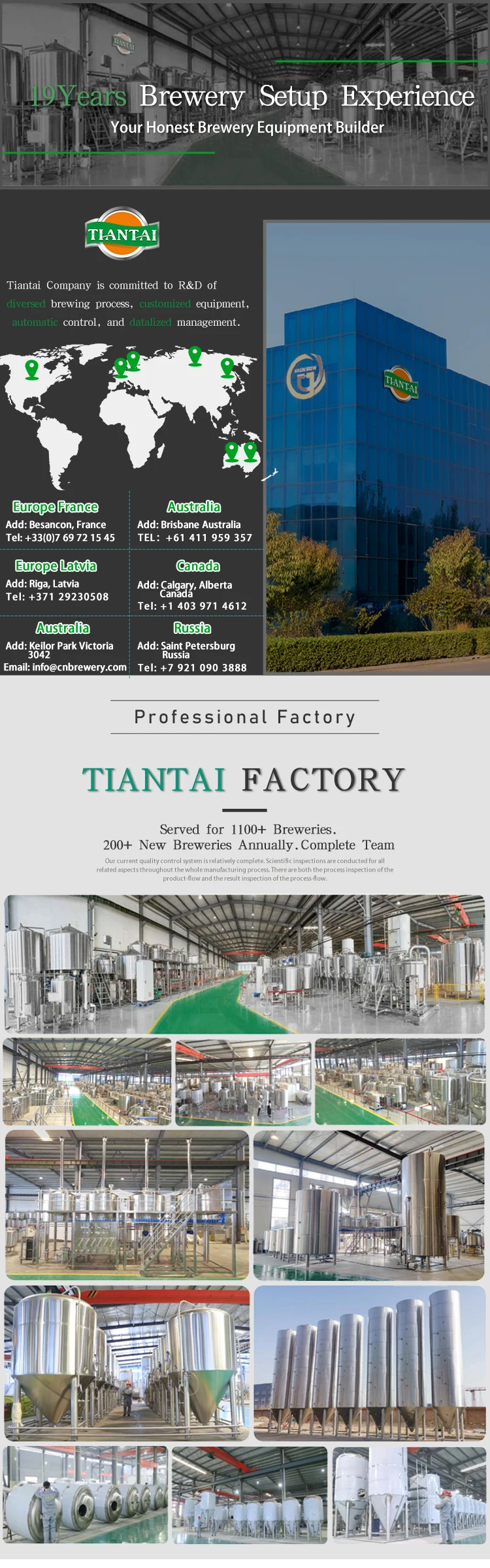

- Поставщик: Shandong,Tiantai,Beer,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 63725.5 $* | 66911.74 $* |

| Aug-17-2025 | 63189.53 $* | 66348.83 $* |

| Jul-17-2025 | 53015.23 $* | 55666.94 $* |

| Jun-17-2025 | 62118.28 $* | 65224.6 $* |

| May-17-2025 | 54086.42 $* | 56790.73 $* |

| Apr-17-2025 | 61047.76 $* | 64099.70 $* |

| Mar-17-2025 | 60512.29 $* | 63538.52 $* |

| Feb-17-2025 | 59976.19 $* | 62975.23 $* |

| Jan-17-2025 | 59441.30 $* | 62413.41 $* |

Характеристики

500L 5HL 4BBL Stainless steel electric heating combined 3 vessel brewing tank

1.Description:

500L 5HL 4BBL Stainless steel electric heating combined 3 vessel **** is often used in small craft breweries or craft brewing bars. The system contains combined three vessels, a Mash/Lauter&Whirlpool Tun and a kettle tank. The mashing process and the wort filtration process are completed by the combined top tank, the boiling is completed by another tank, and the whirlpool processes are completed by the combined bottom tank. With such configuration, saving equipment costs and floor space. This system usually brews one batch a day. If the second batch of brewing takes at least 14 hours, it can cope with a temporary increase in production and is not suitable for planned multi-batch brewing in one day. According to different fermentation cycles of brewed beer, 6pcs 1000L fermenters or 12pcs 500L fermentors can usually be configured, and 4pcs 1000L fermenters and 4pcs 500L fermenters can also be configured to meet the needs of various beer types. The system also needs to be equipped with a complete automatic or manual control system, malt milling system, CIP system, cooling system, air system, etc.

2.Our Advantage:

With ISO TUV SGS, the product meets the GB/CE/PED/ASME standard

Local service in EUROPE, AUSTRALIA ETC

5 Years Warranty for tanks

0 trade risk verified by more than 1100 breweries

Build breweries in 76 countries

19 years experience

3.Features

Combined three vessels, 500Liter/batch, first batch takes about 8 hours, and two batches of 14 hours are allowed;

All certificated 304 stainless steel, easy to clean; Copper cladding for special environments such as bars;

Electric heated, high thermal efficiency; Steam or direct fire heating option;

The wort cooled by tap water and -5 ºC ice water to cool in two stages, Single stage available;

Mashing heating and fermentation cooling automatically controlled, and manual control switched at any time;

Manual valve control, humanized operation, low equipment investment cost, high cost performance; PLC automatic control for upgrade;

Beer filling in stainless steel beer barrels, glass bottles or cans;

4.Technique Details:

Part 1: 300-500kg/hr Malt Milling Unit | ||

| 300-500kg/hr Malt Miller | 1set |

| Flexible Auger | 1set |

| Milling Controling Cabinet | 1set |

Part 2: 500L Combined Three Vessels Brewhouse | ||

| 5HL Mash/Lauter&Whirlpool Tun | 1set |

| 5HL Kettle tank | 1set |

Part 3: Fermentation Unit | ||

| 1000L Fermentation Tank/Unitank | 4sets |

| 500L Fermentation Tank/Unitank | 4sets |

| 1000L Bright Beer Tank | 1set |

| 500L Bright Beer Tank | 1set |

Part 4: Glycol Cooling Unit | ||

| 1000L Glycol Water Tank | 1set |

| 3HP Glycol Water Chiller | 2sets |

| Glycol Water Pipeline | 1unit |

Part 5: Electric Control Unit | ||

| Brewhouse Control Cabinet | 1set |

| Fermentation Control Cabinet | 1set |

Part 6: 100L Portable CIP Cart [Two Tanks] | ||

| 100L Single Wall Caustic Tank | 1set |

| 100L Single Wall Acid Tank | 1set |

| Sanitary Centrifugal Pump | 1set |

Part 7: Keg Filling Unit | ||

| 1-Station Keg Filler | 1set |

| 2-Station 2-Tank Auto Keg Rinser | 1set |

Part 8: Bottle Filling Unit | ||

| 8-Station Semiauto Bottling Machine | 1set |

Part 9: Other Auxiliary Equipment | ||

| Compressed Air Supply | 1set |

>>>>>>>Click here for a free quotation now!

| a.) Free consultation service before, during, and after sales; | ||||||

| b.) Project planning and design services; | ||||||

| c.) Free debugging instruction of equipment until everything is functional; | ||||||

| d.) Management of equipments' long distance shipping from seller's factory to named port or station by buyer; | ||||||

| e.) Training of equipment maintenance and operating personally; | ||||||

| f.) New production techniques; | ||||||

| g.) Provide 60 months complete warrantee for main parts and life-time maintenance service;The seller is responsible for the nature damage of the machinery in the warranty period except for man-made damage. All spare parts and wearing parts are attached with the machinery for free; |